Slip rings for electrical signals, power transmission & data

Do you already know our configurator?

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

A slip ring allows the transmission of power and signals between stationary and rotating structures

The world of industry and electromechanics is always in motion. More precisely, in rotary motion (rotating consumers). Wind turbines, medical technology, crane technology, stage technology, video cameras, screens, data-driven automation, data transmission and robotics – standstill is the death of efficiency and innovation. None of these industries function without the transmission of power and data on continuous, unrestricted or intermittent rotation.

Therefore, reliable, maintenance-free and loss-free transmission of data, power and electrical signals between the individual stationary and rotating components is required. That’s were electromechanical devices come into play that allow that kind of transmission, regardless of the application or kind of rotation: slip rings. This may be components rotating incomplete revolutions in one direction continuously or rotating incomplete revolutions in either direction. Or they oscillate through parts of a revolution, depending on the application.

Slip rings are elementary for every industry in motion, such as:

To name just a few.

They do not only fulfill a purely technical function that cables could not perform in the transmission between two rotating or a stationary and rotating component. Slip rings also help to improve mechanical performance, simplify system operation, and eliminate the need for damage-prone cables hanging from moving joints. For a long time now, it has not only been about the transmission of electricity. Especially in the context of Industry 4.0, it is becoming increasingly important that slip rings can transmit much more and that under various requirements and a wide variety of rotation speeds. Our roots are in wind power, but over the last few decades we have been able to gain a lot of experience in transferring the requirements for space saving, reliability, speed, robustness and freedom from maintenance to other sectors.

Because it doesn’t matter whether it’s a human-robot collaboration, a filling system, factory automation, a sprinkler system, a rotary milking parlour or a CT device. They all require a combined transmission of signals such as Profinet, fieldbus, HD-SDI or video signals, data and power.

How do we realize electrical slip rings?

Since numerous mechanical components are always in rotation, which makes fixed power transmission or data transmission via cables impossible, slip rings are indispensable and almost maintenance-free and invisible electromechanical components. At the same time, slip ring assemblies and their sliding contacts are the heart of every automation system and machine, which, thanks to the brush (sliding contact), enables contactless power and signal transmission between stationary and moving components, or components rotating against each other, e.g. of video signals, Ethernet signals / Profinet, COAX, HD-SDI, fibre optic cables and field buses.

For this purpose, the slip ring assemblies must be manufactured according to your personal and industry-specific requirements and from the best materials, which enable fast, low-wear and loss-free transmission of data and power under a wide range of conditions and temperatures. Just like our slip ring assemblies and rotary unions from RotarX. As a manufacturer of slip rings, our focus is on the highest contact quality of the silver-to-silver and gold-to-gold sliding contacts and maximum life expectancy, while at the same time requiring the least amount of maintenance.

We deliver slip rings for many applications

- Rotating and slewing movements of a crane

- Filling systems

- Circular scraper (sewage treatment plants)

- Revolving doors

- Dump trucks

- 4K video image transmission

- Radar systems

- Computer networks

- Support arm lights

- Wind turbines

- Packaging machines

- Stage technology such as lifting platforms or rides such as roller coasters

Slip rings are therefore installed in numerous electrical machines and industrial systems in all sectors, whose components cannot be connected to fixed power supplies by cable due to their constant rotation. Thanks to their high material quality, robust construction, intelligent design and maintenance-free, high-quality contacts, rotarX slip rings and rotary joints guarantee highly reliable, low-wear data and power transmission between rotating components and stationary machines. Or between two components rotating against each other. The technology of our slip ring bodies is based on fibre brushes and fibre brushes as sliding contacts, which can also be combined with rotary unions for media such as water, hydraulic oil, compressed air and gases as required.

Transmission of electrical signals and data is becoming increasingly important

The ever faster and endlessly rotating data transmission of control signals, video signals and measurement data is becoming increasingly important. In addition to the standard current transmission, rotary joints for fluids (e.g., hydraulic fluid or oil), gases and compressed air complement the classic slip rings. We even offer hybrid combinations of rotary union and slip ring so that you can transmit data, power, electrical signals as well as liquids, gases or compressed air with just one component. We call them hybrid electrical and pneumatic rotary union that also include the transmission of liquids, emulsion and gases.

These are used, for example, in hydraulic chain excavators or for tire pressure control systems. With a tire pressure control system, they can not only transmit the compressed air, but also the measured values of the current tire pressure. In an excavator with a revolving superstructure, the return oil and hydraulic fluid reciprocation under high pressure can be realized, but also, for example, the level of the hydraulic oil tank can be transmitted. In the field of wind energy, they are used for pitch control and YAW control. For example, not only electricity or hydraulic fluid has to be transmitted to adjust the blade angle, but also the data from the anemometer to adjust the blades of the wind turbine to the wind direction and wind speed using the pitch motors.

The fast and error-free transmission of all data for energy production and maintenance via fiber optics also plays a major role, especially for offshore systems. Because offshore wind turbines are monitored from land. And since maintenance work on such wind turbines is significantly more expensive than on land, this transmission must function smoothly in the truest sense of the word. In addition, the slip rings are exposed to the particularly harsh conditions of salt water, which is why special know-how is required here.

What many people don’t know: slip rings in wind turbines are also used for lightning protection. The slip ring connects the rotating parts of the turbine to the stationary earthing system. Wouldn’t that be the case a flashover or arcing would occur if the rotor blades were stuck by lightning. That could lead to bearing damage due to welded joints in components that are rotating relative to one another.

At the same time, you benefit from many other advantages:

- Connectors can be fitted according to customer requirements

- freely selectable cable length

- individual cable entry

- Customised special designs even for small quantities

- EMI shielding of analogue, digital and HF signals possible

- Operating temperature up to 300°C possible

- Various fastening options

- Suitable for high voltage, control voltage or low voltage

- Low-wear and maintenance-free continuous operation with optimum dynamics

- Silver-silver and gold-gold contacts

- Open and encapsulated slip rings

Advantages of slip rings for data transmission:

- Suitable for up to 1 GBit/s (Ethernet)

- Stable performance and no loss of data packets

- CAT5E, CAT6 or CAT7E cable

- low noise

- Working temperature: -30°C to +80°C

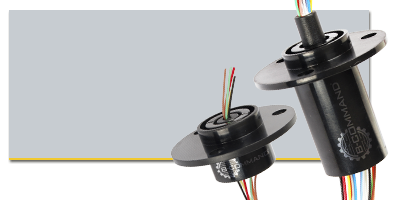

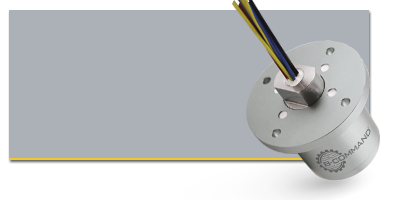

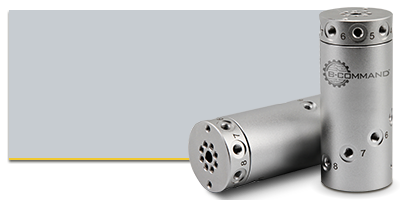

Slip ring bodies – modular system & standard series

All our slip ring bodies are available as standardised or modularised versions. This means that our slip rings can be completely customised to suit you and your business or intended use. If you have special customised requirements, we will be happy to advise you on the most suitable recommendation for your specification. Please feel free to contact us. This is the only way we can design the technically and economically ideal slip ring system solution for each customer. Combine different transmission technologies and contacting transmissions of electrical power, signals and data.

Our engineers will advise you on the ideal sliding contacts and brush, as these vary according to the current, voltage, rotation speed, bandwidth, impedance and operating temperature of the components.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

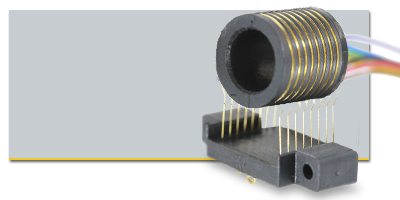

Construction of slip ring assemblies

The three main parts of a slip ring assembly (SRA):

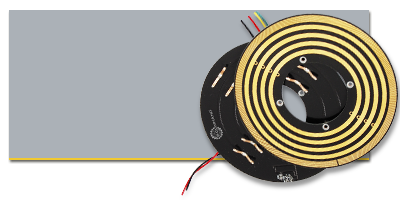

- A rotating part with conductive rings separated by insulation material: Common slip rings conductive rings planes are arranged parallel to each other. They form a cylinder. But some slip ring assemblies have concentrically arranged rings in the same plane (they are called pancake slip rings). Pancake slip rings are the perfect solution for minimum installation heights. Vertically arranged rings and pickups enable use wherever the installation space in the direction of the longitudinal axis is limited.

- Stationary brushed of the strator: Put simply, data, power and signals are transmitted by the friction of the brush of the slip ring on the component. The materials selected for the brush contacts vary depending on the specific application. We rely on brush technology with low electrical noise, for the transmission of fieldbuses with high data rates, low contact pressure for a long service life and freedom from maintenance.

- The customers needs: For example, you can choose between fiber brush and fiber brush technology, different materials such as aluminum and plastic, and precious metal contacts such as the silver-on-silver and gold-on-gold multi-contact. We are aware of the growing importance of reliable and maintenance-free signal and energy transmission in the context of Industry 4.0. In the future, almost every component will no longer only fulfill a mechanical function but must also be able to transmit data and other signals.

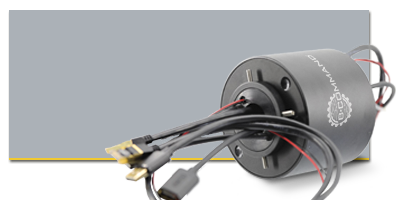

An example of our slip ring assemblies

Automation Slip Rings

These factors & functions should be considered by engineers for slip rings

You can also obtain slip rings from the manufacturer rotarX as a standard variant. However, slip ring systems are usually individually designed solutions, depending on the respective area of application from robotics to wind power. There are numerous factors that should be taken into account here:

- HF shielding

- Processing of the signal mix

- Contact resistance

- Matching of high frequency impedances

- Operating temperature

- Product life cycle

- Weather resistance and environmental conditions

- Available space in the installation room

Modern technology now lives not only from a reliable power supply, but also from the connection to the Ethernet. The broadband requirement therefore faces the challenge of electromagnetic interference (EMI) more than ever. Ethernet signals and power must be passed on in combination via slip rings from stationary to rotating components (and vice versa). These react sensitively to external electromagnetic interference. Here our experts have the know-how of special HF design techniques to shield motor applications from EMI. This prevents data integrity from being compromised. We pass on these techniques for so-called RF shielding and physical isolation to you as a product and knowledge transfer. Here it is of enormous importance that the shielding is done via a separate channel in the slip ring, which completes the electrical connection between rotor and stator shielding. In this way, the shielded energy benefits from optimal earthing via this separate channel.

In addition, data integrity is improved by reducing electrical brush noise. This is an accurate measure of the contact resistance of each channel as the slip ring rotates. You will find exact details on the respective product page. Overall, you benefit from very low electrical noise due to our fibre brush technology. This is also reflected in the measured quality of the data signal transmission, which is given in lost packets per million.

Last but not least, industrial designers and engineers need to know the environmental characteristics of the installation space and the machine. These have a great impact on the sliding contacts. A precise knowledge of the protection classes as well as shock and vibration, which affect the sealing requirements, as well as the type of sliding contact technology and the position of the contacts is a basic requirement here.

You should pay attention to these criteria when buying a slip ring:

- Transmission technology– how is current and / or signal transmitted from the stationary component to a rotating component?

- Connectivity– how is the electrical connection created on stationary and rotating components?

- Operating speed– level of speed (rpm) of the unit?

- Housing- What materials and seals ensure the proper and reliable operation of the slip ring in the installation space?

These are the questions you should ask yourself:

- How many electrical channels are needed?

- What is the voltage and current of the channels?

- Which data protocol is used?

- Is the slip ring connected to the system or component via plugs or lead wires?

- Does earthing have to take place?

- How is the slip ring fastened?

- Which IP protection class and seals (e.g. to protect against contamination) are necessary in the respective operating environment?

- What atmospheric conditions and media (water, dirt, mud) must be taken into account?

- Does the slip ring rotate quickly and does the direction of rotation change during operation?

- How high is the load on the individual channels?

All in all, a multitude of aspects and factors have to be taken into account when designing a slip ring. That’s why you should make sure that a manufacturer makes its interest in improvement, innovation and new technologies clear and integrates them into its own processes – just like rotarX. After all, technology is advancing rapidly and the necessary transmission speeds and data volumes are growing exponentially. Therefore, you should additionally ensure that the slip ring can forward and process analogue and digital signals.

In addition, the slip ring should fit optimally into the design of your installation and the specific installation space. A mix of standard parts with configurable options such as transmission technology, connectivity, packing size and housing and individual designs for a fusion of slip ring and rotating union in one housing are the best approach here. A manufacturer and supplier who offers both types here in a kind of construction kit optimises the purchasing process and time-to-market – just like rotarX.