The technology of rotarX

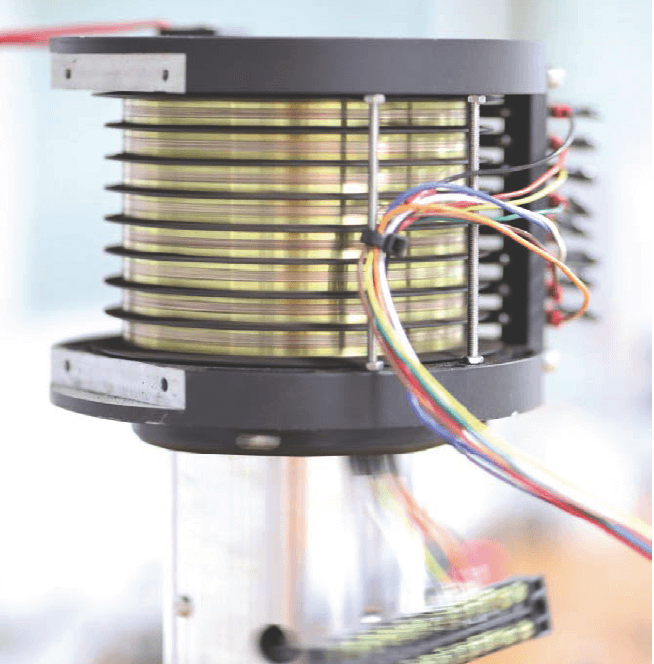

Slip rings are important electromechanical components for commercial or industrial machines. Their function must ensure the power transmission and signal transmission of data, media, energy and electrical signals under the best possible conditions. And this is between components that rotate against each other and components in electromechanics that do not allow fixed transmission via cable due to the constant rotary movement. Slip rings are also used for the transmission of signals and power between stationary and rotating components, for example in the field of wind power, roboticsor crane technology. Furthermore, there are special hydraulic slip rings whose functional principle enables the rotary transmission of fluids and air, e.g. for the transmission of hydraulic fluid. For this purpose, a slip ring must meet numerous industrial requirements, which above all must ensure high system availability, loss-free power and signal transmission and maximum freedom from maintenance.

This can only be achieved through thecombination of a targeted design process, the selection of the best raw materials, professional production conditions, 100% quality control and professional assembly at the customer’s site. Equally important is the possibility of modular adaptation of the slip ring systems to the respective area of application. Furthermore, our products function in a wide range of harsh environmental conditions and temperatures. They guarantee stable transmission even in salty and corrosive air and at temperatures from -30 to +80 degrees Celsius. That’s why rotarX not only supplies you with standardised slip rings, but also allows you to put together your own system, just like in a modular system. Our knowledgeable experts will advise you from the sketch to the installation in your company.

Premium Engineering

With years of experience and in-depth knowledge of all relevant engineering disciplines, the rotarX engineering team can provide fast and innovative design solutions for customers around the world. Our engineers are constantly developing new designs and using new materials in a wide range of different conditions.

To ensure only the highest quality products, rotarX is additionally able to perform the following tests in our in-house laboratory:

- Humidity test

- Temperature test

- Ingress protection test

- Vibration/shock test

- High pressure/vacuum test

- Torque test

- High voltage test

- High current test

- Salt spray test

- Stress test

- Electrical noise test

- Contact resistance test

- Duration test

- Isolation test

- Frequency test

- Friction test

Quality management

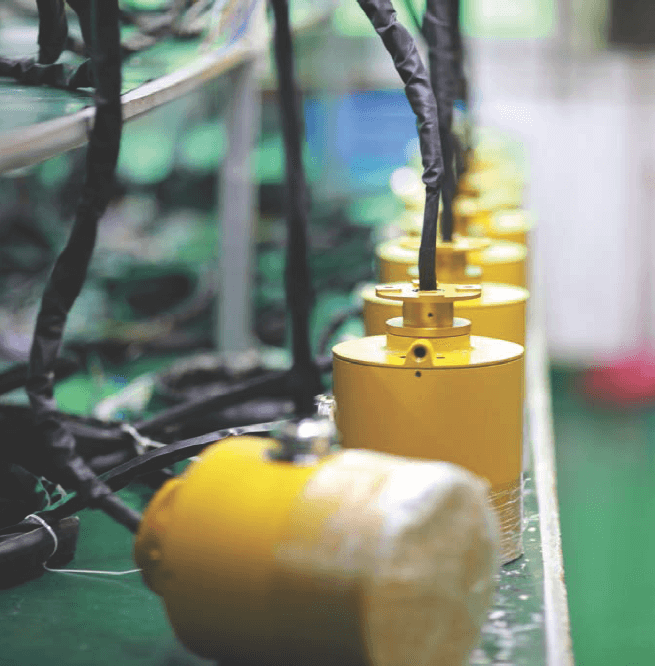

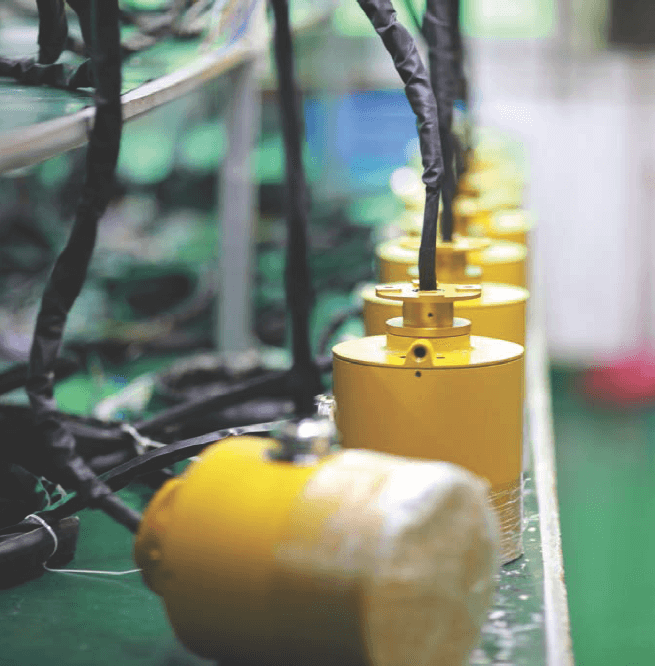

A high level of vertical integration is the key to seamless quality control. That is why rotarX has created expanded capabilities in the electrical and mechanical production of slip rings. Various automatic and semi-automatic multi-axis CNC machining centres, grinding machines, milling machines and coating machines offer a wide range of mechanical options during the production process.

Only experts with many years of experience operate our machines to guarantee our customers the best quality products.

Flexibility

The readiness for lifelong learning and the permanent interest in new technological trends characterise our engineering team.

Industrial communication and the electrical complexity of everyday life have moved to a new level and are still developing rapidly. We keep an eye on all new technologies, new applications, new materials and pioneering innovations that can improve or reinvent our products. For example, you can choose from fibre brush and fibre brush technology, different materials such as aluminium and plastic and precious metal contacts such as the silver-to-silver and gold-to-gold multi-contact. We are fully aware of the growing importance of reliable and maintenance-free signal and power transmission in the context of Industry 4.0. In the future, almost every component will no longer fulfil just a mechanical function, but must also be able to transmit data and other signals. For this purpose, we rely on brush technology with low electrical noise, for the transmission of field buses with high data rates, low contact pressure for a llong service life and freedom from maintenance.

Innovation

Flexibility is not just a word for rotarX, but the basis of our corporate organisation and slip rings. Flexible sales and R&D structures with capacities for extensive project requests from our customers are just as available as flexible production structures with large-scale production and fast-track options for small-volume orders. Cable lengths are free to define. Thestandard protection class IP51 we also deliver higher on request. The number of rings can also be flexibly designed. If you have special customised requirements, we will be happy to advise you on the most suitable recommendation for your specification. Therefore, all’ our slip rings are not only available as a standard variant, but also as a modularly designable slip ring system.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.