for wind turbines

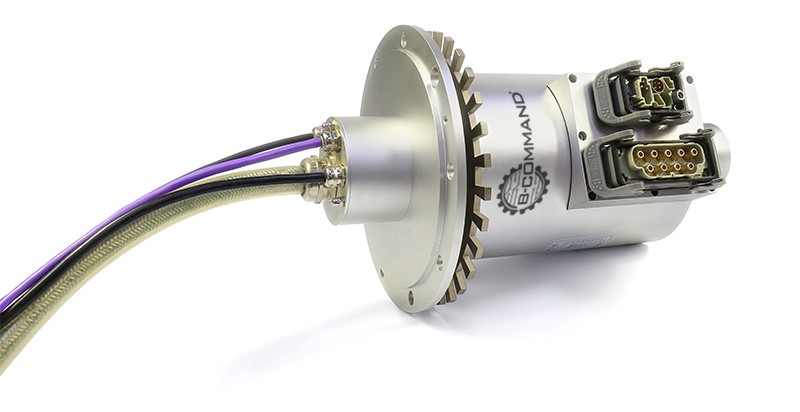

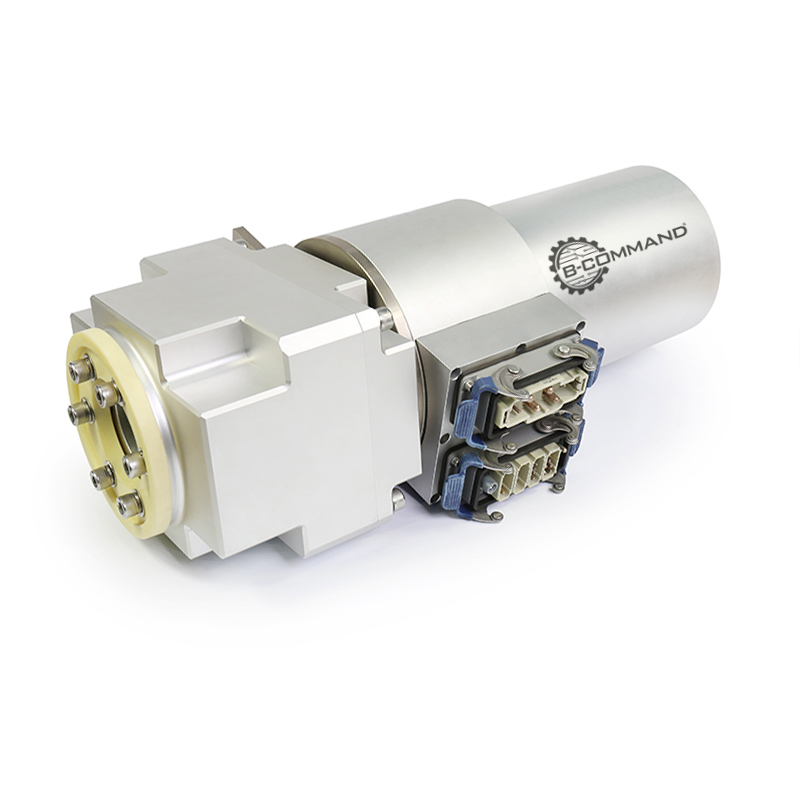

Within the wind turbines, the slip rings are assigned a wide variety of safety-relevant tasks which have a major influence on the availability and efficiency of the machines. rotarX slip rings are therefore specially designed for such applications and can offer corresponding differences, particularly in the areas of performance and quality. The wind power-specific requirements in terms of shock and vibration, extreme temperature differences and, if possible, maintenance-free design are also a fundamental part of our design.

Innovative slip rings for wind turbines

Demanding environmental conditions and the desire for a long service life of the slip rings lead to ever new solutions for the system manufacturers. Some examples of this are special seawater-resistant housings, which are tested for suitability for use in the offshore sector with extensive salt spray tests, and special materials for rings and busts, which ensure the long-lasting and trouble-free operation of the systems with the help of special gold wire technology.

Advantages of rotarX slip rings for wind turbines

- compact dimensions

- rugged construction

- high availability and low downtime

- Operating temperatures from -40°C to +60°C

- extremely long service life due to gold wire technology

- modular design and flexible adaptation to different plant types

- simple installation

Modular design of slip rings for wind turbines

The requirements and complexity of the slip rings differ greatly according to the different types of wind turbines. While small wind turbines are equipped with few sensors and relatively low power must be transmitted, the focus in this area is particularly on economic solutions with compact designs. In multi-megawatt systems, on the other hand, the requirements in the area of power transmission and also in the area of data transmission for the various BUS systems (Profibus, Profinet, CANopen, Ethernet 100 Base Tx) are significantly higher. For this reason, the rotarX slip rings are modular and can be designed according to the type of system to ensure optimal integration.

Slip ring with encoder

Through the combination of slewing rings and positioning technology, the plant operator can be offered a corresponding added value. The mounting of various rotary encoders on the slip rings enables the position of the rotating parts to be recorded in addition to pure transmission. For this purpose, we provide multifunctional mounting options for rotary encoders in our slip rings, which can be equipped with the encoder types required depending on the type of system.

Integration of slip rings in wind turbines

We also try to offer our customers a variety of options in the area of integration within the systems. Individual combination of power and data cables, adaptation of flange dimensions and drill holes, integration of connectors, integration of heating elements and individual cable types and lengths are just a few examples. Together with our customers, we reduce the risk of errors during assembly through plug-and-play solutions and thus ensure smooth installation.

New slip ring technologies for wind turbines

Developments in the field of Industry 4.0 and the increasing integration of sensor technology within plants are also presenting manufacturers of slip rings with new challenges. Especially the data transmission within industrial networks is developing rapidly and by using passive optical rotary transducers we can offer appropriate solutions. In addition to very high data rates, the maintenance-free use is also an advantage of lightwave rotary transmitters.

With its rotarX slip ring family, B-COMMAND offers a wide range of solutions for the wind turbine sector. This also includes slip rings with hollow shafts for electro-hydraulic pitch systems, which allow cables and hydraulic lines to pass through the free space inside.

The modular design of the rotary transformers and the adaptation to the plants are our main focus. We would also be happy to create an individual solution for your requirements. We look forward to talking with you.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.