Automation has always played a particularly large and decisive role here in order to be able to reliably meet the constantly growing demand. For a long time, however, automation was limited to individual production lines. But these cannot react smartly, independently and flexibly to changing requirements such as fluctuating demand, changing quality requirements or other factors. This has always required human intervention and time-consuming manual coordination between purchasing, sales, warehouse and production and along the entire value chain. Also, necessary maintenance work is often only noticed very late, which leads to high downtimes due to defects and wear of individual highly integrated components.

Finally, for example classic bottling plants, let alone their individual components such as encoders and slip rings, usually do not receive any automated real-time data from the enterprise resource planning system, for example to adjust the operating parameters automatically and to control new production orders on the basis of data. And their individual components do not transmit any data about their own condition or their optimal operating parameters, which they have also “learned” on their own. Full-scale condition monitoring is thus not possible, nor is the independent and data-based optimisation and control of production processes. The collection and transmission of this operating data between all parts of the plant is the basic prerequisite for this. This increases the amount of data transmitted and the required transmission speed. Only in this way is a high-performance, self-organising and thus also resource-saving Food Industry 4.0 possible.

Together with the increasing online demand, stronger fluctuations in stationary trade and topics such as “zero waste”, energy transition and gas price explosion, these weaknesses of classic automation lead to more and more problems. This is because achieving these goals requires fine-tuning with ever-increasing frequency, which classic industrial automation cannot do. Automation is device-oriented, while smart and networked products are developed in the context of the Industry 4.0 and in the IoT a holistic system view enable. This is the only way to minimise downtimes and accelerate individual processes. Key factors for future existence on the world market.

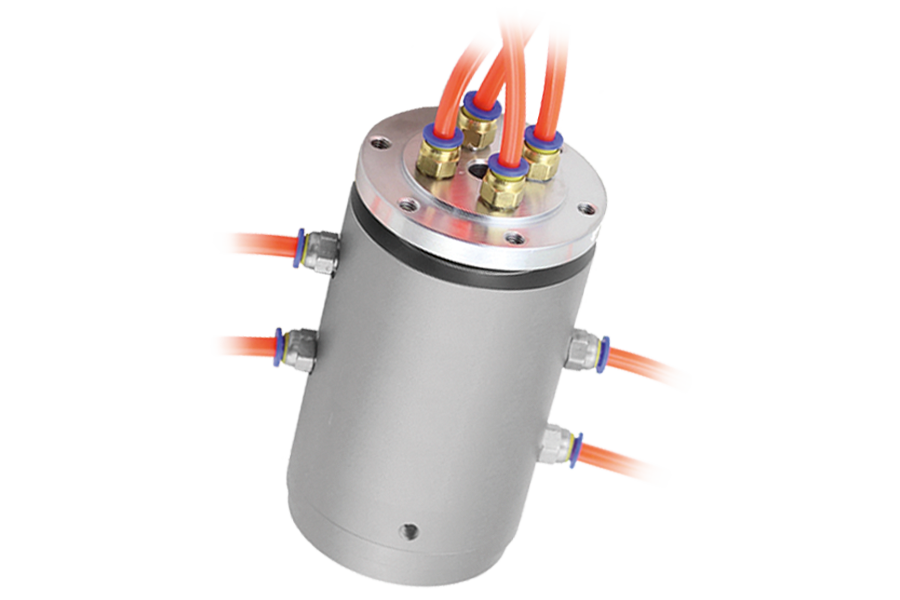

Each component in the Smart Factory of the future, right down to the slip ring, must understand, through sensors and integration into a holistic network, what its own role is, how good its own condition is and how it can best react to changing requirements, all in real time. For this, however, rotating unions and slip rings must no longer only be able to transmit power and media, but also to both transmit and generate data and signals themselves. And reliably at that.

This is also referred to as the Condition-Monitoring. Slip rings with their own sensor technology can, for example, measure axis movements, vibrations and temperature and transmit this data, as they are highly integrated components within a production machine. This data can then be analysed in real time and additionally processed in so-called “data loggers”. Lifetime-Histograms from which the slip ring and machine learn independently how to function best and for the longest time. In addition, it is possible to maintenance effort in good time, while maintenance cycles lengthen at the same time.

The reasons for these growing demands are manifold. But above all, rising production costs, the requirements of climate protection and food safety and the strong fluctuations in demand make it necessary not only to produce, pack and check large quantities fully automatically, but also to do so as dynamically, resource-efficiently and safely as possible.

While buzzwords such as “artificial intelligence” and “machine learning” are being Filling and packaging plants will probably not be superfluous for a long time yet. But in order to remain future-proof and competitive on the global market, production must become more versatile and be able to react more flexibly to fluctuating demand, for example to reduce overproduction and recalls. Quality assurance can also benefit from Industry 4.0 and automation.

However, the basic building blocks of a world and also of an industry on the move are still Slip rings and Hybrid rotating unions. And just as algorithms will never replace packaging plants and filling lines, but will complement them, there is no replacement yet in sight that can reliably and selectively Transmission of data, power, signals and fluids between rotating and fixed components better than slip ring assemblies. But they too are changing in the context of the fourth industrial revolution and the demands placed on them are growing.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Requirements for slip rings and rotating unions in the Smart Factory

Space saving plays a role in every industry. This often starts with the fact that numerous Individual processes on rotary indexing tables be executed. Slip rings and/or (hybrid) rotary unions are necessary so that the plant components installed on one can be supplied with electricity as well as receive and transmit data to peripheral components. This applies, for example, to filling systems, from filling to labelling and capping. and the space saving also applies to the slip rings themselves. The feedthrough and Transmission of fluids, data, current and signals must be as combined take place.

Slip rings in the food industry 4.0 must therefore first of all function as maintenance-free as possible, be very variable in rotation speed (rpm), space-saving and easy to clean. This means that production must be interrupted as rarely and as briefly as possible, for example to make fine adjustments to the operating parameters or to carry out maintenance work.

The Condition-Monitoring enables maintenance needs to be identified in good time so that, if possible, no complete replacement of a component is necessary, which would usually mean long downtimes. In addition, the slip rings learn through generated data how they can positively influence their own operating parameters in order to reduce maintenance in the future. For this, integrated sensor technology is necessary so that the slip rings actually »Industrie 4.0 ready« are.

In addition, hybrid slip rings must combine more and more functions in just one component. Whether it’s the fastest data transmission with the help of Fibre optics, USB connections, industrial Ethernet or video signals, they all want in addition to the classic media feed-through and power transmission be integrated. The data transmission must be reliable and fast. Likewise, currents of 120 A and more have to be transmitted in some cases, while these do not affect the Transmission of the Ethernet data may have an effect. Accordingly, the choice of network cable and shielding (CAT) is also decisive here. Our Ethernet Slip Rings are capable of handling both high currents and data with up to 1000Mbit/sec without loss and with minimal noise (max 10mΩ) in only one slip ring. Namely independent of the Ethernet protocol used (PROFINET, Sercos III, Powerlink, EtherCAT, MECHATROLINK-III and much more.).

And also the Requirements for rotating unions are increasing. Increasingly, they too must not only be able to transmit media such as emulsions, oil, water or other liquids with high separation accuracy and in combination in multi-channel rotary unions, but also additionally electrical power and signals, such as Video signals, Ethernet signals, Profinet, KOAX, HD-SDI and fieldbuses. In this way, a rotating union can combine several media and, in addition, the contactless power transmission of the classic slip rings, so that it can also be used for the Plant control and monitoring of production to be able to be used. For this, a high degree of customisability, for example in sealing rings and materials, is crucial.

Growth forecast & Facts about the food industry in Germany

Given the growing world population, the food and beverage industry is expected to grow steadily in the coming years. Although there was a slight decline in sales and employment figures in the Corona year 2020, the growth trend continued as early as 2021. But at the same time, new goals are coming into focus, especially the increase of food safety, flexible reaction to dynamic demand situations, especially through online trade, and an overriding goal that goes hand in hand with this: Zero Waste.

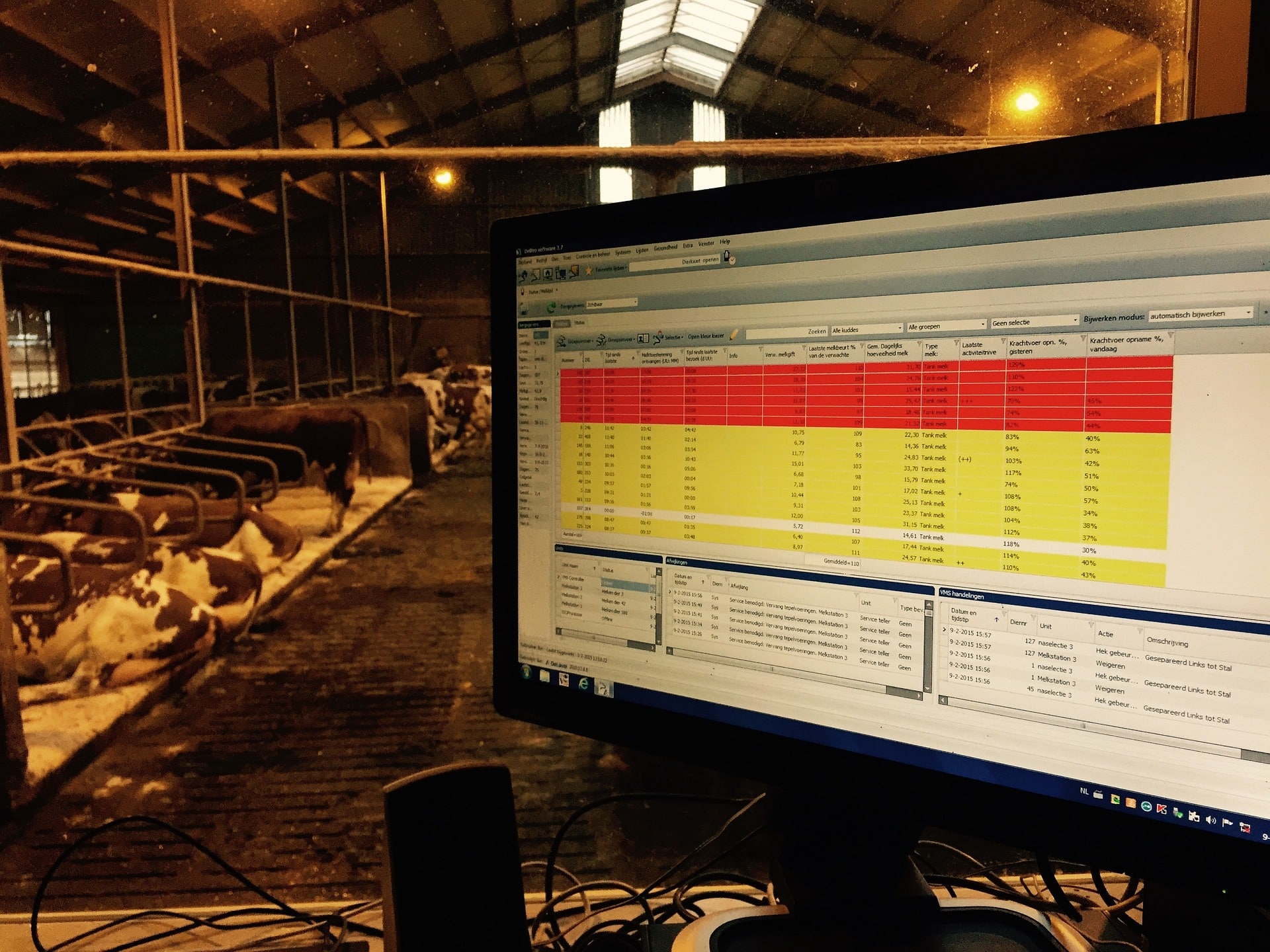

The smart linking of sales data, production figures and various merchandise management systems so that they can have a fully automated effect on the utilisation and control of production facilities is essential for this.

What happens from 2022 to 2027?

2022 the turnover of the entire food market in Germany (not only the manufacturing industry) was approx.. 200 billion euros. For comparison: the largest food market in the world in 2022 is China, with a sales volume of 1,126 billion euros.

4 % of this volume have already been achieved in Germany in 2022. online is generated. By the way, this share is expected to increase to 9 % to 10 % by 2030. It is therefore becoming more important for manufacturers to be able to react flexibly to online orders, as these also influence the quantities demanded by wholesalers and retail chains. And this is where the Trends tilt quickly.

For example Meat still by far the most important largest market segment (approx. 46 billion euros), but other areas are catching up. Compared to 2020, meat consumption per capita has already fallen by 2.2 kilograms. dropped to 55 kilograms per year. This is the lowest value since recording of meat consumption began in 1989. Incidentally, Germans consume a total of about 592 kilograms of food per capita and per year. This corresponds to a turnover of about 2,400 euros per person. For2023 sales growth of about 6 % is expected.

Until 2027 For Germany, a market volume of over 240 billion euros predicts (CAGR 2022-2027). The amount of food produced is then estimated at approx. 55 million kilograms lie.

Despite the growing volume, production must simultaneously focus on goals such as zero waste and climate protection, as well as food safety. Due to government regulations, the food and beverage industry must follow strict procedures in terms of cleanliness, health, safety and environmental ethics. Components that communicate with each other allow the industry to better plan and predict.

rotarX slip rings are therefore designed specifically for such applications and can make the decisive difference especially in the areas of performance, durability, reliability and speed of data transmission, as well as customisability and freedom from maintenance. Grown from slip ring solutions for Wind turbines, for which the recording and transmission of wind power-specific data such as shock and vibration, as well as robustness against extreme temperature differences and a design that is as maintenance-free as possible (especially for offshore turbines) are particularly important, it is becoming increasingly apparent that such solutions also offer decisive advantages for the food industry of the future.

Zero Waste - 11 million tonnes of food per year are destroyed

Not only is meat consumption decreasing, but sensitivity regarding packaging and food destruction is also increasing. After all, in Germany almost 11 million tonnes of food destroyed per year, which is almost exactly 20% of the total production of 55 million tonnes projected until 2027. And the reason for this huge amount of food waste is almost always a incorrect calculation. This is not only costly, but also offers enormous savings potential in terms of energy consumption.

One of the main reasons for food waste is the current philosophy of large retail chains that the shelves must always be full by closing time. This leads to thousands of employees in thousands and thousands of shops running through the aisles every evening and having to throw away and sort out heaps of food. There are many approaches to solving this problem, but one of the most important is the use of artificial intelligence. A very interesting and Representative survey of the digital association Bitkom has revealed that the majority of retailers believe artificial intelligence is able to Eliminate food destruction completely in Germany.

If the primary cause of food destruction is miscalculation by consumers, retailers and industry, no component can solve the problem as well as a smart factory equipped with a gigantic treasure trove of data and reliable computing power. For example, AI can accurately predict which quantities and, above all, which products consumers will buy in the future, down to the day of the week and possibly even the time of day. Software companies like Blue Yonder have already convinced retail chains like dm and Kaufland of this approach. For example, the company’s AI is already being used at Kaufland’s meat counters. The algorithm takes into account more than 300 different factors to accurately forecast the sales of individual products. And this data, in turn, can also be made available to industry to control and optimise its own production. To do this, however, the individual components such as slip rings must be reliably integrated into the network.

The company-wide linking of industry & trade

So to achieve this goal, one thing above all is crucial: the company-wide linking of industry and trade. And also the internal linking of all departments involved. Only in this way, for example, can incoming orders in the merchandise management system directly influence the production line.

Thus, the food industry also has a duty to adapt the process through which products are sold, produced and packaged. The entire value chain, from the fishing port on the North Sea to the packaged product on the supermarket shelf, must be connected via a common system to exchange data. Thus, in the future, various production plants will not only have to transmit fluids, signals and electricity via slip rings and rotary unions, but above all data. And in significantly higher rates than the 100 Mbit/s that are common today.. And zero waste is not the only goal that can thus be achieved more easily.

The following figures also show that this is urgently needed. In the last eight years, the number of Food recalls more than doubled, primarily due to microbiological contamination and foreign bodies. However, this is not because the quality of the products is declining, but because manufacturers have become more sensitive and can react more quickly with the help of big data. But the DLG-Trend Monitor from 2018 shows that 65% of the 140 companies surveyed at the time attribute a large share of necessary investments to food safety, but only 15% to digitalisation. Both go hand in hand. Self-optimising processes and condition monitoring in particular play a decisive role. For this, however, the data already collected today must also be evaluated and used. However, in many companies, approx. 97 % of data collected e.g. by field devices not used at all, primarily due to a lack of connectivity. Slip rings with high data transmission rates and hybrid rotary unions can make a decisive contribution here.

Slip rings Hotspots

Hybrid Glass fibre slip rings for the transmission of analogue or digital optical signals with Data rates up to 10 GBit. Singlemode or multimode fibres for single or multi-channel transmission. Customised and combined power and signal versions possible.

Smart Factory

The optimisation of resource management and flexibility is crucial. Production facilities such as filling plants independently provide information on the status of the system and the process parameters. The plants use this data to monitor themselves and intervene in processes in a corrective manner. They therefore assess themselves what their task is at the moment and whether any capacities are free.

They also transmit these free capacities to a smart data management system that connects purchasing, sales, logistics and production. Here, the capacities are compared with incoming orders. If the demand side reports demand, production can respond flexibly. The demand side can also access a large database of historical sales figures and hundreds of other factors, so that trend changes can be recorded in real time and production can be adjusted just as quickly. In the future, data sources will also include linked weather simulation systems or smart refrigerators, which also provide crucial information for accurate demand forecasts. This not only minimises downtime, but also reduces the use of resources and energy. This has a positive impact on company figures and goals such as zero waste.

Self-optimising processes & condition monitoring

There is another advantage when plants can exchange not only fluids and power but also data with the help of smart systems and hybrid slip rings and rotary unions. With the help of data mining and machine learning, production processes can optimise themselves, perhaps even completely without human intervention in the future. The concept Condition Monitoring, which was designed within the framework of Industry 4.0, is the basic building block here. This can sometimes also reduce product recalls due to microbiological contamination.

For example, the control of a KZE (flash pasteuriser) for beverages can be optimised with the help of so-called cyber-physical systems. For this purpose, production processes and plants such as a flash pasteuriser are digitally simulated and linked to real plants by means of abstraction layers. In this way, the heating process, which nowadays costs more time and energy than it should, can be optimised on the basis of data. For this purpose, a heated product is characterised during production before and after heating (for example, based on its microbiological composition). At the same time, the holding temperature and time are recorded. A comparison of collected data and their simulation in the cyber-physical system then makes it possible to find the optimal ratio between microbiological safety and thermal load and to adapt it individually to the respective product in the real plant.

Another important area of the food and beverage industry are systems for Mass flow. By default, data such as density and concentration of the medium are recorded here. However, there are also masses of key figures that are recorded but not used or evaluated, for example the Vibration frequency or the Excitation current. And these are just two of more than 700 other parameters that sensors can record in flow systems. The evaluation of such data could reduce downtimes enormously because, for example, gas bubbles forming in the medium or deposits in the channels of the rotating union can be detected at an early stage. Smart sensors could thus predict unexpected foam formation. Condition monitoring thus enables continuous verification without interrupting the production process. In the field of baby food production, such data can also help to trigger processes that are necessary for accurate dosing of recipe ingredients to ensure product safety.

Tank cleaning with video surveillance and rotating cleaning equipment

Another interesting area related to bottling plants or breweries: The Tank cleaning. If data is not only collected but also transmitted quickly and without loss, e.g. through appropriate slip rings, industrial companies can identify process problems in good time. Tank cleaning, for example, represents one such problem. Much too large and resource-intensive cleaning systems, which are always geared to the maximum possible degree of contamination, clean the entire tank at maximum capacity. For optimal cleaning monitoring, not only the process but also the success of the cleaning must be documented. Here, for example, the Video signal transmission important, which is associated with HD-SDI Slip rings can be realised. Thus, an optical sensor for contamination and a Rotatable cleaning device with self-learning process control ensure that heavily soiled areas of the tank (usually the filling level rim and nozzles) are cleaned with more power than less dirt-exposed areas. This saves energy, time and cleaning agents. A hybrid rotary union could also transmit not only the water and detergent here, but electricity, signals and data at the same time.

Hybrid pneumatic/liquid + electric

Classic use of slip rings in the food industry

We at rotarX have a passion for slip rings and have more than 25 years of experience. We pride ourselves on our ability to remain innovative and adapt to the demands of the market. We work with our customers to find the best solution for their project and offer a variety of customisable solutions.

Bottle washing and cleaning systems

Bottle washing procedures are mandatory in the food and beverage industry to maintain a safe environment. There are a number of different systems that can be used, but typically bottle washers use air, water or liquids to wash and sanitise the bottles prior to packaging. In addition, there are a variety of machines, including those that invert the bottles to use gravity and air to clean the containers. Some machines also spray water or detergent into the bottles, and the slip rings used must withstand exposure to water and chemicals.

Rotating filling systems

After the bottles have been thoroughly cleaned, they can be filled. There are a variety of systems a manufacturer can choose from, but one commonly used solution is the rotary filler. Common types include pressure fillers, gravity fillers, carbonated beverage fillers and canning machines. All of these systems use slip rings to transfer data from one component to another and ensure the continuous movement of the machine.

Bottle closure systems

When the bottle fills up, it must be sealed to maintain freshness and ensure safety during transport. Automatic capping machines are the most consistent compared to other machines. Consistency is important to ensure that all bottles are properly capped and retain their freshness when they reach the end consumer. In automatic capping machines, caps are fed using cap lifters to ensure they are positioned correctly for all bottles that pass through the machine. This ensures high accuracy and speed when filling a large number of bottles.

Enclosed slip rings

Our encapsulated slip rings are a versatile solution for use in machines on the factory floor. The encapsulated slip ring consists of a rotating and a stationary part. A series of contact rings are mounted on the rotor, which are seeded together. This and the encapsulated housing protect the slip ring from dust and moisture, which extends its service life and reduces maintenance. This slip ring solution is available in various sizes and also in a mini version for applications with limited space.

Slip rings for automation

Automation slip rings can be used for more complex tasks in industrial power and signal transmission. Depending on customer requirements, we offer two different qualities of automation slip rings: Standard and industrial quality. Inside the enclosure, two to 108 rings can be processed for power and signal transmission. Ethernet, USB, RS, CANbus, video signals and sensor signals are just some of the possible transmissions offered by this slip ring. With an aluminium housing, this slip ring features low electrical noise, low contact pressure and a long service life.

Separate Slip Rings

Slip rings without housing consist of two parts: the rotor and the brush holder. The two parts of the slip ring are separated, which offers greater flexibility when mounting in the customer’s machine. This allows the customer to freely choose the position of the rotor unit and place the brush in the most suitable position to the rotor unit. This slip ring has no housing, which means that the customer must ensure that each component is protected from dust and water. We offer a range of configurations for this slip ring solution and are happy to help you find the best solution for your needs.

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Practical slip ring solutions for your application

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.