Slip ring assemblies and rotary unions - transmission of power, signals & data

slip rings and rotary unions (also slip ring bodies or slip ring transmitters) are important electromechanical components for commercial and industrial machines in various fields of application. From crane technology to filling systems, packaging machines and medical technology. As a manufacturer and thanks to our competent engineers, we at RotarX know exactly what slip ring bodies must be able to do in your industry in order to guarantee technical functions, efficient automation and at the same time business success. But why do you actually need slip rings and rotary unions?

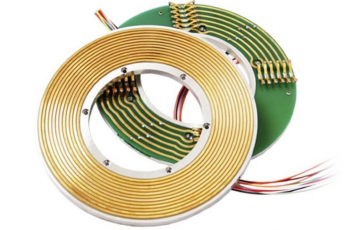

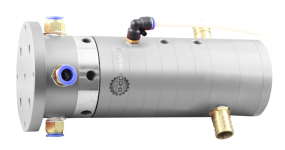

rotating components of various systems and machines often prevent the transmission of electrical power, data or signals via cables, i.e. a fixed power supply and data transmission. The so-called slip contact a slip ring body, optionally a fiber brush or fiber brush, and our reliable technology allow a wireless power and signal transmission between stationary and rotating components. Or between two components rotating differently or against each other. Slip rings are the only way to enable reliable, maintenance-free and low-wear power transmission, signal transmission and data transmission with simultaneous high system availability . Slip ring transmitters or rotary unions are also used for the wireless transmissionof liquid media (fluids) such as oil, water, grease and emulsion. The transmission of compressed air and gases can also be made possible by means of corresponding rotary unions.

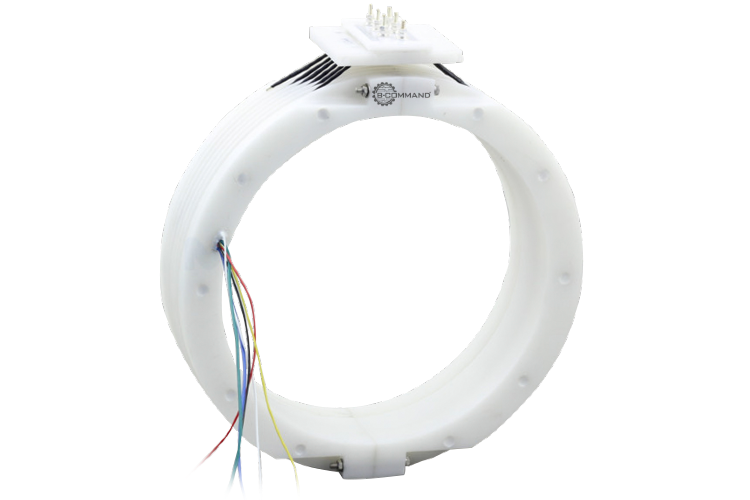

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Wide range of applications for slip rings

Applications for rotating unions

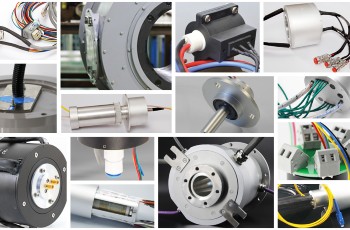

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

The fast and reliable data transmission by slip ring bodies, e.g. of measurement data or video signals via additional optical channels, is becoming increasingly important, especially in connection with the industry 4.0. This is because here even the smallest and previously purely functional rotating components no longer have to guarantee not only power transmission but also data transmission, on which modern plant control systems are increasingly based. For this purpose rotary connectors are used as slip ring rotary joints. In addition to electrical power, they also transmit optical fibers, signals and field buses such as 100 BaseT Ethernet to the inside of rotating systems.

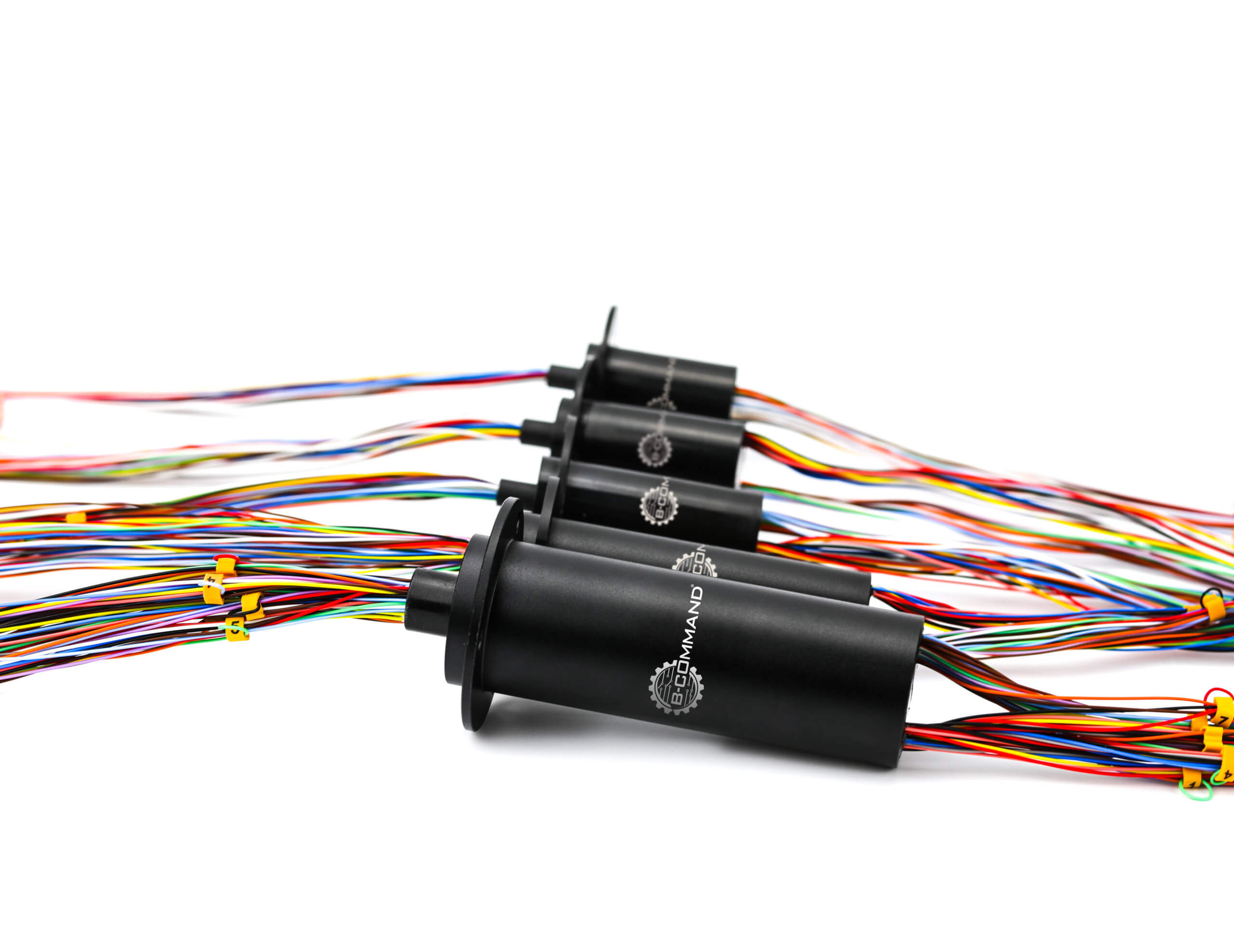

In addition, these rotary transmitters or rotary connectors, so-called hybrid slip rings, are also required for the rotary transmission of liquids, gases and compressed air, e.g. hydraulic fluid in the industrial and wind power sectors. These are also referred to as pneumatic slip rings.

Slip rings from rotarX for:

- electrical power transmission

- rotary transmission of fluids, compressed air & gases

- Signal transmission / data transmission (KOAX, HD-SDI, USB, fibre optics, Ethernet, field buses)

function & quality of the slip rings from rotarX

Als manufacturer of various slip ring bodies, rotarX elies on a combination of targeted design processes, a selection of the best raw materials, professional production conditions, 100% quality control and professional assembly at the customer’s site. In addition to a large selection of various slip rings for a wide range of applications, which are available to you in a kind of modular system, we are also available to you on site as a competent partner. Our products convince by high performance, wear resistance and high material quality of the contacts, which leads to high plant availability, flexibility and an economic price/performance ratio. A special focus is also placed on minimum friction and the lowest possible maintenance intensity. Only in this way can slip rings be used effectively and efficiently in industrial applications such as packaging machines, robotics or automation. Apart from the basic requirements for slip rings, the demands vary greatly depending on the operating conditions. For this reason, we offer modular slip ring systems that can be completely individually adapted to your needs. For example, our slip ring bodies are convincing even under rough environmental conditions and temperatures. Even strong vibrations or corrosive and salty air, e.g. when used in offshore wind turbines, do not affect our products.