rotarX Hollow Shaft Slip Rings for Power and Signal Transmission

Hollow shaft slip rings with hollow shafts from 3mm up to 300mm inner diameter

Technical Specifications

Electrical Specifications

- Number of rings: 2-144

- Nominal current: 2-10A per ring

- Max. Working voltage:

240 … 690 VAC/DC - Voltage withstand:

500 … 1000VAC @ 50Hz - Electrical noise: max 10mΩ

- Isolation resistance:

500 … 1000 MΩ @ 500 VDC

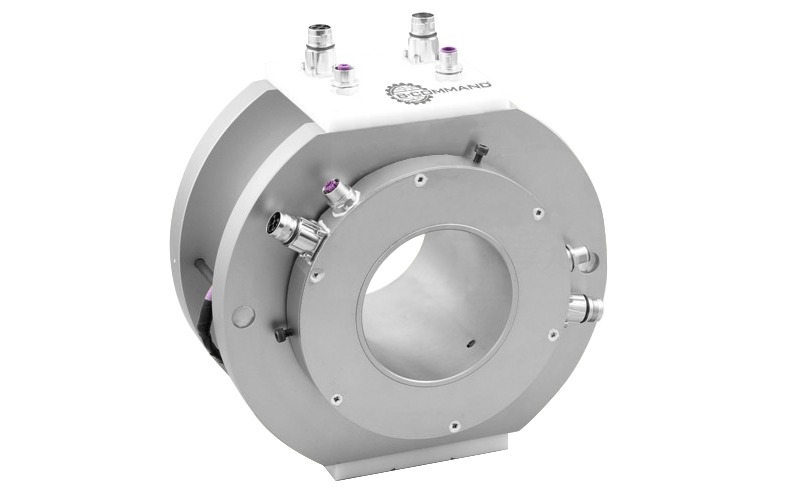

Through-Bore Slip Rings

Hollow shaft slip rings for maximum space efficiency where space is limited. Hollow shafts are rotating profiles with an open interior. As an empty tube, hollow shafts are suitable for installation on an axle or for cable feed-through. In addition, hollow shafts with a gas or liquid flowing through them are often found in hydraulic, pneumatic and media lines. To make them rotatable, the industry offers special couplings. These ensure continuous rotation through 360° without the user having to fear leakage. The hollow shaft slip rings are the ideal complement for these special kinetic profiles.

Hollow shaft slip rings

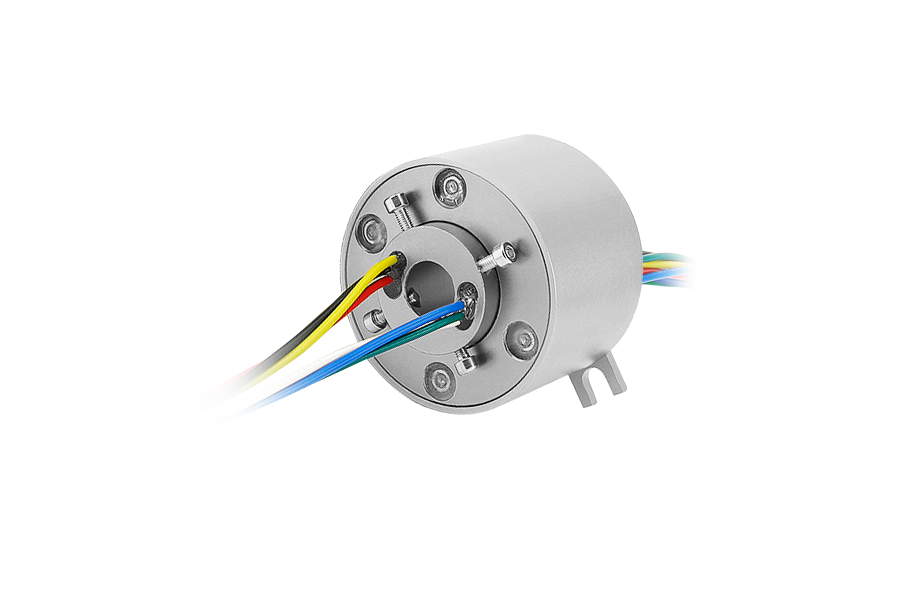

Structure of the hollow shaft slip rings

A hollow shaft slip ring, like any component of this type, consists of two sleeves that are rotatably inserted into each other. The inner sleeve is hollow so that it can be fitted onto a round profile. At the inner edge, the inner sleeve has at least one screw for a non-positive or positive connection with the profile that has been passed through. In addition, they have a small flanged holder on the outer ring. With the help of a groove or a screw, this can ensure that the outer sleeve does not rotate. The inner and outer sleeves are free to rotate, but have a very firm connection along the longitudinal axis.

This ensures that contact between the slip rings and the brushes is always secure. Wiring harnesses are soldered to each of the inner and outer contacts. They retain their colour so that confusion during assembly is impossible. The contact between brush and slip ring is maintained by an integrated spring. This prevents the current or signal transmission from breaking off even at high speeds. Hollow shaft slip rings are encapsulated. On request, they are available in waterproof or particularly impact-resistant versions.

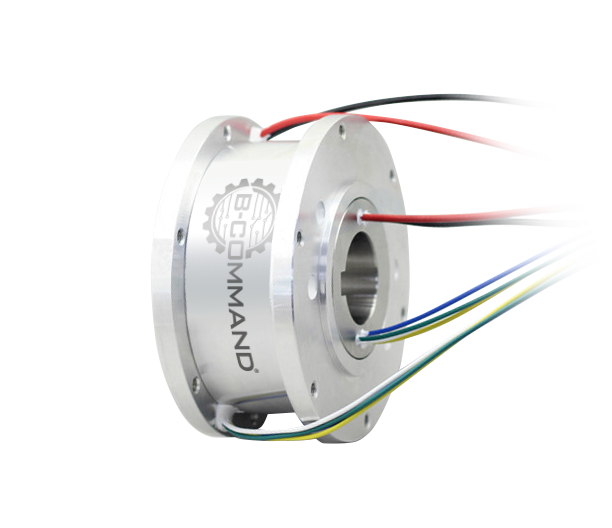

Use of the hollow shaft slip rings

A hollow shaft slip ring is fitted onto the hollow shaft. One or more screws fix the slip ring to the hollow shaft. With light loads, the clamping force is sufficient to fix the slip ring permanently to the shaft. If the wall thickness of the shaft is sufficient, the connection is improved by a screwed-in threaded hole.

The slip ring then has a positive connection that reliably prevents slipping. When using slip rings on media lines, it is important to ensure that the heat of the gases and liquids matches the operating temperatures of the modules. Hollow shafts are also very suitable for passing through the inner cable harness. It is thus protected in a particularly sustainable manner.

Advantages of the hollow shaft slip rings

Hollow shaft slip rings are suitable for both directions of rotation. They are designed in such a way that both the inner or the outer ring can be rotated or blocked. This makes their use very flexible. These modules are so robustly constructed that they can withstand speeds of up to 1200 revolutions per minute. This makes them easy to use for demanding applications, such as wheel hub motors. With protection class IP51, the slip rings are sufficiently tight against penetrating splash water or dust. The maximum operating temperature is 80 °C. This makes them suitable for hot water lines, hydraulic applications or compressed air ducts.

If the hollow shaft slip rings are to be installed on hot steam lines, an additional sleeve made of heat-insulating material is recommended. Hollow shaft slip rings are maintenance-free and have a precisely defined service life. As they are very inexpensive and easy to replace, their use ensures long-term operational reliability. In summary, hollow shaft slip rings offer the following advantages:

-

- Impact-resistant housing, also made of metal on request

-

- Maintenance-free and durable

- Acid- and corrosion-resistant outer material

-

- Reliable transmission of all power and control currents up to 690V

Slip rings are moving components. As a result, they are exposed to high mechanical loads. Even the smaller plastic housings are sufficiently impact-resistant against normal loads. In the metallic version, the hollow shaft slip rings can also withstand powerful lateral impacts. The slip rings can also be used in critical environments, for example in the vicinity of chemical or cooling lines. The transmission reliability of the currents is always guaranteed even at maximum temperature and highest speed. Our hollow-shaft slip rings are also sufficiently radio-interference suppressed so that they do not emit any interfering signals in the vicinity of transmitting and receiving equipment.

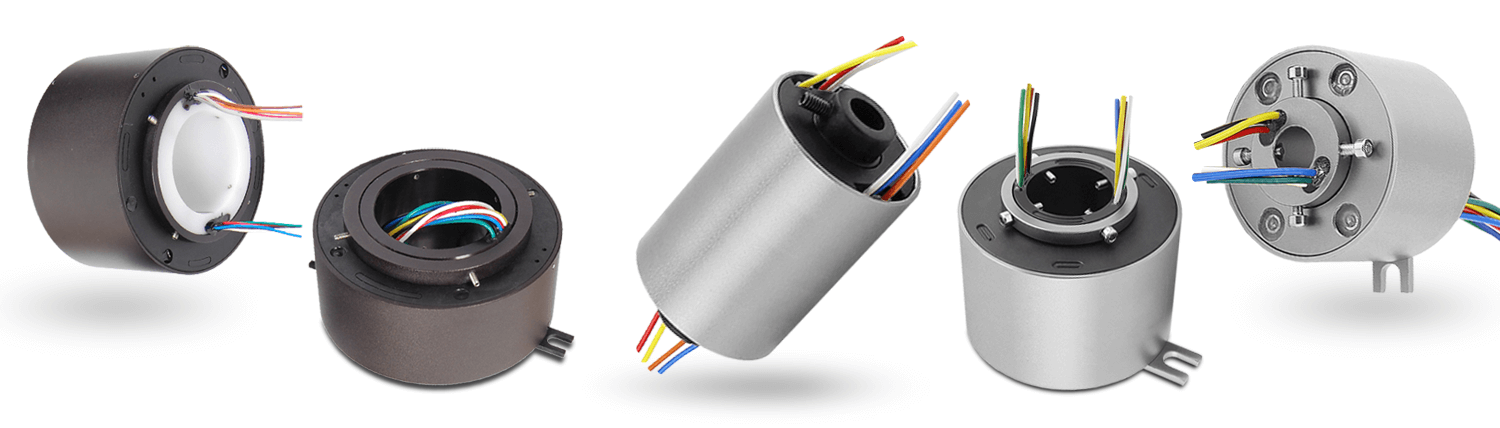

Product variety of hollow shaft slip rings

The hollow shaft slip rings are equipped with 2 to 144 rings. Each ring can be designed for rated current up to 10 A. Overvoltages are absorbed up to 500 – 1000 VAC. If voltage peaks above this are to be expected, additional fuse protection is recommended. The hollow shaft slip rings generate electrical noise up to a maximum of 10 mOhm. Their insulation resistance is 500 – 1000 MOhm at 500 VDC.

We offer the hollow shaft slip rings with an inner diameter of 30 – 300 millimetres. Gold-gold or silver-silver contacts are used as contact material in the modules. These precious metals produce only minimal abrasion and are particularly corrosion-resistant. The slip rings are equipped with a cable length of 300 millimetres on both sides as standard. The cables are of the same colour at the input and output. They can be used from -30 °C to +80 °C.

Installation of the hollow shaft slip rings

The installation of the hollow shaft slip rings is very simple. They are pushed to the desired position and fixed there with the clamping screws. If they are to be mounted on a solid profile, it is recommended to drill a threaded hole. This makes the connection form-fitting and particularly durable. A drop of Loctite ensures that the screws cannot come loose even in the case of strong vibrations.

Use of the hollow shaft slip rings

The hollow shaft slip rings are particularly well suited to round solid or hollow profiles of all kinds. Pipelines, plug-in axles or journals are typical installation locations for these modules. They can be used for power and data supply in a wide range of applications. Typical uses for hollow shaft slip rings are as follows:

- Rotary switches

- Servo motors

- Positioning valves

- Wheel hub motors

The special advantage of hollow shaft slip rings is their space-saving installation. The slip ring is simply slid onto a component that is installed anyway. Additional auxiliary constructions are not necessary for the installation of these modules.

This is how you get your ideal hollow shaft slip rings

We offer you slip rings of all kinds in a particularly large selection. In addition to our large range of hollow shaft slip rings, we can also supply you with completely new designs. We can supply you with quantities from 1 to infinite. If you are not sure which hollow shaft slip ring is the right one for you, please contact us. You can reach us by telephone via our customer hotline. Ideally, you should describe your challenge to us by e-mail and enclose photos and drawings explaining your request. We will contact you immediately and discuss the next steps. In a joint discussion at our premises or at your site, we will find the ideal product. Trust us and our many years of experience. Our slip rings stand for our quality and reliability in worldwide use.

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.