Common Applications for rotarX Slip Rings in Crane Technology:

- Tower cranes

- Bucket wheel excavator in opencast mining

- Mobile cranes

- Cable reels for gantry and harbour cranes

- rotating superstructures fire engines

- Excavator in construction

- Pillar jib cranes

- Attachments for cranes (jibs and grabs)

Power transmission for mobile cranes by means of slip rings

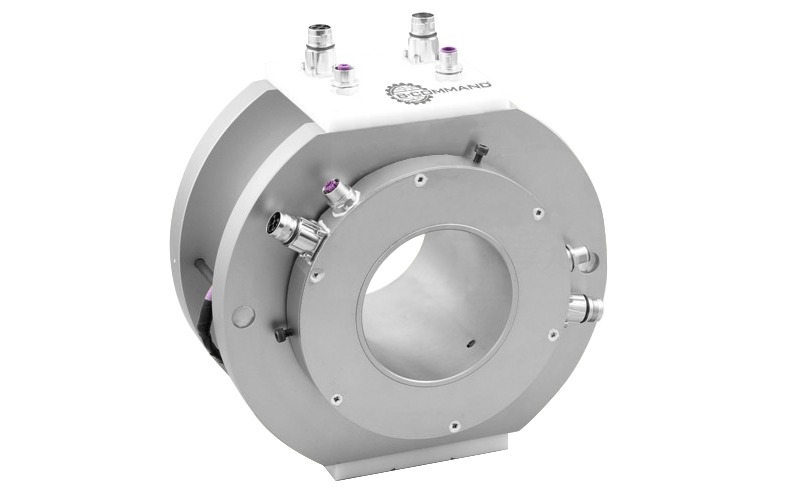

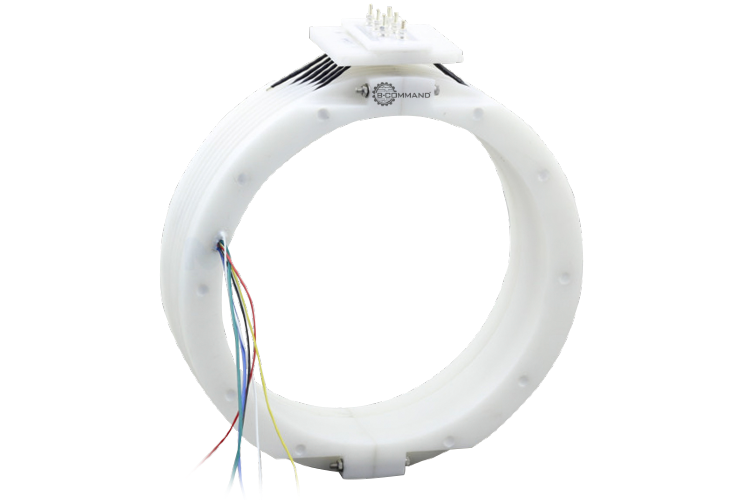

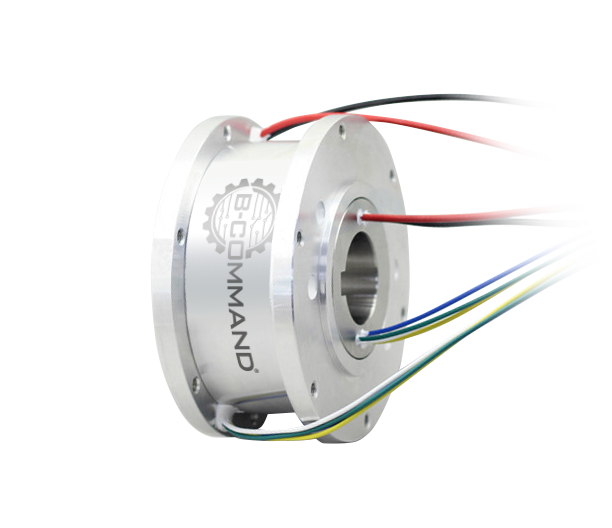

The modular system of rotarX slip rings offers maximum flexibility and a wide range of possible applications. The slip rings on mobile cranes and ladder trucks are used in the centre of rotation between the upper and lower structures. The electric drives and the sensors of the rotating booms must be safely connected in order to exclude risks for the operator. The rotarX slip rings offer the optimum solution for this. Hollow shaft slip rings also allow cables or hydraulic lines to be fed through the inside of the slip rings. Optionally, B-COMMAND also offers hybrid rotary transformers for the combined transmission of electrical power/signals and hydraulics.

Advantages of rotarX slip rings in crane technology

- Compact size, easy installation, high reliability and long operating time

- Transmission of fieldbus signals: Profibus, Profinet, CANopen

- Data transmission via optical fibre

- https://www.rotarx.comSchutzart up to IP68, suitable for use in dusty and exposed environments

- noble contact materials, high conductivity, low starting torque

- shock-resistant design, can also be used with high vibrations

- extremely temperature resistant

Customized slip rings from B-COMMAND

B-COMMAND develops and manufactures rotarX slip rings specifically for each application. Housing material, protection classes, combination of power and signal rings, operating and storage temperature, acceleration, mechanical vibration and cable lengths and types are individually designed. Due to the modular design of the slip rings, an almost infinite number of combination possibilities can be provided.

rotarX slip rings from B-COMMAND offer many individual possibilities in the field of conveying and lifting technology and in crane construction. Our engineers also develop the right slip ring for your crane-technology application. Comprehensive technical data sheets and 3D models are a matter of course for us and offer our customers the simple possibility of simple design-side implementation of the devices. The satisfaction of our customers is our top priority.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.