Rotary joints and unions for transmission of fluids like water, oil, hydraulic & pneumatic

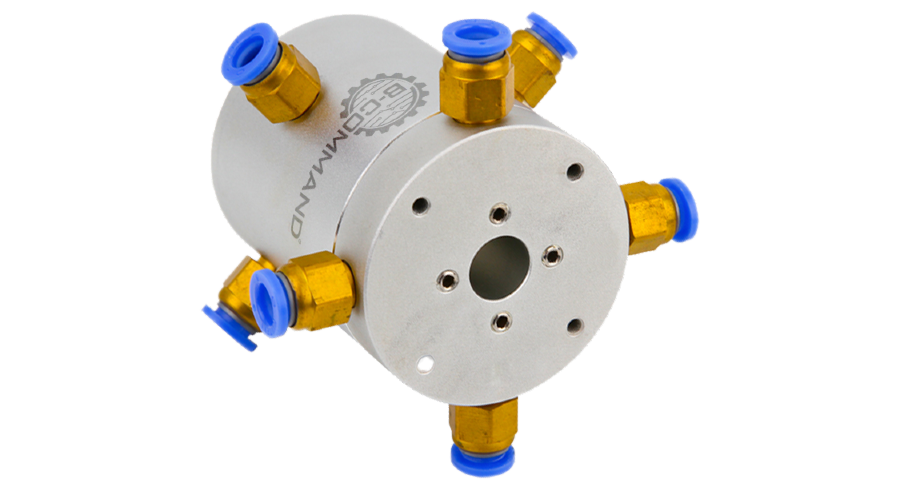

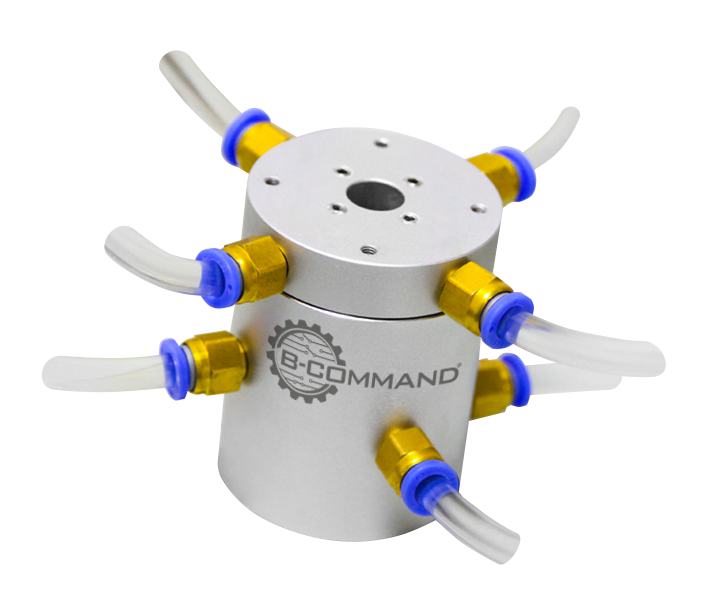

Customized rotating unions for hydraulic, pneumatic & fluids

Technical Characteristics

Specification Media Feedthrough

- Number of pneumatic/liquid feedthroughs: 1 – 24

- Connection sizes: M5, 1/8″, ¼”, 3/8″, ½”, 5/8″, 1″, 1¼”

- Connections straight or angled

- Pressure: up to 1300bar, 130MPa; 20000 psi, vacuum 0.01torr, 30HG

- Media: air, vacuum, hydraulic oil, water, hydrogen, nitrogen, steam, cooling water, hot water, acids, bases

Rotating unions for hydraulics, pneumatics & fluids

Unlike electrical slip rings, classic rotary joints do not have the task of transmitting electrical signals, power and data between stationary and rotating components. Instead, they enable the sealed transition of a fluid, or gases and compressed air between stationary supply lines and/or rotating components (against each other), such as rollers, spindles or motors So, they are often used for pneumatic and hydraulic energy applications as well as for the transmission of any liquid like:

- water

- emulsion

- hydraulic oil

- cleaning agents

- grease

- alkalis

- acids

- lubricants

- coolants

- oil

But our extensive range of customized rotating unions also withstand gas pressure, air pressure, vacuum and hydraulic pressure.

Why slip rings and rotary unions are so important

That is why electromechanical slip rings and rotary unions still have something in common: they are the foundation of almost every industry, whether food production, medical technology and pharmaceuticals, chemical industry, agriculture, robotics or the paper industry.

At the same time, they are also often an important component in various vehicles such as chain excavators, cranes or agricultural vehicles. For example, rotary unions can be used for tire pressure control systems on large agricultural machines to transfer the compressed air. In large hydraulic chain excavators, they carry hydraulic fluid and return oil.

That’s why it always made sense to combine the function of rotary unions and slip rings. For example, with just one component, the pneumatic energy for the tire pressure could be transmitted to the tire and the data from the measured values in each individual tire could be transmitted back to the driver’s cab. Or, for example, not only direct the return oil to the appropriate container, but also transmit the filling level of the hydraulic oil container. That’s the purpose of hybrid pneumatic, hydraulic and electrical rotary unions. They allow a combined transmission of data, power, electrical signals, pressure, gas, air, fluids and more.

And this is very important for several myriad applications where space is always at a premium. From the powertrain of a wind turbine to military vehicles, to satellites and rockets. Saving space and weight is extremely important, but at the same time reliability and durability must not suffer.

How do rotary joints work?

Depending on the area of application, multi-channel or single-channel rotary unions are used. Single-flow rotary feeders are used almost exclusively in the private sector, e.g., in swiveling water taps or in lawn sprinklers. Water only must be fed into a moving or rotating component, but not back.

In industry it is more complex. Hydraulic oil can be fed back and forth under high pressure by multi-channel rotary joints. Or they carry hot steam, for example in the paper industry, where rotating unions with siphons are used. Hot steam is introduced, condenses and is “pressed out” again via a siphon to heat the large dryer rollers. Rotary joints are also required for the pneumatics of a tire pressure control system. In this way, the tire pressure of the agricultural vehicle or the construction site vehicle can be adjusted to the ground while driving.

Rotary joints are essential for the performance of machines and vehicles in which they are installed. The configuration especially for critical environments requires theoretical and hands-on knowledge with a variety of applications. That’s what rotarX delivers.

Rotary joint

Application areas for Rotary Joints

Rotating unions are needed in almost all industrial sectors, from the food industry to onshore and offshore wind turbines and construction vehicles such as excavators. Therefore, they must meet a wide variety of requirements. Depending on what is to be carried out, rotating unions must fulfil different criteria, from the seal to the IP protection class, to the material, vibration, acceleration or operating temperature.

A classic rotary joint for fluids like water is therefore not automatically also suitable for media routing in the context of acids, lubricants, emulsion, hydraulics and pneumatics, since the latter must withstand much more hydraulic or pneumatic pressure (bar) or corrosion, for example.

This does not apply to our rotary unions. They combine the media feed-through for different types of fluids, compressed air and gases and can also be used as a pneumatic and hydraulic rotary union that can withstand high pressure.

These are just a few of the many criteria that must be met to perfectly integrate rotating unions into each individual area of requirement. Together with our experts, we will find the optimum solution for every area. Or you can simply configure your individual slip ring online.

Practical slip ring solutions for your application

A classic rotary joint for fluids like water is therefore not automatically also suitable for media routing in the context of acids, lubricants, emulsion, hydraulics and pneumatics, since the latter must withstand much more hydraulic or pneumatic pressure (bar) or corrosion, for example.

This does not apply to our rotary unions. They combine the media feed-through for different types of fluids, compressed air and gases and can also be used as a pneumatic and hydraulic rotary union that can withstand high pressure.

These are just a few of the many criteria that must be met to perfectly integrate rotating unions into each individual area of requirement. Together with our experts, you will find the optimum solution for every area. Or you can simply configure your individual slip ring or rotary joint online.

The seal makes the difference

The primary goal of our technology and individual advice: High availability, simple to install and repair, low maintenance and yet a long service life. And achieving these goals for pneumatic rotary unions, including normal media feed-through, or combined electrical rotary unions is significantly more demanding than for purely electrical slip rings or simple rotary unions. Not least because of the seal and the wear and tear caused by friction. The greatest design challenges are the clear separation of all media-carrying lines and the wear of the seals. The rotation of the inner and outer casing creates constant friction. In the case of purely electronic slip rings, this is less of a problem. However, where absolute tightness is important, rubbing rubber rings on plastic or aluminum are a limiting factor for the service life of the component. But we have already been able to master these and other challenges for a wide variety of industrial sectors.

The principle behind it: The balanced mechanical seal. In the case of pneumatic or hydraulic rotary unions, for example, this means that it is not the pressure but only the setting and restoring forces that act on the seal, which significantly increases the service life. On request, we also offer various pairs of sliding rings, such as ceramic, graphite or silicon carbide, to be able to react optimally to individual requirements and thus reduce the maintenance effort and seal friction.

Differences between classic and hybrid electric rotary joints

Since modern industrial and agricultural operations often require a combined rotary union for pneumatic, hydraulic and fluids, more and more customers are opting for hybrid rotary unions. The media tours are then not exclusive. Hybrid pneumatic rotary feedthroughs can therefore pass both liquid and compressed gas. And different types of fluids like acids, emulsion and water. But therefore, every channel and sealing needs different material.

That allows very interesting combinations. In addition to the transmission of pneumatic or hydraulic energy, gas, compressed air and vacuum, they can also be used to convey auxiliary and operating materials, such as coolants, cleaning agents or lubricants and hydraulic fluid. They can withstand up to 1300 bar at 300 revolutions per minute.

This means that media supplies, which could previously only be carried out at standstill or at low speed, are now also possible at high speed. The degree of automation and the productivity of the entire system are noticeably increased. In addition, they can be used from -30 °C to + 80 °C (other temperature ranges on request). Up to 24 channels for different media are available for the multi-way rotary unions – from water to pneumatics and gases. All combined in only one rotary union.

The application possibilities are thus practically unlimited. However, these powerful rotating unions are particularly popular with construction vehicles. Especially wheeled and tracked excavators with a rotating superstructure and hydraulic propulsion have at least one hydroelectric feedthrough in the undercarriage. This allows the engine and hydraulic unit to be conveniently accommodated in the rotating superstructure and still reliably supply the rotating motors of the undercarriage with hydraulic pressure. Multi-channel rotary unions also allow return oil and leakage oil to flow back into the hydraulic oil reservoir in the superstructure.

Our electric pneumatic and hydraulic liquid rotary unions offer even greater combination possibilities. These not only combine different type of media feed-throughs with the transmission of pneumatic and hydraulic energy, but can also transmit data, electrical signals and power. So basically, they also include the slip ring.

One conceivable area of application is in wind turbines, for example, primarily for pitch control. The electrical rotary unions can be used here for the hydraulic control for the blade angle adjustment of the rotor blades to adapt them to the wind speed. To do this, they must simultaneously transmit the sensor data of the control system or the anemometer, luminous flux and hydraulic pressure and hydraulic fluid, as well as corresponding auxiliary materials if necessary, and return used fluids like oil. This is the only way to optimally turn the blades of the rotor into the wind and to realize the power limitation at high wind speeds to avoid damage to the drive train. In addition, this approach saves space, as an electrical slip ring thus does not have to be installed as a separate component but is already integrated in the rotary union.

Your way to an individual rotary Joint

The basic prerequisite for the optimal solution is a detailed consultation. Together we define the framework conditions, including the determination of the required media and operating data. We need information from you on detailed process sequences, e.g. when which medium is pressurised, temperature influences, space conditions, but also the range of necessary channels, which must be variable depending on the user, for example at permanently installed work tables (with milling machines or other tools). In this case, a central interface for media and current feed-through is required according to a modular design.

Hybrid rotary unions are very popular

In the context of Industry 4.0, automation and digitalization, these combinations are becoming more and more popular, as in addition to fluids, gases or compressed air, more and more measured values and control signals also need to be transmitted.

An example of this is a so-called milking carousel or rotary milking parlour. Compared to the classic herringbone milking parlour, a rotating milking carousel enables almost completely automated milking of the dairy cattle. However, this requires not only the milk to be conveyed through a classic rotary joint, but also the transmission of measured values, data, power and, of course, electrical signals for automation and control.

Another application of these particularly powerful slip rings is in wind turbines. Here they are mainly used for hydraulic control of the rotor blade adjustment. They can transmit sensor data or luminous flux simultaneously with a hydraulic pressure that turns the rotor blades optimally into the wind.

Other application examples for hybrid multiway rotary unions:

- Workpiece and tool detection

- Clamping and releasing

- Cooling (e.g. spindle cooling)

- Plant inspection

- Turning and milling (also in combination)

Why RotarX?

For the special challenge of designing hybrid rotating unions, our many years of experience pay off. Our modular principle and individual advice from our experts based on your process parameters and environmental requirements enable over 50,000 different combination options.

Compared to a pure power or fluid feedthrough, the feedthrough of gas pressure or hydraulic pressure through a rotating union is an enormous challenge. A complex duct system is created between the rotor and the stator for the passage of the media. In addition, a central media line ends in a rotating coupling. The weak point in this design is the sealing. However, by using high-quality sealing rubbers and sophisticated engineering, these lines can withstand up to 1300 bar – and that at 300 revolutions per minute. This is made possible by the combination of different sealing technologies. Whether it is the mechanical seal, the hydrostatic seal or the elastomer or “plastomer seal”. This enables us to react explicitly to the requirements of media, operating and process parameters of our customers. The most suitable sealing technology is used for each media channel. In special cases, all seals can also be combined in one housing if required.

Multi-channel rotary joints for machine tools

Early on, more than just one medium had to be introduced, carried out or passed through a rotating machine tool part on corresponding workbenches. Sophisticated multi-flow hybrid rotary feedthroughs not only make simultaneous turning and milling possible, but also system control or cleaning of the table or machine parts, e.g. with compressed air. This is done via just one central interface, which the individual channel assignment, depending on the needs of the person currently working at the table, has no influence on. This allows the company to react flexibly to a change in channel occupancy at any time.

Multi-channel rotary unions are available for all conceivable variants, whether hydraulic, pneumatic, vacuum or a fluid feedthrough, e.g., coolant is required.

The increased demand for hybrid rotary unions arose from machining processes to ensure the central supply of compressed air or hydraulic fluid. Initially, there were advantages here, above all for chippers or for clamping and loosening workpieces, such as higher productivity and the possibility of combining a wide variety of functions with rotation. For example, supplying the workpiece spindle with media when turning, or with combined milling and turning work, in which rotary feedthroughs, for example, supply workpiece clamps with media. The hybrid supply of the tool spindle with cooling lubricant, compressed air or hydraulic oil is particularly common here. The rotary joints are also used on rotary tables with hydraulic chucks.

Based on our discussion, we develop an individual solution for each customer. Starting as a specialist for wind energy, we have built up a wealth of experience in a wide variety of sectors over the past few decades – from the construction industry and the food industry to robotics and medical technology.

Pneumatic rotary unions - compressed air for tools and agriculture

A pneumatic rotary union for compressed air is also necessary in almost all industrial companies that work with clamping technology. Because, for example, in turning and milling work, it is not only the media supply of coolant, grease, oil or – in the case of hybrid electrical rotary joints – with measured values, electricity and control signals that is decisive. Compressed air also operates the spindle to allow the milling head to work.

What is needed here are hybrid multi-channel rotary unions that can simultaneously carry compressed air, coolant and lubricating oil – and without leaks. The pneumatics also enable easy and gentle cleaning of the components without having to remove individual parts from the machine tool. Compressed air is also used in robotics, namely whenever gripping and transfer movements are linked to rotary movements.

However, multi-channel rotary joints for pneumatics are not only used to simultaneously feed and return different media with precision, but also to exclusively feed compressed air – or another individual medium – to different points in a machine tool. This is the case, for example, with dynamic tire pressure control for commercial vehicles.

Dynamic tire pressure control is a basic requirement for modern agricultural and construction vehicles

Mobile agricultural machines – above all the tractor or combine harvester – drive on a variety of different surfaces. However, this also applies in part to construction vehicles. In agriculture, a tractor may have to drive over sand, clay soil, asphalt, fields, meadows and forest soil on one tour. At the same time, the machines are becoming heavier, and the trailers are becoming larger and larger. It is therefore a basic requirement for modern machines that the tire pressure can be dynamically regulated during operation and adapted to the ground to extend the service life of the tires and at the same time protect the ground. If the air pressure cannot be adjusted, the requirements for safety and service life of the tires and the requirement for protection of roads, farmland and forest soil are almost incompatible.

A high tire pressure on the road ensures a longer service life of the tire and more safety when steering and braking. On the field, or on soft ground such as forest floor or meadows, it promotes the so-called bulldozing effect, i.e., a large track depth and the associated high fuel consumption. A low tire pressure would increase the tire contact area and counteract the bulldozing effect.

In addition, high tire pressure leads to more compaction in soft soil and thus worsens the subsequent crop, while at the same time it makes it difficult for rainwater to seep away, which increases the risk of soil erosion and flooding. Dynamic tire pressure control during operation makes it possible to correspondingly increase tire pressure on the road and decrease it on soft ground. Rule of thumb: 0.5 bar to 1.2 bar in the field, around 2 bar to 2.5 bar on the road.

However, in day-to-day operations, operations alternate between field work and transport so frequently that manual adjustment of the air pressure with each change is very laborious. This is where the dynamic tire pressure control system comes into play. The air pressure must be able to be adjusted at the touch of a button via the controls in the driver’s cab – and this must be done during operation, while the tires are rotating. This makes multi-flow pneumatic rotary unions necessary, both in single-circuit and dual-circuit systems. The interface between the compressed air supply line and the rotating tire is always the rotary supply. It accepts the compressed air from the compressor (stator side) and directs it through the rotor into the tires. Combined electrical rotary feedthroughs also make it possible to transmit the measured values to the driver’s cab to display the current tire pressure. In this way, an additional electric slip ring can be saved.

Incidentally, this function can also be retrofitted to older agricultural machines, for which purpose the rotary union is mounted on the front edge of the axle hub. However, compact rotary feedthroughs such as those from rotarX also make it possible to install the rotary feedthroughs within the axis (in-axis constructions). Only the connection thread is then visible from the outside.

Rotary union for water

Rotary unions for water can be used in a wide variety of areas. Whether the water is used for cleaning, as a coolant or as extinguishing water. In a very simple form, water is used in single-flow rotary unions for sprinkler systems or lawn sprinklers if they are to be swiveling or rotating. The same applies to swiveling faucets.

However, water can also be used in multi-channel rotary feedthroughs, for example for the partial cleaning of the components of lathes and milling machines at intervals. Here it is usually combined with the passage of compressed air, vacuum, hydraulic fluid, emulsions or grease, of course clearly separated by high-quality sealing rings so that the media do not mix. In addition, our rotary unions are pressure-resistant up to a maximum of 1300 bar, so that they are also suitable for high-pressure cleaning systems, for example in car washes.

Rotary joints for vacuum

A rotary union for vacuum technology is intended to transmit rotary movements between atmosphere and vacuum. For example, the rotary motion of a motor shaft can be transferred to a hermetic chamber, i.e. a vacuum. To do this, the rotary feeder is installed in the wall of the chamber and thus forms the transition to the vacuum, which means that it acts as a passage for the movement. This is in demand, for example, in the field of glass processing. For example, to move glass substrates in a coating system or to turn optical glasses during processing in the vacuum chamber. Vacuum technology is also indispensable for the manufacture of individual components in the high-tech sector and the computer industry.

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

You can reach us Mon - Fri from 8 am to 5 pm.Do you have questions or would you like advice?

WE LOOK FORWARD TO YOUR MESSAGE

CONTACT