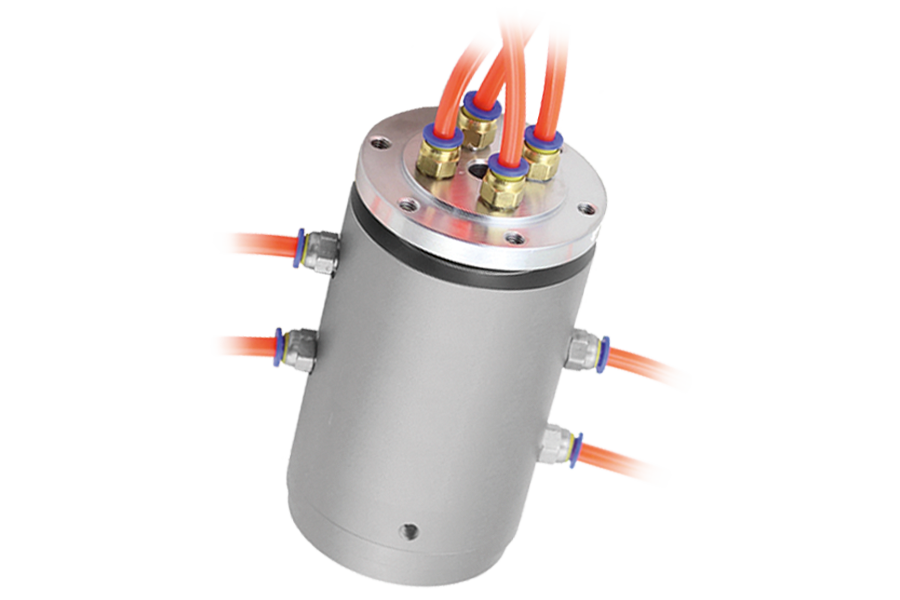

Hybrid electrical slip rings - combined electrical, hydraulic and pneumatic rotary unions

Compact slip rings for gas / liquid and electrical feedthroughs

Technical Specifications

Electrical Specifications

- Number of rings: 2-96

- Nominal current: 2-10A per ring

- Max. Working voltage: 220/440 VAC/DC

- Voltage withstand: ≥500V @50Hz

- Electrical noise: max 10mΩ

- Isolation resistance: 1000 MΩ @ 500 VDC

One for all: pneumatic liquid slip rings

If you are looking for an all-rounder among the slip rings, then you are well advised to choose our pneumatic liquid series. These slip rings offer you a 360° feed-through for all forms of media and energy that exist: Power current, signal current, pneumatics and hydraulics all find room in these compact but powerful slip rings. This gives you maximum design freedom in the smallest space for your applications.

Hybrid pneumatics/liquid + electrics

What do pneumatic liquid slip rings do?

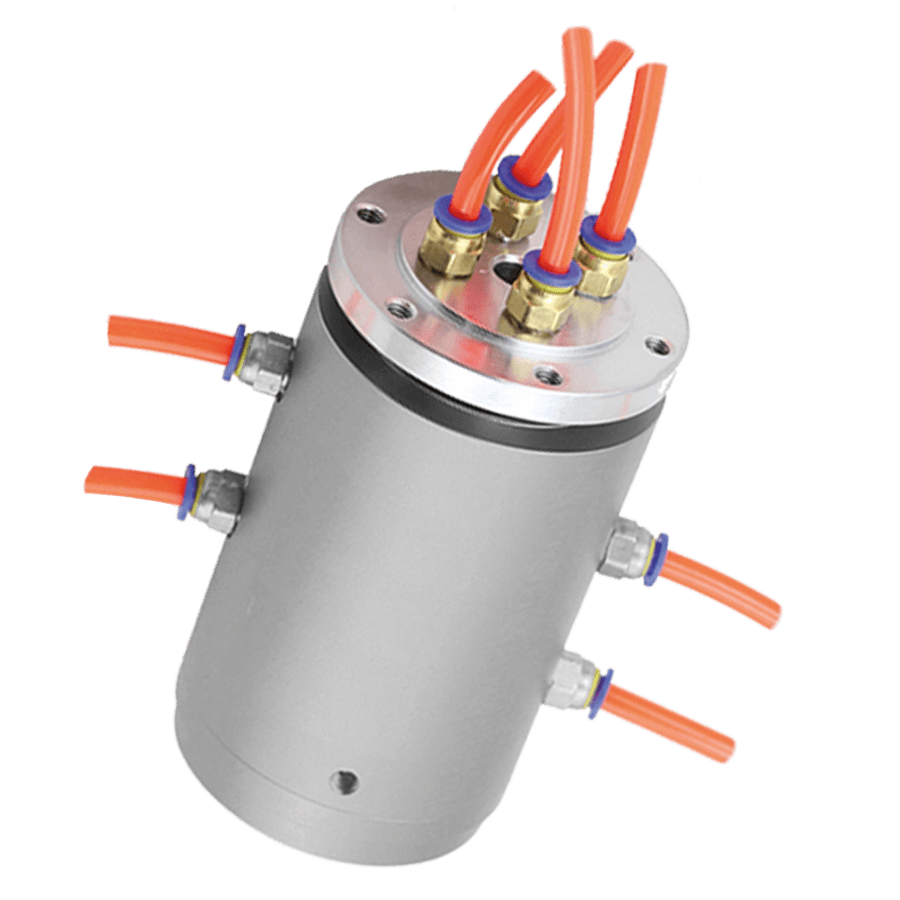

Pneumatic liquid slip rings belong to the “hybrid slip rings”. They are designed for the passage of more than one form of energy. The pneumatic liquid slip rings are among the most powerful representatives of their class. Their task is to guide any incoming energy form through a rotating union that can be rotated as desired – or vice versa. The return line from a rotating duct into a rigid duct is also possible without any problems. The pneumatic liquid slip rings perform enormously, especially when passing through hydraulic or pneumatic pressures: the components can be pressurised with up to 100 bar. This makes them ideal for particularly demanding applications.

Functionality of the pneumatic liquid slip ring

The pneumatic liquid slip ring can pass electric current, gas pressure and even hydraulic pressure. The electrical feedthrough is no different from the design used in any other slip ring. Corrosion-resistant silver-silver or gold-gold contacts are designed as a ring and a brush. The rings and the brushes can be rotated in relation to each other. Each ring-brush connection is assigned a pair of cables which are coloured in the same way. This makes assignment during installation particularly easy.

Passing gas pressure or hydraulic pressure through a slewing ring, on the other hand, is an enormous challenge. A complex duct system is created between the rotor and the stator for the passage of the media. In addition, a central media line ends in a rotating coupling. The weak point in this design is the sealing. However, by using high-quality sealing rubbers and sophisticated engineering, these lines can withstand up to 100 bar – and that at 300 revolutions per minute!

Special design difficulties with pneumatic liquid slip rings

This highest design stage of the hybrid slip rings has to cope with further difficulties in addition to the pure passage of the gas and liquid flows. The rotation of inner and outer housing creates constant friction. With purely electronic slip rings, this is not much of a problem. But where absolute tightness is required, rubbing rubber rings on plastic or aluminium are a limiting factor for the service life of the component. Nevertheless, the rotarX series has succeeded in guaranteeing these slip rings a service life of 10 million revolutions or more. In addition, the separation of all media-carrying lines is a major design challenge. rotarX was also able to solve this task with the pneumatic liquid slip rings.

Advantages of pneumatic liquid slip rings

Pneumatic liquid slip rings offer their users the following advantages:

- High load capacity

- Long service life

- Easy installation

- Reliable, sophisticated design

- Compact design

- Various applications

10 million revolutions at 300 rpm and 100 bar pressure are a real claim. The robust, tested and highly resilient pneumatic liquid slip rings withstand even the most demanding environments. At the same time, their installation is more than simple: the housing can be attached to any suitable component with standard screws. The connections for the media feed-throughs are standardised and can be connected with conventional tools. Once installed, the rotating unions perform reliably. Since they can pass on practically all relevant forms of energy with a single component, they are particularly space-saving. The possibilities for their use are correspondingly large.

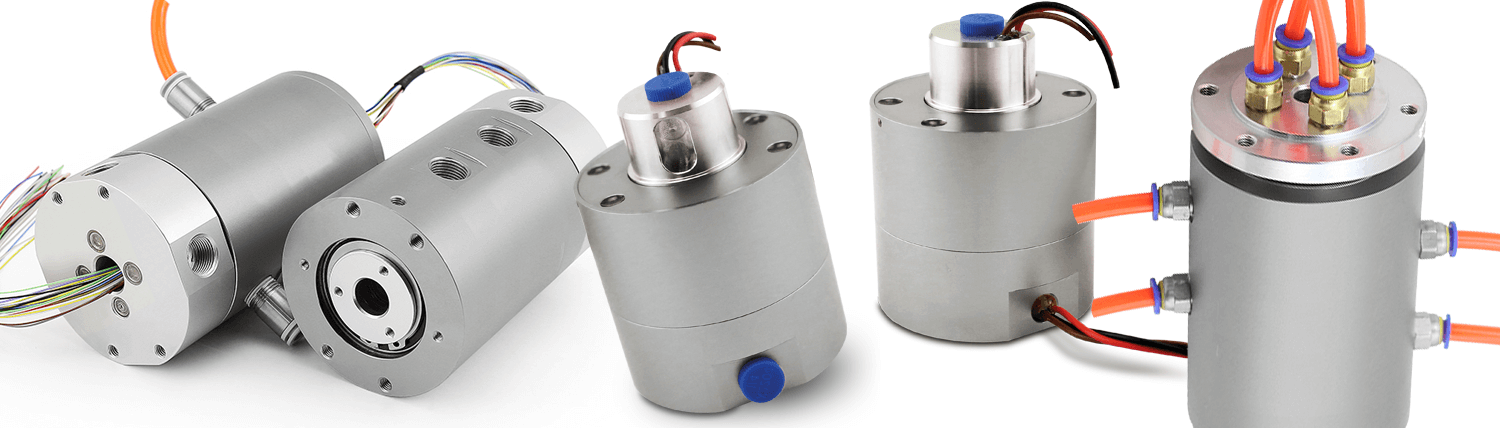

Product variety of pneumatic liquid slip rings

On the electrical side, the pneumatic liquid slip rings offer you a choice of two to 96 rings. Each ring can take a rated current of 2 to 10 amps. The permissible working voltage is 220 volts alternating current or 440 volts direct current. Each ring can withstand voltage peaks of up to 500 volts at 50 hertz. The maximum electrical noise is a negligible 10 milliohms. The insulation resistance of the pneumatic liquid slip rings is 1000 megohms and 500 volts DC.

There is a choice of one to 16 feedthroughs for pneumatics and/or hydraulics. The rotation speed is limited to 300 revolutions per minute. However, this is completely sufficient for most applications. The housing of the slip rings is made of stainless aluminium. The electrical part is designed for protection class IP51. The mechanical part can, of course, withstand much higher loads. The pneumatic liquid slip rings have a temperature range of -30 °C to + 80 °C. They can be loaded with 100 bar pressure. They can be loaded with 100 bar pressure.

Use of the pneumatic liquid slip rings

The media guides of our pneumatic liquid slip rings are not exclusive. This means that we can pass both liquid and a pressurised gas in this series. This makes very interesting combinations possible. In addition to the transmission of pneumatic or hydraulic energy, this also allows auxiliary and operating materials, such as coolants, cleaning agents or lubricants, to pass through. The possible applications are thus practically unlimited. However, these powerful slip rings are particularly popular for construction vehicles. Especially wheeled and tracked excavators with a rotating superstructure and hydraulic propulsion have at least one hydroelectric feed-through in the undercarriage. This allows the engine and hydraulic unit to be conveniently accommodated in the rotating superstructure and still reliably supply the rotating motors of the undercarriage with hydraulic pressure. Another application for these particularly powerful slip rings is in wind turbines. Here they are mainly used for hydraulic control of the rotor blade adjustment. They can transmit sensor data or luminous flux simultaneously with a hydraulic pressure that optimally turns the rotor blades into the wind.

Maintenance of the pneumatic liquid slip rings

Unlike the particularly small and very inexpensive electric slip rings, the pneumatic liquid slip rings allow a certain amount of maintenance. They can be dismantled and thus, for example, release the sealing rings for replacement. Nevertheless, the components should be checked carefully before each recommissioning: As long as only contacts and sealing rings are worn, the pneumatic liquid slip rings can be reconditioned without any problems. However, if the channels have nicks, scratches and cracks, their replacement is recommended. To prevent this as much as possible, we recommend keeping them as particle-free as possible by means of a filter before each media passage – including compressed air or gases.

How to get your pneumatic liquid slip ring

Pneumatic liquid slip rings are components for demanding applications. If you are not sure which slip ring is optimal for your applications, please contact us. Call us via our hotline or write us a message. You can use our contact form or simply send us an email. With drawings or photos you help our service to get an exact picture of your challenge. We will then work with you to develop the optimum strategy for your pneumatic liquid slip rings.

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.