Miniature slip rings for hydraulic and pneumatic

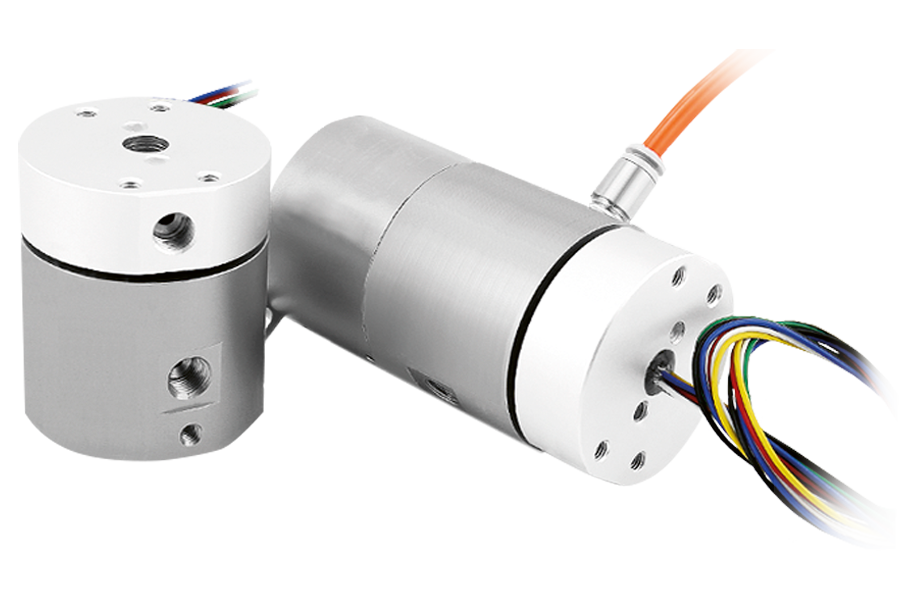

Compact Hybrid Slip Rings - Pneumatic / Liquid + Electric

Technical Specifications

Electrical Specifications

- Number of rings: 6 or 12

- Nominal current: 2A per ring

- Max. Working voltage: 440 VAC/DC

- Voltage withstand: ≥500V @50Hz

- Electrical noise: max 10mΩ

- Isolation resistance:

1000 MΩ @ 500 VDC

Safe transmission of electricity, liquids and gases with the miniature hybrid slip ring

The miniature hybrid slip ring belongs to the multifunctional slip rings. This means that it can reliably transmit more than one form of energy. Until now, these slip rings were only available in large and heavy formats. rotarX now also offers these powerful components in a compact version. This gives users, especially designers of hydropneumatic systems, completely new design options.

Hybrid miniature pneumatic/liquid + electric

Definition Miniature Hybrid Slip Ring

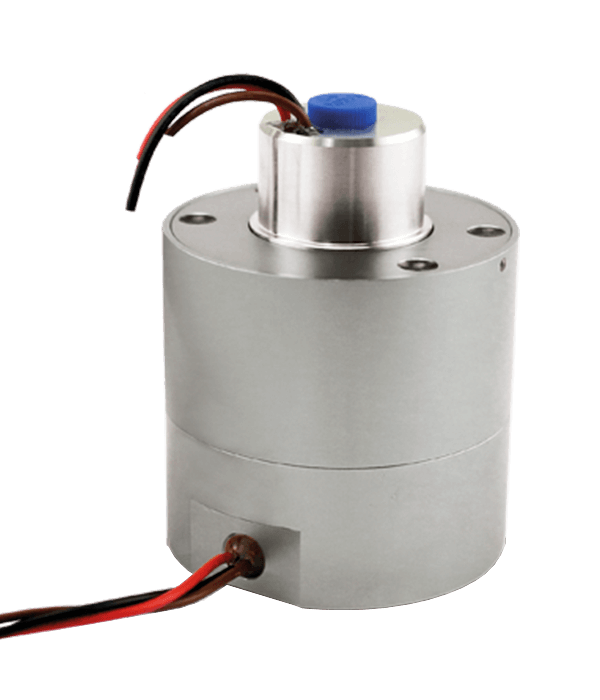

Slip rings have the task of converting a linear, rigid energy line into a rotating movement – or vice versa. Most slip rings work with electrical contacts. With these, the transmission of the electric current is relatively simple via sliding contact surfaces. When transmitting media-bound forms of energy such as gas or liquid, however, much greater challenges have to be overcome. Nevertheless, these sophisticated components are indispensable in many machines. They offer convincing quality with compact installation dimensions.

Functionality Miniature Hybrid Slip Ring

A miniature hybrid slip ring is a hybrid component that can conduct two different forms of energy: Electrical voltage and a medium (gas or liquid). This usually means that compressed air or liquid is passed through the miniature hybrid slip ring. However, low-pressure supply lines, such as oxygen or inert gas, can also be routed through this rotary joint. The electrical part is comparatively simple: it consists of incoming power lines, each of which passes a pair of ring brushes and is led out of the slip ring again on a cable of the same colour. In addition, however, there are one or more hydraulic or pneumatic connections on the slip ring. These use the space between the stator and the rotor. The gas or liquid is passed through a system of channels.

Advantages of the Miniature Hybrid Slip Ring

Miniature hybrid slip rings offer the following advantages:

- Low unit price

- Large constructive design possibilities

- High reliability

- Low weight

- Low installation space

- Easy installation

A rotating union that can pass gas pressure, liquid and electrical energy at the same time is a huge relief for designers. They practically only have to design up to the transfer points and can leave this critical point to a tested and proven series component. In addition, the hybrid design is space-saving. This makes it ideal for slewing rings where space is at a premium. Finally, the miniature design is also very low in mass. The low weight not only has energy-saving properties for vehicles and aircraft. It also has great advantages for dynamically exposed positions. Robot arms equipped with these lightweight components at intermediate joints generate significantly lower impulse forces during acceleration and deceleration from rotational movements. This protects the entire structure and extends the service life of the bearings in your application.

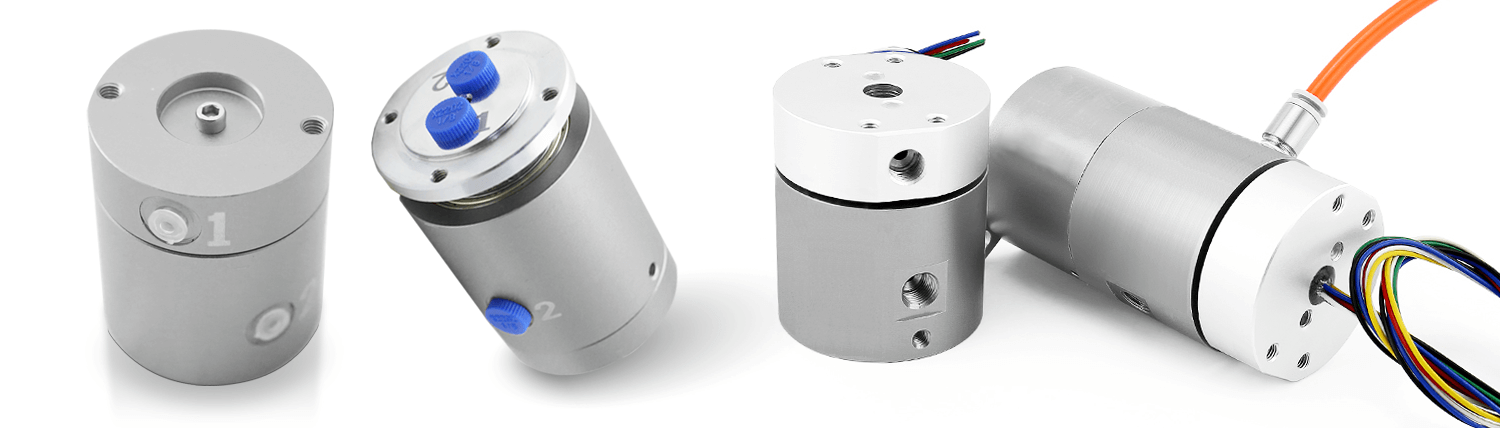

Selection of miniature hybrid slip rings

We offer miniature hybrid slip rings with six or twelve rings for the transmission of signal current. Each ring is designed for a rated current of two amperes. The maximum working voltage is 440 volts, both for direct current and alternating current. The slip rings tolerate voltage peaks of about 500 volts at 50 hertz frequency. The electrical noise is limited to 10 milliohms. The maximum insulation resistance is 1000 megohms at 500 volts DC. There is a choice of one to four passages for gas pressure or liquid transmission. Each hybrid slip ring allows a rotation of up to 300 revolutions per minute. The contact material for electrical transmission can be selected between silver-silver and gold-gold. This ensures corrosion-free operation. The standard diameter of the slip ring is 36 millimetres. Stainless aluminium is used as the housing material. The standard protection class is IP 51, which provides sufficient protection against penetrating dust and splash water. Higher protection classes are available on request. The temperature range of each miniature hybrid slip ring is -30 °C and +80 °C.

Application and use of the miniature hybrid slip rings

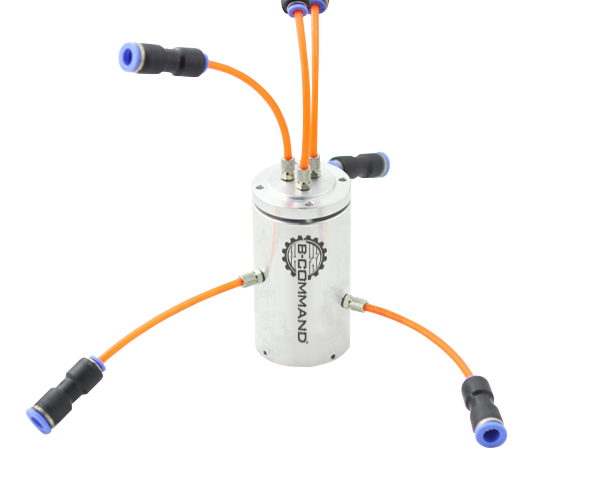

The miniature hybrid slip rings are used wherever electrical energy, gas pressure and liquids have to be conducted through a rotary joint. These do not always have to be pressurised media. The passage of supply lines is also ensured by these components. The miniature hybrid slip rings are particularly popular for conducting lubricants such as thin-bodied oils or industrial water as a cooling medium. They are therefore ideal for connection to lubrication nipples or central lubrication systems. Our service department will be happy to advise you.

The larger versions of these slip rings are mainly used in the construction of wind turbines and construction machinery. They support the transmission of hydraulic forces for pitch adjustment of the rotor blades or for the transmission of hydraulic pressure to the rotation motors of a chain drive. The miniature hybrid slip rings can effectively support their larger relatives in these positions. In addition, these components have proven themselves in the design of industrial robots or automated placement, removal and feeding systems. They allow a variety of motion axes and can ensure a targeted supply of lubricants and operating materials.

Another interesting application for miniature hybrid slip rings is the construction of automatic gas-shielded welding machines. In this application, the media line is used to pass inert gas. With the slip ring, power for auxiliary equipment, for example lighting, sensors or cameras, is fed to the actuator at the same time as the shielding gas. This makes for extremely compact, lightweight and highly versatile installations.

Your way to your miniature hybrid slip rings

We are happy to supply you with the right miniature hybrid slip rings for your applications. If you are not sure which products are ideal for your challenges, please contact us. These components are extremely flexible and versatile, so use our technical advice to project the optimum slip ring body for your application. For quick enquiries, our telephone hotline is at your disposal. You can use our contact form to describe your request in detail. If you would like to send us further information in the form of drawings, please send us an e-mail. Our service team will deal with your request immediately and get back to you as soon as possible.

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.