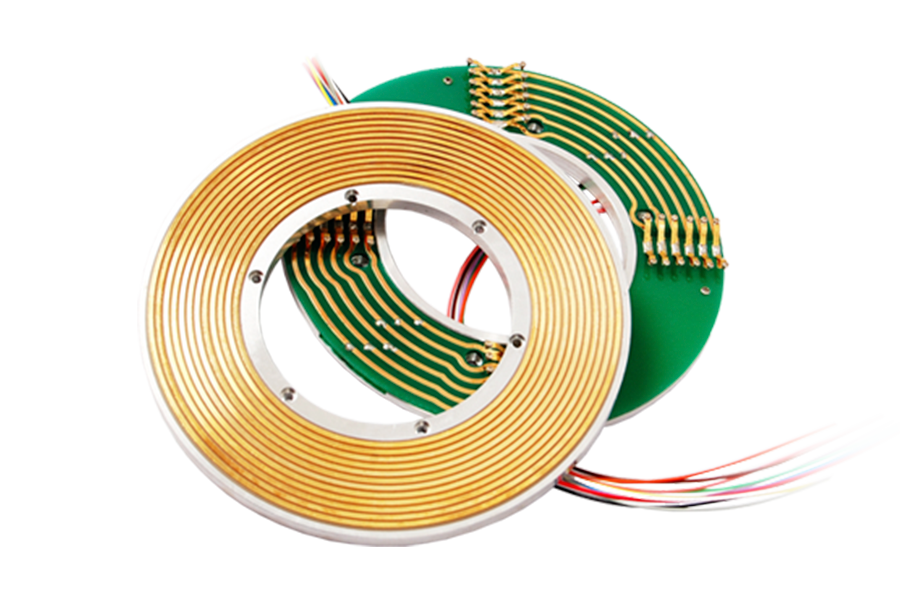

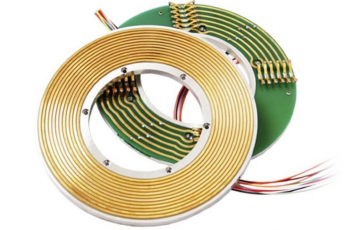

rotarX Pancake Slip Rings for Power and Signal Transmission.

Extremely flat slip rings with heights from 20mm to 91.9mm

Technical Specifications

Electrical Specifications

- Number of rings: 2-48

- Nominal current: 5-20A per ring

- Max. Working voltage: 240/440 VAC/DC

- Voltage withstand: ≥500V @50Hz

- Electrical noise: max 10mΩ

- Isolation resistance:

1000 MΩ @ 500 VDC

Pancake Slip Rings

Pancake slip rings for short shafts or especially many contacts. Pancake slip rings are the ideal solution for equipping short shafts with any number of contact options. These components get their name from their round, flat shape. This makes them look similar to pancakes. Other names for these components are flat slip rings or disc slip rings.

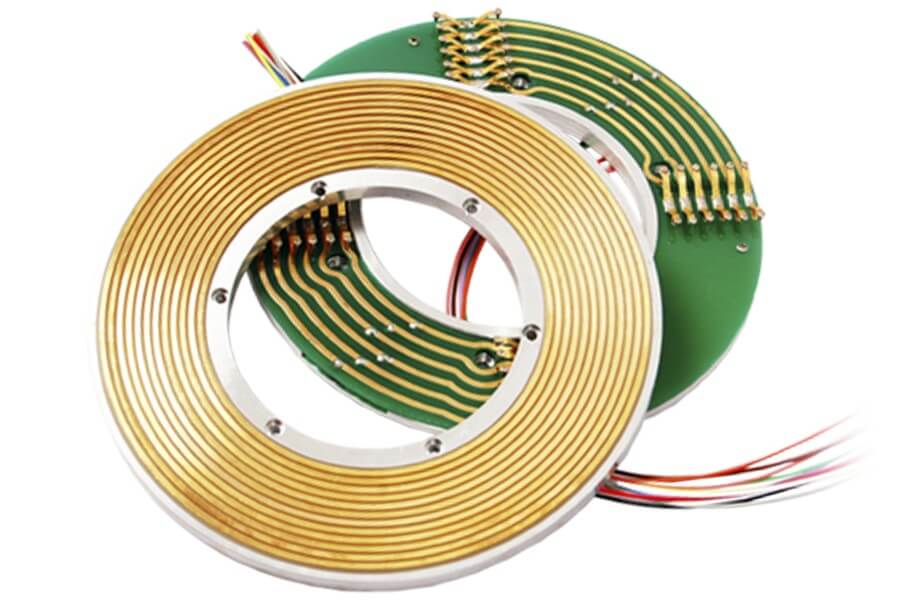

Their essential difference to conventional slip rings is that the transfer points are not arranged linearly, but vertically to the axis of rotation. This means that pancake slip rings can be very thin. In the vertical axis, however, they build up correspondingly high. This makes them ideal for installation positions where only a very short shaft is available but there is sufficient space in the transverse direction.

Pancake slip rings

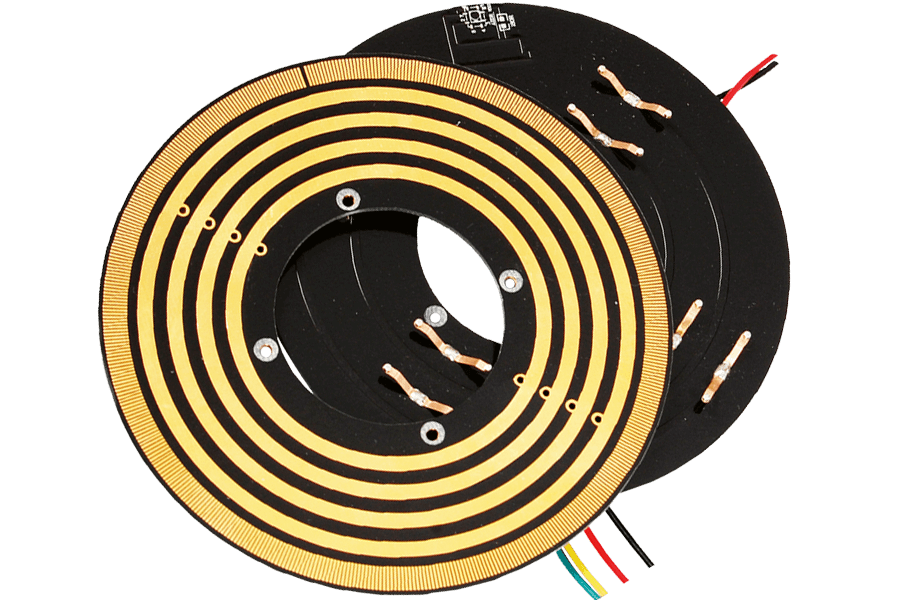

Structure of the pancake slip rings

Pancake slip rings consist of two plates facing each other. Contact rings are arranged in a circle on one plate. Each ring is soldered to a cable that is led out on one side of the slip ring in a string. The spring contacts are attached to the opposite plate. These are double or even quadruple. This ensures signal transmission at all times. The spring contacts are also soldered to connecting cables, which in turn are led out of the slip ring housing. Incoming and outgoing cables of the same colour are each connected to each other via a slip ring contact. This avoids confusion and facilitates installation. The two plates are rotatably connected to each other. They allow circumferential rotations of 360° and more. Depending on the design, the pancake slip rings are shielded against different influencing variables and permanently encapsulated against penetrating dust and moisture. This makes these components very durable and reliable. Versions without housing are also available on request.

Use of the pancake slip rings

Pancake slip rings are used wherever the installation space is limited in the longitudinal axis but is not critical transversely to the shaft. Since they build up quite widely, they are less suitable for high rotational speeds. The centrifugal forces and the vibrations otherwise increase so much that the vibrations can damage the disc slip ring.

Most components of this type are limited to rotational speeds of 300 rpm maximum. The most common use of pancake slip rings, however, is in actuation and control technology. They are often installed on multiple switches that activate other slip ring contacts in different switching states. Since the actuating pins of these switches are only very short, but there is usually plenty of space behind the housing, pancake slip rings are ideal aids at this point.

Other uses are, for example, slow-running servo motors that also need to rotate backwards. A particularly common application of disk slip rings is behind modern multifunction steering wheels. They reliably transmit the button commands for the car radio or the comfort displays to the actuators concerned.

Advantages of the Pancake Slip Rings

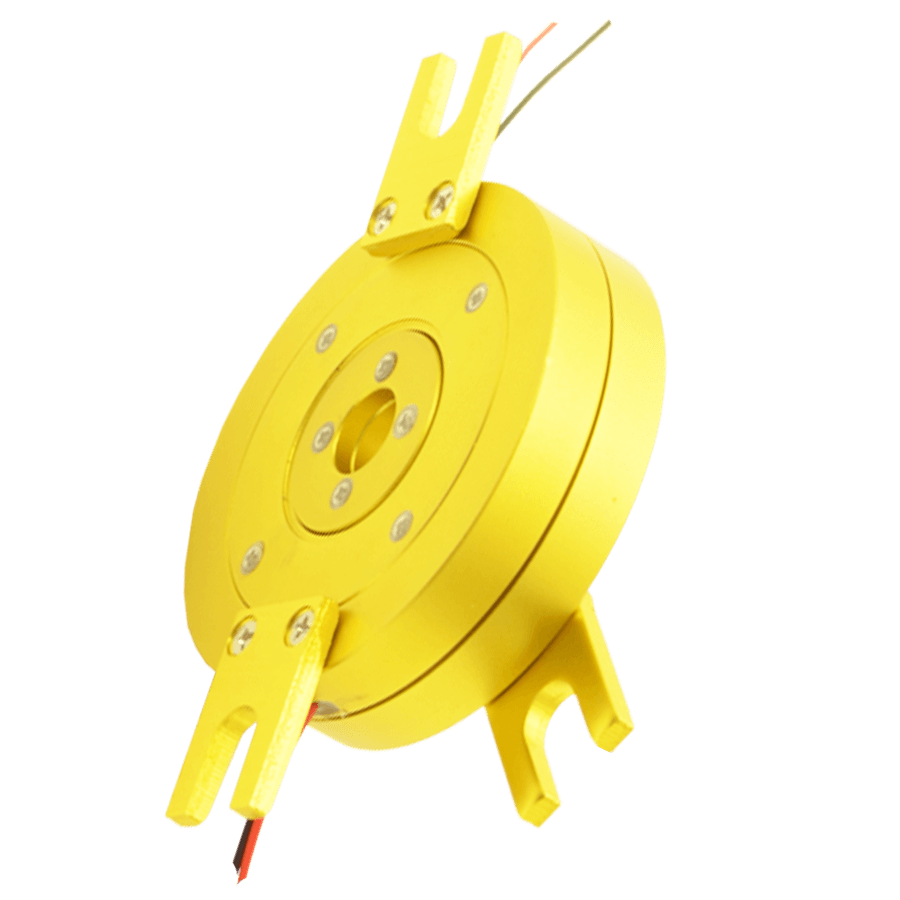

The biggest advantage of the pancake slip rings is their extremely low profile. They are only a few millimetres high and thus very space-saving along the longitudinal axis. Due to their increasingly larger contact surfaces towards the outside, the pancake slip rings also have good thermal behaviour. They are practically self-cooling due to their design. This cooling property is additionally supported by the use of aluminium housings.

Apart from the open design, the pancake slip rings are shielded to at least protection class IP 40, or IP51 or higher if desired. Like any component of this type, pancake slip rings are bidirectional. This makes them uncritical as far as their installation position is concerned. They always conduct current in both directions. If this is not desired, the incoming and outgoing wiring harnesses can easily be fitted with suitable electronic components, such as diodes.

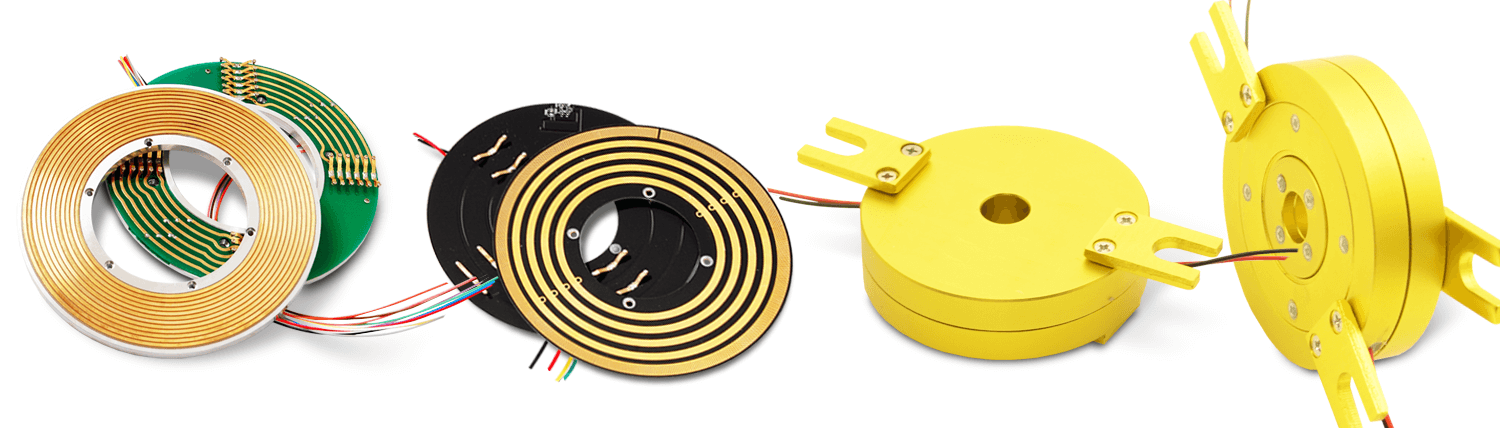

Another significant advantage of pancake slip rings is their expandability. In contrast to hollow shaft slip rings or shaft slip rings, the number of contacts on a single component is indeed severely limited. However, due to the low construction height, many pancake slip rings can be connected in series. This means that several pancake slip rings can easily accommodate hundreds of contacts on a single rotating shaft. However, the technical parameters, for example the rotation speed, must always be observed.

Disadvantages of the Pancake Slip Rings

Pancake slip rings quickly build up strongly across the longitudinal axis. This makes them less suitable in installation situations where there is not enough space. Their biggest disadvantage is their severe limitation of rotational speed. Where shaft and hollow shaft slip rings reach well over 1000 rpm, pancake slip rings are limited to a maximum of 300 rpm. This makes them an unsuitable component for fast rotating shafts, for example in air or pressure screws. If you have a need for high-performance slip rings for these applications, give us a call. We will find the right component for you.

Product variety of the pancake slip rings

The pancake slip rings are available with a ring number of 2 – 48. Higher ring numbers do not make sense, as they would enlarge the component too much. The larger a pancake slip ring becomes, the more sensitive it reacts to high speeds. Due to its small size, however, several pancake slip rings can be arranged in a row without any problems. The pancake slip rings are particularly well suited for this purpose. If this option is chosen, an additional protective housing with a suitable sleeve is recommended or required. With housing they are available in a thickness of 20 – 91.1 mm.

Without protective housing they have a thickness of 6 mm in all diameters. Their inner diameter (corresponding to the diameter of the permissible shafts) is up to 80mm. Pancake slip rings work safely at a speed of 0-300 rpm. Due to the use of silver-silver or gold-gold as contact material for rings and brushes, they are very corrosion resistant. Their temperature range is -30 °C to + 80 °C for all versions.

Repair of the slip rings

Pancake slip rings can be dismantled and can therefore theoretically be repaired comparatively easily. However, as these products are precision components, we would like to advise against makeshift repair attempts. Apart from occasional cleaning with a suitable acidifying agent, no major maintenance or repair work should be carried out on the pancake slip rings. We give a defined service life for each pancake slip ring. The low-priced components can be easily exchanged and replaced with a new part. This gives you a defined condition again that is reliably maintained until the next replacement interval.

Your way to the ideal pancake slip ring

We offer a comprehensive range of slip rings of all types. In addition to pancake slip rings, we also stock every other type of these special components from electrical engineering. If you cannot find the right solution for your challenge in our range, please contact us. Ideally, you should write us an e-mail explaining your project and attach a sketch.

In a joint discussion, we will clarify what the ideal slip ring for your application should look like. We will also be happy to manufacture special designs for you. You can order from us from quantity 1 to infinite. Trust our many years of experience. For decades, we have been supplying the world with slip rings of consistent quality that you can also rely on.

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.