Packaging machines

Common applications for rotarX slip rings in Packaging Technology

- Packaging machines for food

- Packaging machines for pharmacy

- Packaging machines for cosmetics

- Thermoforming lines for the packaging of food and non-food articles in a protective atmosphere

- Filling systems

- Mechanical palletizing systems

- Robot controlled palletizing systems

- Stretch Packer

- Shrink film machine

- Cartoning systems

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

High-speed logistics for short throughput and delivery times

Modern logistics and packaging technology are geared to high process speeds and short throughput times. Improvements in these areas can be achieved on an ongoing basis through ever better networking of the systems with each other and ever faster communication and drive solutions. The transfer of data and power from all fixed to rotating parts must also keep pace with this development and therefore our rotarX slip rings are also undergoing permanent optimisation with the aim of improving their mechanical and electrical properties. Highest signal quality for 1000MBit Ethernet transmission, USB3.0 transmission and optical transmission via fiber optics are only a few possibilities of our program.

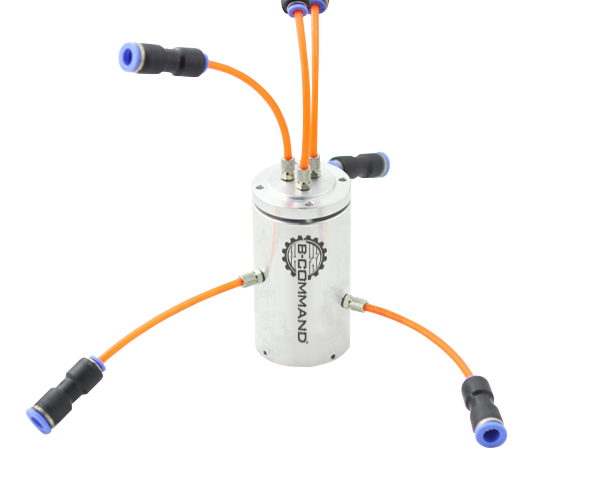

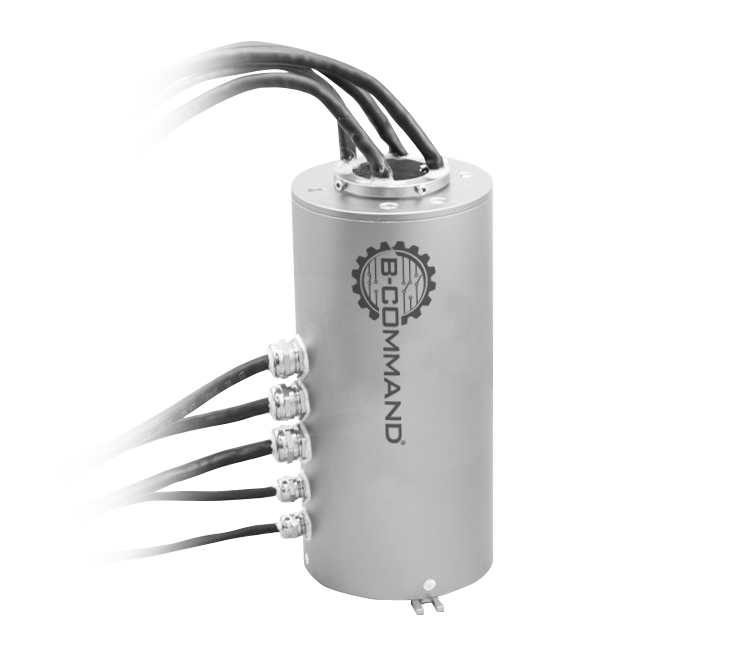

Slip rings in stainless steel housing / IP69K

For packaging solutions in the cosmetics, medical, pharmaceutical and food sectors, we use EHEDG-compliant materials and mechanical designs that are optimally suited for use in the critical areas. We use stainless steel A2 A (AISI 303 / EN 1.4305) and rust- and acid-resistant steel A4 (AISI 316L / EN 1.4435) as enclosure materials. The seals and cable types are also adapted to the requirements to ensure maximum tightness and maximum resistance. We offer IP69K as the maximum protection class for slip rings in these areas.

rotarX slip rings with short installation and maintenance times

Especially with high production rates and high throughput speeds, the service life and maintenance cycles of a slip ring play a significant role. The rotarX slip rings can be precisely adapted to the customer’s specifications and thus to the required running times through maximum customisation. A wide range of relubricating ball bearing slewing rings, robust sealing materials and precisely matched materials for rings and brushes are available for this purpose. Almost all slip rings in our production programme are maintenance-free and, with service lives of 100 million revolutions and more, can provide very long maintenance intervals. For maintenance purposes, all slip rings can be designed as plug-in units, so that short installation times can be ensured.

Advantages of rotarX slip rings for packaging lines

- modular design and flexible adaptation to different machine types

- Hybrid slip rings for combined transmission of power, signals and liquids/gases (media feed-through)

- long service life up to over 100 million revolutions

- high data rates for data transmission in bus networks

- Operating temperatures from -40°C to +200°C

- maintenance-free

- Housing material stainless steel A2 A or stainless and acid-resistant steel A4

In the field of packaging technology, rotarX slip rings from B-COMMAND offer many individual possibilities. Our engineers will also develop the right slip ring for your packaging application. Extensive technical data sheets and 3D models are a matter of course for us and offer our customers the possibility of simple design-side implementation of the devices. The satisfaction of our customers is our top priority.

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.