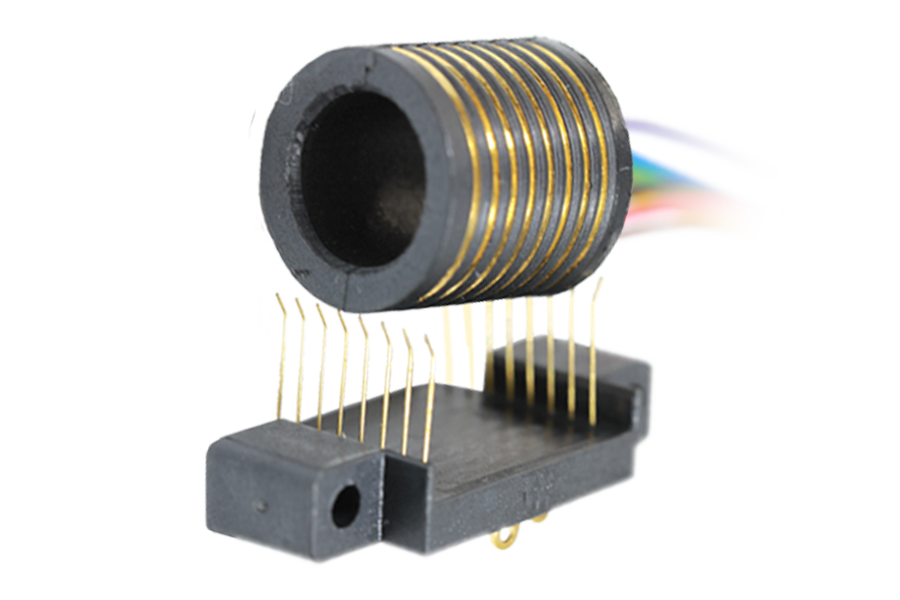

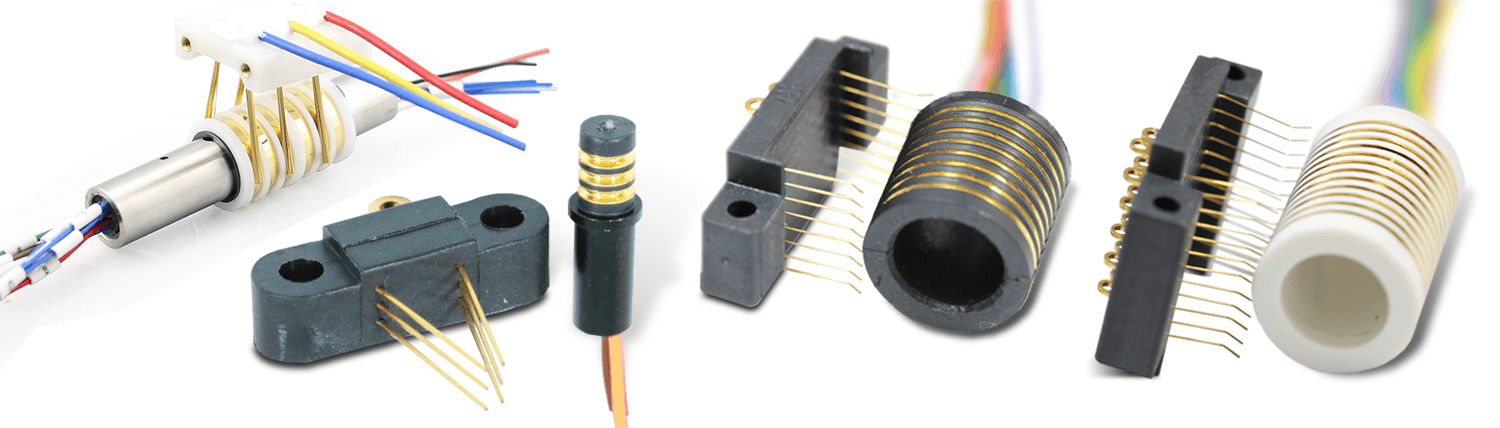

Separate slip rings & brushes without housing

Separate slip rings for easy and quick installation

Technical data

Electrical Specifications

- Number of rings: 3-15

- Nominal current: 2-10A per ring

- Max. Working voltage: 240/440 VAC/DC

- Voltage withstand: 500V @50Hz

- Electrical noise: max 10mΩ

- Isolation resistance:

1000 MΩ @ 500 VDC

Seperate Slip Rings

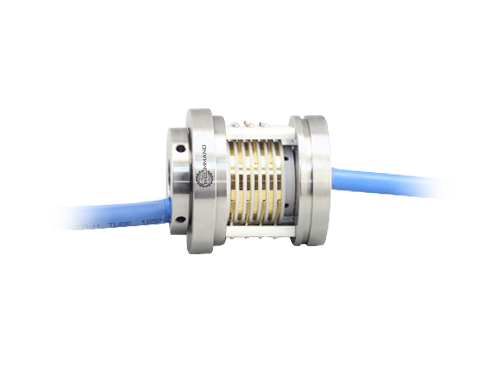

Maximum installation freedom with houseless slip rings. Other designations are also split slip ring or PCB design slip ring. Open or housing-less slip rings consist only of the current-carrying components. By omitting the housing, they ensure maximum flexibility and freedom during installation. The slip rings are manufactured in standard dimensions. This makes the use of industry-standard housings and hollow shafts particularly easy. On request, the manufacturer can offer its support in the selection of suitable housing-slip ring combinations.

Slip rings without housing

Properties of houseless slip rings

By their very nature, enclosureless slip rings are extremely sensitive to contamination of all kinds. Furthermore, they are not shielded. The resulting interference currents are emitted unfiltered into the environment. Enclosure and interference suppression are therefore the responsibility of the customer. We recommend the use of enclosed slip rings only if the appropriate know-how is available for their use. As an alternative, we can offer slip rings with housing, which have extensive active and passive protection.

Use of houseless slip rings

Enclosureless slip rings are used wherever a sustainable enclosure is already available on site. They are just as popular as an addition to complex electronic circuits as they are for installation in hollow shafts. Where many sensitive components are already combined into an open assembly, slip rings can be easily installed without enclosures. These components do not pose any greater active or passive hazard than any other electronic component. By eliminating the housing, these slip rings save weight, costs and installation space. This makes their use very flexible.

Functionality of slip rings without housing

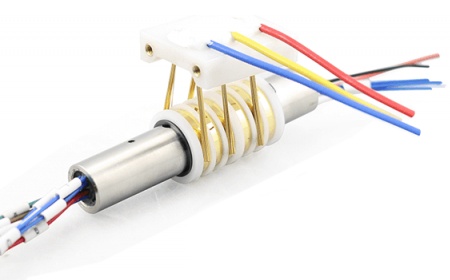

Enclosureless slip rings consist of a rotatable rotor and a fixed stator. The stator sits outside the rotor. It consists of a series of brush contacts. The slip ring has a suitable number of rings. As a rule, each brush contact is double. This increases the transmission reliability. Since this type of slip ring is particularly exposed to the environment, only gold-plated copper is used as the contact material. Gold is extremely resistant to oxidation and most acids and alkalis. Regardless of whether moisture penetrates or an acidic atmosphere surrounds the slip ring, transmission remains guaranteed in any case.

The brush contacts are designed as long “legs”. This filigree design limits the speed of the houseless slip rings to a maximum of 400 revolutions per minute. Nevertheless, they have a service life of approx. 400 million revolutions. With permanent rotation at maximum speed, this corresponds to a service life of just under 2 years.

Enclosureless slip rings have the following advantages:

- Extremely space-saving

- Extremely low weight

- Easily integrated into existing, open systems

- Made to standard dimensions

- Easy to replace

- Repairable within narrow limits

- Corrosion-resistant contacts

- Minimal wear

By eliminating the housing, the components of these slip rings are limited to what is necessary. This makes them very light and extremely flexible in installation. The open design makes all components accessible. In contrast to many enclosed slip rings, easy maintenance work can be carried out on enclosed slip rings: cleaning or light adjustment of brush contacts is particularly easy with these components. Due to the high-quality design and the use of precious metals as contact material, the enclosed slip rings are very durable. Like all slip rings, these components allow continuous rotation through 360°.

Slip rings without housing: Use

Split slip rings are mainly used in hollow shafts. They make optimum use of the available installation space. The hollow shaft thus practically forms the housing of the open slip ring. The contacts of the rotatable inner rotor can be conveniently guided through the hollow shaft to the outside. As an alternative to hollow shafts, they can also be used in open assemblies that are fully enclosed. Typical applications are thus as follows:

- Actuator motors in hydraulic or pneumatic control systems

- Three-phase motors with internal speed monitoring

- Rotary switches on control cabinets

- Extremely space-saving drive and control combinations for drones and models

Drone construction in particular has increased the need for open slip rings. With these components, comprehensive, two-way signal transmission is ensured: Power supply to the rotor motors, acquisition of control signals for camera and gimbal (camera positioning), monitoring of rotational speed and other parameters, are typical signal types in these devices.

With this dynamic and innovative technology, slip rings without housings ensure maximum transmission reliability with a minimum of weight, space requirements and costs.

Technical data

Open slip rings are available in a selection of 3-15 rings. Each ring can pass a rated current of 2-10 amps. The maximum working voltage is 240 volts for alternating current and 440 volts for direct current. Of course, weaker currents are always possible.

However, the maximum dielectric strength is only 500 volts, which is only slightly higher than the highest permissible DC voltage. Comprehensive electrical protection and precise planning are therefore indispensable for these sensitive components. Unencapsulated, the houseless slip rings emit a maximum noise of 10 mΩ. The insulation resistance is 1000 MΩ at 500 volts DC. The rotational speed is limited to a maximum of 400 revolutions per minute. The cable length is freely definable. Incoming and outgoing cables are identically coloured or patterned. This eliminates the possibility of confusion. The temperature tolerance is between -30 °C and +80 °C. A service life of 400 million revolutions is specified for all houseless slip rings.

PCB Design Slip Ring Cleaning and Maintenance

The open design of the houseless slip rings enables easy maintenance. The corrosion-free contact material of the ring and abrasive brush is particularly easy to clean. We recommend soapy water and demineralised water for rinsing. This will also remove any limescale deposits that may be present. After cleaning, it is best to dry the slip ring with warm air. Slightly bent abrasive brushes can be re-bent. However, the maintenance possibilities are very limited due to the filigree construction of the components. Except in specific cases of need, for example after flood damage, no inspection and maintenance of houseless slip rings is necessary. As a precaution, we recommend not attempting maintenance and simply replacing the low-cost component if necessary.

How to find the optimal houseless slip rings

Enclosureless slip rings are ideal components for serial assembly. Nevertheless, we supply you from quantity 1 and in any configuration. If you have not found the right open slip ring in our range, please call us.

Customer requests and special designs are always possible. Trust us and our experience from many years of designing, manufacturing and trading slip rings. Together with you, we will find the optimum slip ring for your applications. In addition to houseless slip rings, we also offer you a comprehensive selection of all other slip ring types. Take a look at our product variety and be inspired by our offer.

We are your contact when it comes to quality slip rings of all kinds.

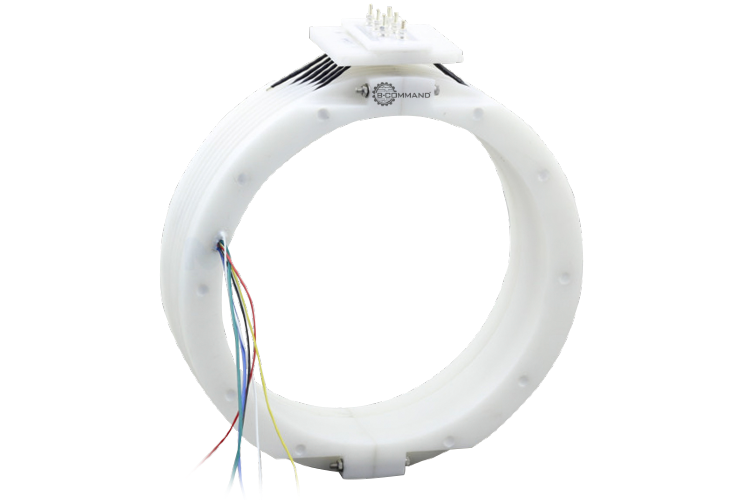

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.