Slip rings for high rotational speed and industrial automation

Compact Slip rings with rotational speeds of up to 1000 rpm

Technical Specifications

Electrical specifications

- number of rings: 2-125

- rated current: 5-10A per ring

- Max. working voltage: 440/690 VAC/DC

- Potential strength: ≥500V @50Hz

- electrical noise: max 10mΩ

- Insulation resistance: 1000 MΩ @ 500 VDC

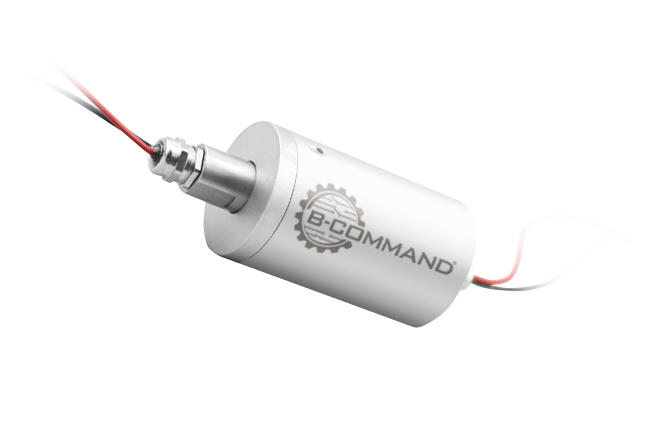

Reliable power and signal transmission through encapsulated miniature slip rings

Our automation slip rings can be used for more complex tasks in industrial power and signal transmission. Depending on the customer’s requirements, we offer two different qualities of automation slip rings: Standard and Industrial quality.

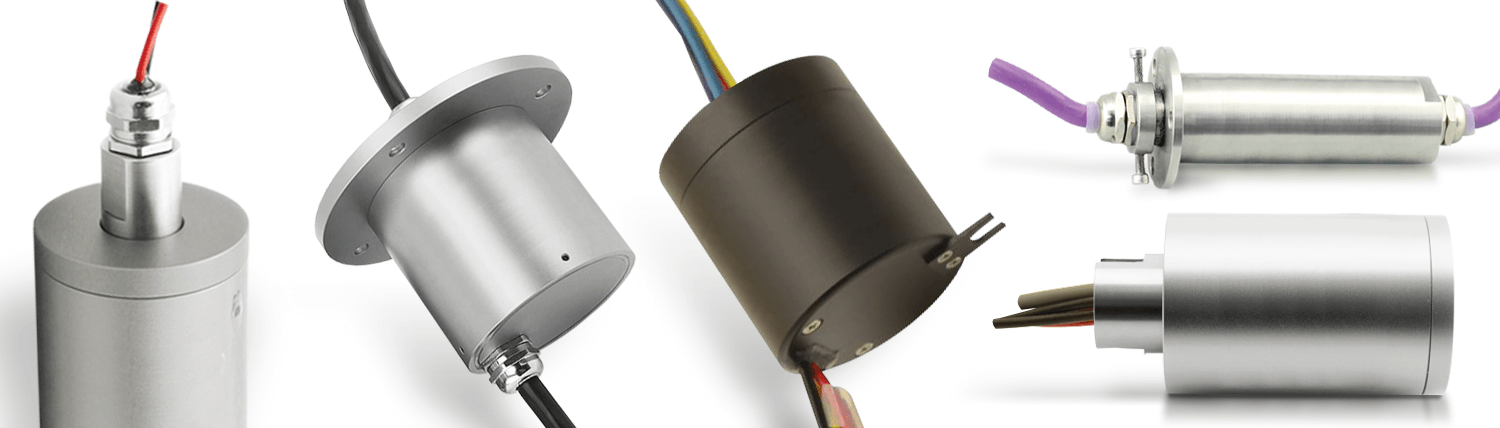

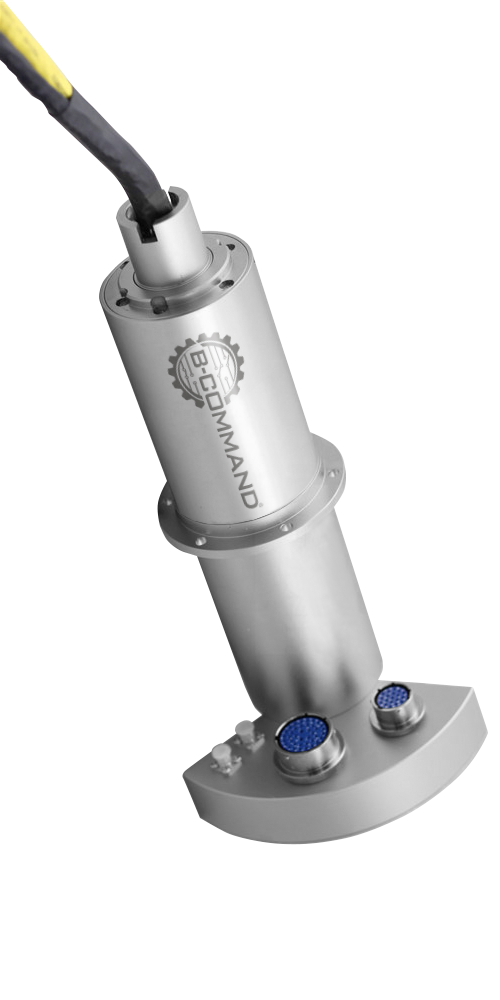

The automation slip rings are available in housing diameters of 56mm, 89mm and 119mm in versions with rotor and stator flange or without flange. Inside the housing, 2 to 108 rings can be processed for power and signal transmission (Ethernet, USB, RS, CANbus, video signals, sensor signals, etc.). The housing is made of aluminium. Inside the automation slip rings we use the most advanced fibre brush technology and silver-to-silver or gold-to-gold multi-contacting. The slip rings feature low electrical noise for high data rate field bus transmission, low contact pressure and long life. We offer standardised & modularised design and fully customisable products according to customers’ specific requirements in various applications. If you have special customised requirements, we will be happy to advise you to create the most suitable recommendation for your specification.

Automation Slip Rings

Automation Slip Rings

The task of Automation slip rings is the reliable transmission of signals and power in electrical form. The mechanical movement of the contact surfaces of brushes and rings towards each other with high quality transmission is the decisive challenge. Due to our technical design, electrical noise, which would be generated by sparking, is reduced to an absolute minimum. The electrical noise must be minimised for two reasons: firstly, the noise reduces the quality of the signal transmission and secondly, the noise generates an interference signal which, in the form of electromagnetic radiation, can have a detrimental effect on components in the vicinity of the slip ring body. In complex automation technology, mobile power transmission systems of inferior quality can therefore quickly affect process reliability. For this reason we have developed the series of our Automation slip rings for you. By means of a variety of integrated technologies we reduce potential disturbance variables to a minimum. In this way we protect your production equipment and contribute to efficient operational readiness.

Functionality of Automation slip rings

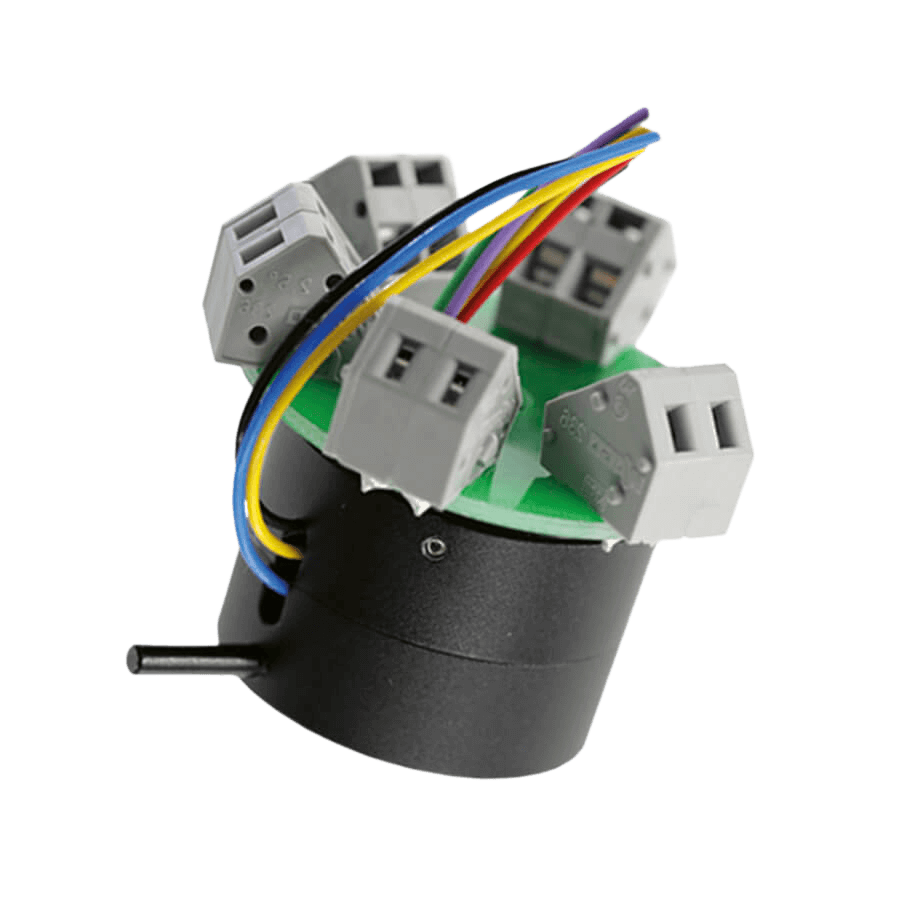

The structure of the Automation slip ring is designed so that each cable runs into the housing on one side and onto a brush, which in turn rests on a separately insulated ring. Another cable leads from the ring on the opposite side out of the housing. The Automation slip rings are particularly well prepared for their tasks due to two characteristics:

- Silver-silver or gold-gold contact surfaces

- Encapsulation through robust aluminium housing

The precious metal surfaces reduce the electrical resistance to a minimum. This leads to a very high quality signal transmission. Furthermore, the contact pressure of the reinforced and maintenance-free contact brushes is designed in such a way that metal abrasion occurs only minimally. This makes the Automation slip rings trouble-free and durable.

The Automation slip rings are completely encapsulated by an aluminium housing. The use of the light metal has numerous advantages. The construction can be robust and can withstand environmental influences and vibrations. Electromagnetic interference from outside is safely shielded, which has a positive effect on the signal quality. The housings are available with or without flange. The flanged version has drilled holes with which the module can be mounted. The version without flange is particularly space-saving.

Advantages of Automation slip rings

The standard version of the aluminium housing is designed for protection class IP51. This means that it provides complete protection against accidental contact and lasting encapsulation against dust penetration. Depending on requirements, Automation slip rings can be manufactured with different degrees of protection. Give us a call. Together we will clarify which protection class is best suited for your Automation slip rings. Automation slip rings offer you the following advantages:

- Shielding against interfering signals

- Impact-resistant housing

- acid-resistant housing material

- Corrosion-resistant enclosure

- Minimum internal wear and tear

- Very reliable signal transmission

- Long-life ball bearings

The use of a metallic housing is ideal for shielding any interfering signals and ensuring that the signals are transmitted unaffected.

From a protection class of IP51, this offers sufficient protection against moisture and penetrating dust. This reliably prevents the formation of insulating dust layers on the slip rings. The gold or silver contacts are largely insensitive to corrosion. However, since contamination of the contact surfaces always has a negative effect on the transmission quality, a suitable protection class is selected depending on the application. Even in the simplest version, Automation slip rings provide reliable protection against these interference variables.

The housing is made of thick-walled aluminium. Vibrations and slight knocks hardly affect it. The housing is sufficiently thick-walled to allow light machining, such as engraving. Aluminium is corrosion-resistant and resistant to most acids and alkalis.

The slip ring technology enables reliable, continuous 360° rotation even at high rotation speeds. This makes the Automation slip rings for particularly demanding applications, in various applications without any problems

Variants of the Automation slip rings

We offer automation slip rings from two to 125 contacts. Each ring can transmit a rated current of up to 10 amperes. With an operating voltage of 440 Volt AC or 690 Volt DC, these high performance slip rings enable very demanding applications. A residual electrical noise is limited to 10 milliohm. The slip rings allow a maximum rotational speed of 1000 revolutions per minute. They can be used between -30 °C and +80 °C without any problems. Please contact us. We will always find the optimum solution for your slip ring.

Installation of the Automation slip rings

Easy handling is always an important goal for us when developing our products. Despite their high performance and internal complexity, our slip rings can be integrated into assemblies like normal components. The flanged version is recommended for installation in housings or on panels. Chamfered holes are already integrated in the flange. The slip ring bodies without flange require a suitable guide or sleeve on site, which, however, enables deeper integration. The robust aluminium housings can be easily clamped or glued. A linear alignment of the slip ring body is important during assembly. This avoids eccentric movements, which can lead to mechanical stress on the ball bearing. The incoming and outgoing cables are always clearly marked. Mix-ups in the electrical installation are therefore impossible.

Use of Automation slip rings

The Automation slip rings can be integrated at various points in applications. Wherever an electrical contact is required over a 360° rotatable path, Automation slip rings are the ideal choice. This version can also be used for fast rotating applications. The slip rings allow rotations of up to 1000 revolutions per minute.

Maintenance of automation slip rings

The Automation slip rings are maintenance-free. They are not intended to be disassembled, as this would impair their dust and water tightness and their internal structure. Depending on the type, we give you a defined service life for each Automation slip ring. The easy-to-install housing can be replaced without any complications in the event of replacement to ensure the long-term operation of your systems.

Your way to the optimum automation slip rings

If you are looking for high-quality, reliable Automation slip rings at an optimum price/performance ratio, then you have come to the right place. Give us a call or send us a message. Describe your challenge and we will find the ideal slip rings for your applications. We also manufacture customer-specific special solutions from batch size 1. Our slip rings perform their service reliably all over the world. Come to us if you are looking for Made-in-Germany quality also in inexpensive slip rings for automation.

Practical slip ring solutions for your application

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.

WE LOOK FORWARD TO YOUR MESSAGE

CONTACT

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.