Glass fibre slip rings for data transmission in modern wind turbines

Angle of attack of the rotor blades, azimuth position and speeds or standstill of rotor and generator must be precisely recorded and transmitted. However, not only within the wind turbine to the higher-level control systems, but also via the Internet, in order to enable the remote control and monitoring of the wind turbine seamlessly and around the clock. The data generated primarily by anemometers, incremental encoders in the drive train or rotor hub and absolute encoders of the pitch motors should therefore be best transmitted via Glass fibre slip rings be transferred. They enable a contactless, low-wear and reliable transmission of all this information in real time (Data rates of up to 10 gigabytes).

Namely Independent of media feed-through and power transmission through hybrid rotary joints. These are subject to wear, for example due to the friction of the brush on the slip ring. The reliability of the data transmission can thus also decrease over time. Similarly, current transmission can interfere with the combined transmission of data. At fibre-optic slip rings with optical fibres this risk is much lower.

Technical data

Electrical specifications

- Number of rings: 2-80

- Rated current: 5-10A per ring

- Max. Working voltage: 440VAC/DC

- Dielectric strength: ≥500V @50Hz

- electrical noise: max 10mΩ

- Insulation resistance:

≥1000 MΩ @ 500 VDC

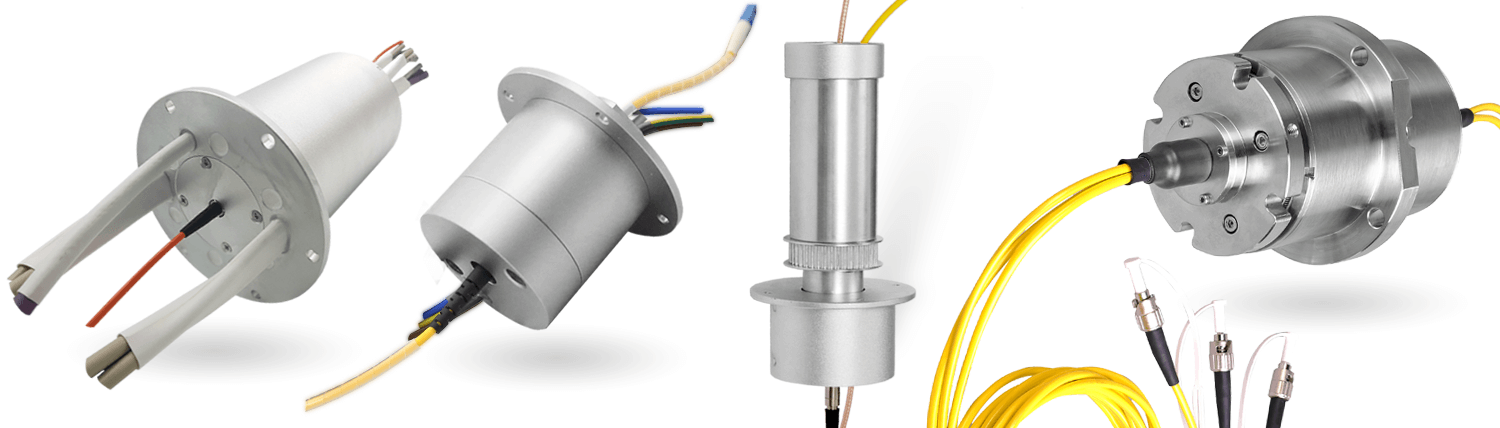

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Advanced Load Control for better efficiency and less wear and tear

The – literally – smooth transmission of position data, angles of attack and speeds via the internet is especially important for the Advanced Load Control, Pitch-Control and YAW-Control crucial, i.e. the dynamic control and positioning of the rotor blade position. The goal of Advanced Load Control is not only to distribute the load on the drive train as evenly as possible, but also to detect any fault conditions at an early stage in order to reduce wear, improve efficiency and prevent damage. This only works if the sensors (especially anemometers and encoders) as the basis of the intelligent control system provide correct values and the actuators perform their function just as reliably on the basis of these values. This is the only way to permanently increase the efficiency and safety of modern wind turbines. The Safety Integrity Level therefore also regulates requirements for individual components, especially the Protection against corrosion, wear and faults. Sensors should therefore also be able to carry out independent self-diagnosis, detect potential faults in advance and forward them to control and monitoring centres without delay. And since the transmission of power as well as signals and data in wind turbines is almost always between rotating (Rotor) and static components (Stator) (between the anemometer, generator, drive shaft, tower slewing ring, rotor hub and pitch motor), are Slip rings here indispensable for power, data and signal transmission.

Especially (but not only) with Offshore-Attachments is a reliable and Data-based monitoring of operation from a distance is crucial, as maintenance work is even more complex and has to be planned for longer. So if there is a failure or malfunction to water, efficiency or the complete power generation of the plant sometimes takes significantly longer. than for onshore wind turbines.

And not only the discussion about the 10H-Regulation in Bavaria makes it clear how important Offshore-Energy generation will continue to be in the future in order to master the energy transition with the help of wind power. In the meantime, a single offshore turbine produces as much energy as entire wind farms used to. But even on land, wind turbines are nowadays veritable data slingers, which can transmit data – sometimes kilometres away – to the – Monitoring and control centres have to be evaluated. That is why nowadays no longer just slip rings for power transmission or hybrid hydraulic-pneumatic-electrical systems require rotary unions, but slip rings in wind turbines also have to be More and more data and that ever faster. Modern glass fibre slip rings (Fibre optic rotary joints) with optical fibres is of particular importance here.

Offshore offers more power, but also more challenges

The first offshore wind farm in the world, the 1991 before Vindeby in Denmark was connected to the grid, produced approx. 0,45 Megawatt power. Germany’s first offshore wind farm (Alpha Ventus) only went 2009 to the grid and was at that time 5 Megawatt Turbines equipped. 2022 the first prototype of the most powerful wind turbine in the world. – MySE 16.0-242 aus China – be built, which is already 16 Megawatt power is generated. One turbine thus generates approx. 35 times more energy, than the entire first wind farm in the world. This wind turbine from the Chinese company MingYang Smart Energy is also specially designed for offshore use.

Because on water there is not only considerably more space available, but also the Wind speeds are higher and the wind comes more steadily than on land. Besides the Corrosion protection from salt water However, offshore turbines also have to master special challenges due to precisely these advantages. Above all, the control and monitoring of speeds, wind tracking and pitch angles must function reliably from a distance in order to be able to react to the more dynamic wind conditions. Because Time and costs for maintenance work – which are already not exactly easy on land – increase drastically again for offshore plants.

A reliable and low-wear Data transmission via fibre optics is crucial. And much of this important data is transmitted between stationary and rotating parts, for example from the Anemometer to the pitch motors to Power limitation, or to the Tower slewing ring (YAW-Control) to Wind tracking of the nacelle. Monitoring the drive train and generators is also important, especially at very high and low wind speeds, To prevent damage to the plant and the power generation from dropping to zero.. And whenever signals, energy and data need to be transmitted between the rotor and stator, there are Schleifringe erforderlich.

Frequent source of error: Incorrect data transmission for pitch control

Modern wind turbines have to meet ever higher requirements in terms of safety, efficiency and reliability. This also requires the transmission of increasingly larger amounts of data in ever shorter times. To the most important data for the gentle and at the same time efficient control and energy generation of a wind turbine include those of the anemometer, on which the pitch control of the individual rotor blades is based (flow speed, wind direction, humidity, temperature, dew point, etc.). The controlled pitch motors independently adjust the individual so-called “blades” so that the wind can best turn the rotor hub.

The pitch control is used to the leading edges of the rotor blades into the incoming flow turned. This is also called Flag position is the term used. This reduces the lift forces and the speed or power, which protects against damage to the drive train at high wind speeds and relieves the rotor. Likewise, the Pitch angle of 90 but also for use when Very light wind</strongblows and the turbine is not in operation because the rotor shaft cannot be driven. At the optimum wind speed (one speaks here of a speed between 2.5 metres and 12 metres per second) is the Pitch angle 0. This thus corresponds to the best working position for optimal power extraction of the wind energy by the rotor blades. If the pitch angle is increased, the power is reduced, which may be necessary at high wind speeds. From High wind speeds of 25 metres per second the pitch control is no longer helpful. Here, the system must switch off reliably so that the rotor shaft does not turn too fast.

Also the so-called YAW-Control (Yaw control / yaw control) of the tower rotation is based on data from the anemometer. It enables wind tracking of the entire nacelle of a wind turbine in order to continue generating energy even when the wind direction changes.

All this data is often used by Hybrid rotating unions for power, data, signals hydraulics and/or pneumatics in only one component transmitted. Within a wind turbine itself, this can also be sufficient. For example, a component can transmit generated energy, the passage of Hydraulic fluid for the pitch motors, and the Leakage oil recirculation and combine the transmission of fieldbuses, video and control signals or Ethernet.

Data transmission through slip rings with optical fibres

The problem: The components are subject to wear and tear and so, over time, the Data transmission unreliable become, which leads to Faulty pitch control or YAW control can lead to. This is because with normal slip rings, the brush rubs on the ring, which leads to wear. In addition, the data must be transmitted in real time and not only within the turbine itself, but also from the wind turbine to the control centre. Constantly, in ever greater quantities, precisely and without delay. Data transmission via copper cannot do this. That is why it makes sense to use the Realise data transmission of modern wind turbines independent of media transmission and other power and signal transmission. Also the fact that the demand regarding the SIL 4 Category compared to SIL 3 category (IEC 61508 or PL e to EN ISO 13849-1 / Machinery Directive 2006/42/EG) is increasing for wind turbines, Increases the relevance of glass fibre slip rings in the wind energy sector.

Fibre optic slip rings with optical fibres (so fibre optics) have their strength in passing important signals in areas where current-carrying conductors are a potential hazard. This is why the fibre optic slip ring is particularly popular in avionics and nautical applications. But they are also used where reliable and low-wear transmission is important. Because the Data transmission is contactless, without brush. Thus, fibreglass slip rings are far less subject to wear than electrical or hybrid rotary unions. They are also significantly lighter and smaller than slip rings made of copper. And every engineer and wind farm operator knows how Decisive weight and space savings for wind turbines is.

They reliably transmit data signals without absorbing disturbance variables or becoming a danger themselves due to obsolescence. Nevertheless, every rotarX fibre optic slip ring is permanently encapsulated. The housing complies with protection class IP51. Higher protection classes (to IP69) are on request available. The robust Aluminium housing makes the fibre optic transformer sufficiently insensitive to light impacts, corrosion or aggressive environments. This means that the slip ring can be used for many years under extreme conditions without hesitation.

Especially for use in the Offshore sector we also offer slip rings of the Corrosion protection class C4H, so that the slip rings are also insensitive to salt water. Components of the C4H category are tested in the salt spray test. 720 Hours continuous salty spray mist exposed. In addition, instead of aluminium Plastic or precious metal for the housing of the slip rings are used. They can therefore be specially tailored to rough and wet environments, which is particularly important for FORJs (Fibre optic rotary joints) within the framework of the Pitch-Regulation is important.

They are designed for a service life of at least 200.000.000 Million revolutions and up to 5 Billion aligned (at up to 1,000 rpm) and for temperature ranges from -30°C to +80°C suitable. The optical fibres are protected and both their length and the connectors can be flexibly varied according to customer requirements. You also choose between single-mode or multimode fibres for single or multi-channel transmission. Customised and combined Analogue and digital power and signal versions are of course possible.

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.