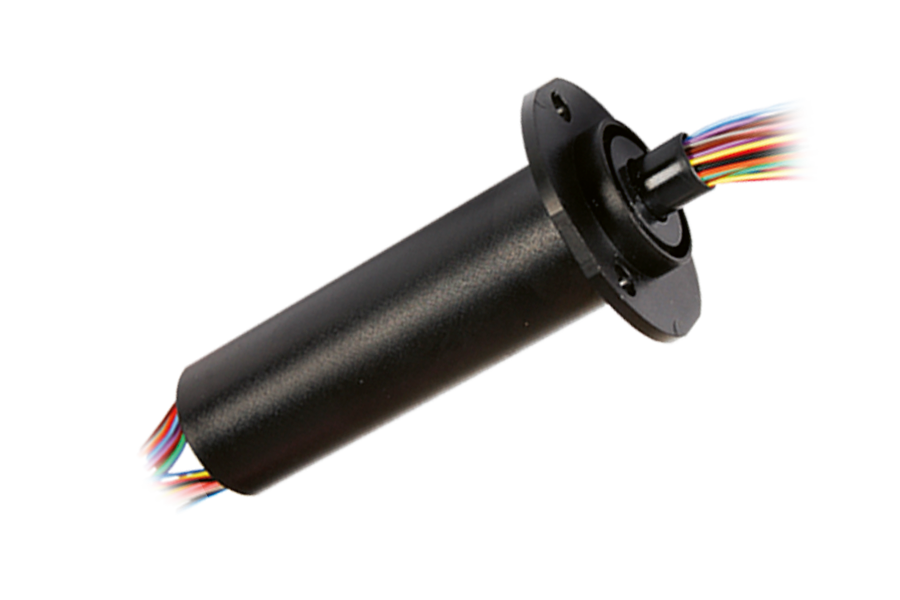

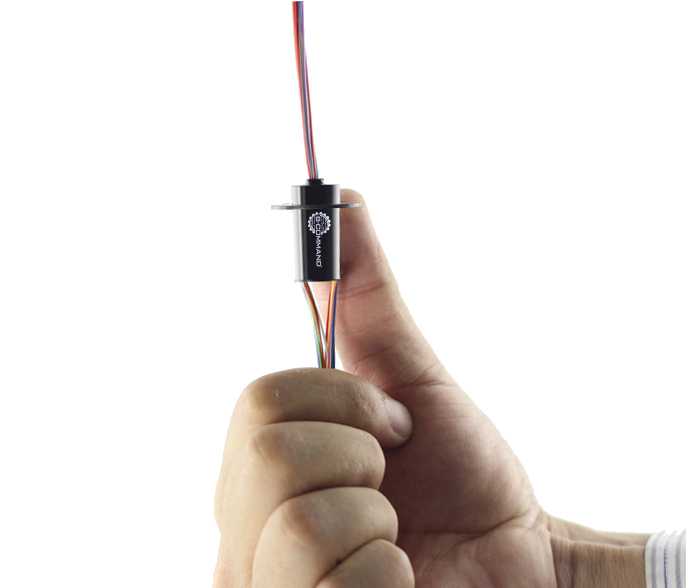

rotarX Capsulated Miniature Slip Rings for Power- and Signal Transmission

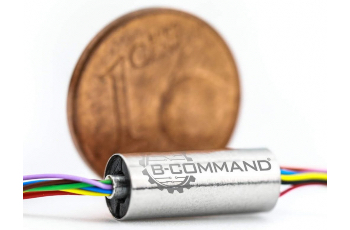

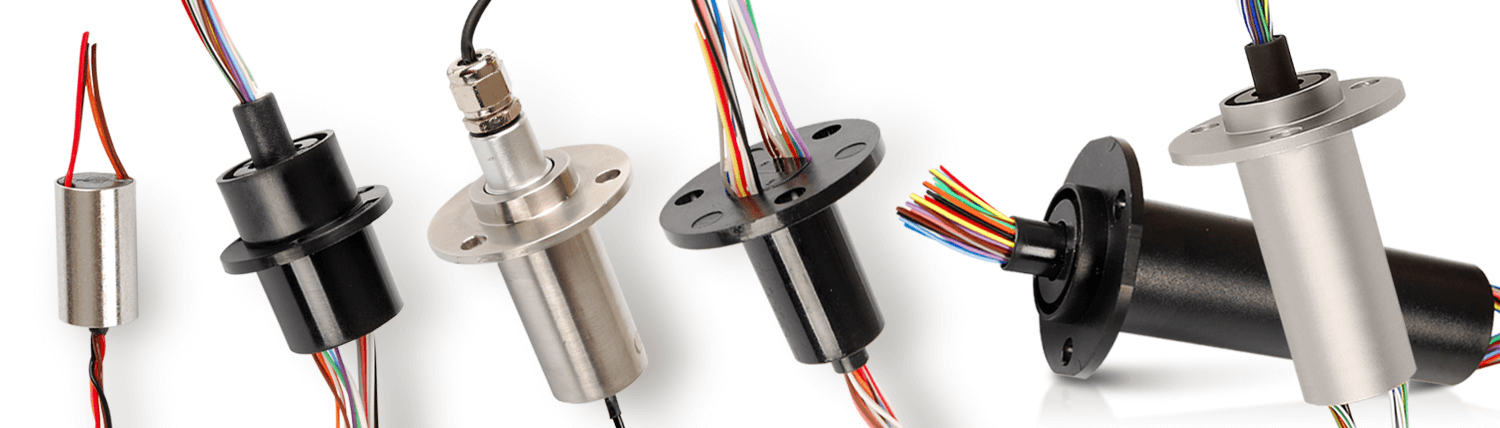

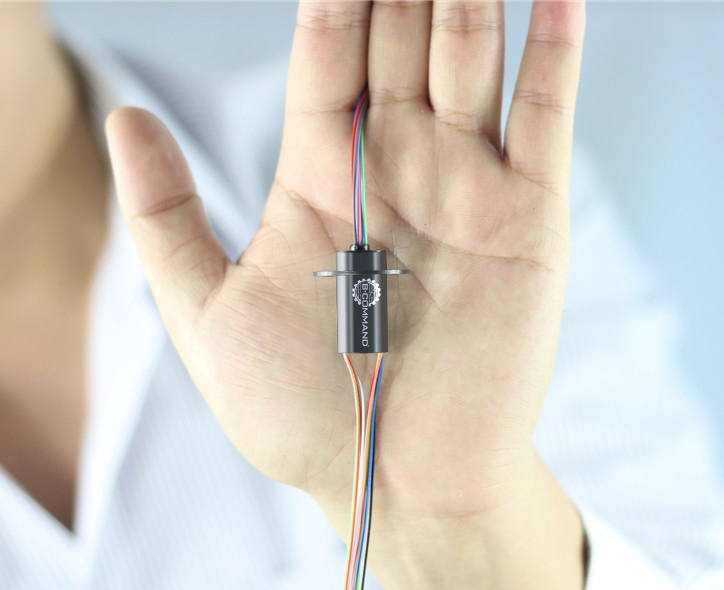

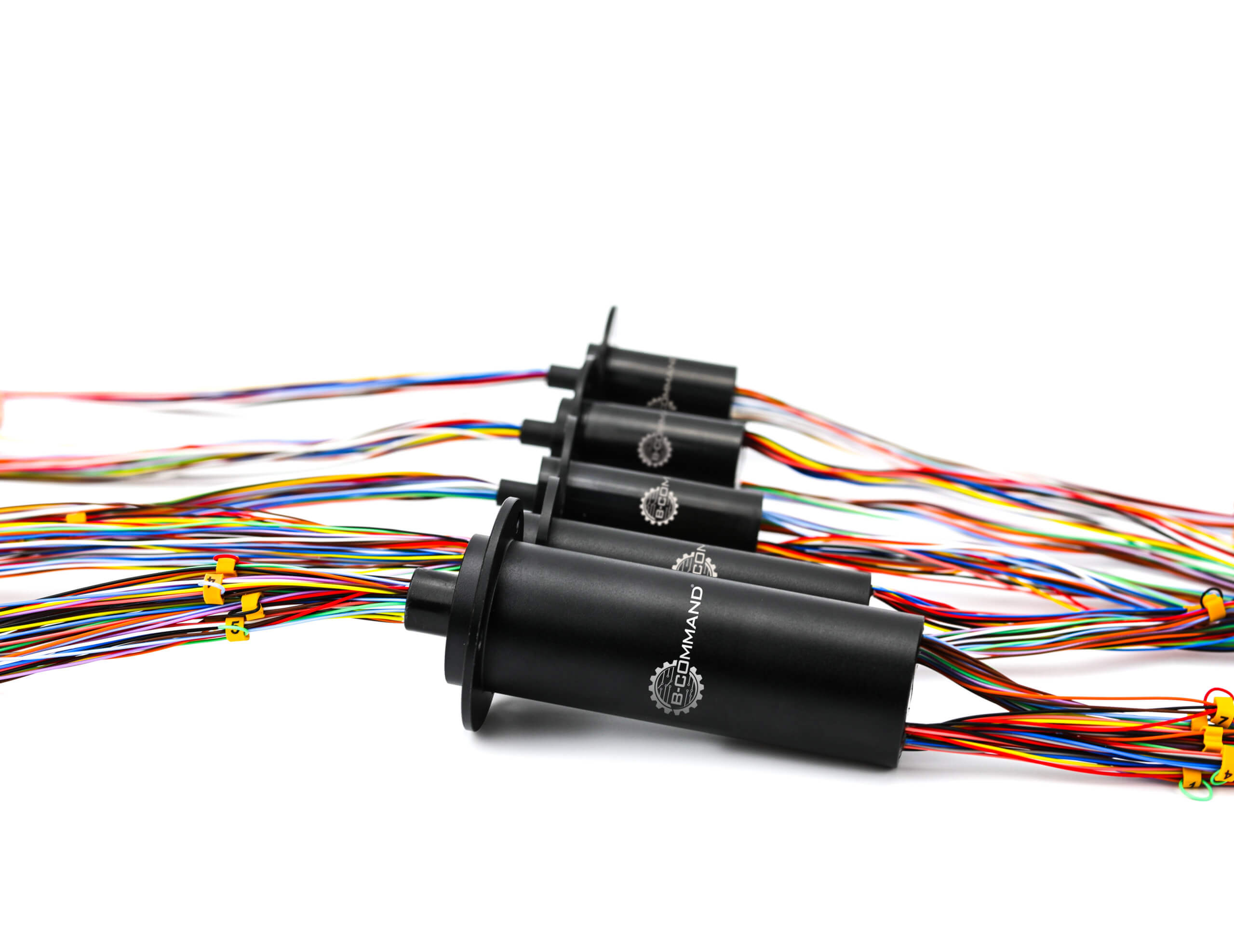

Compact Slip Rings with outer diameter from 5.5mm to 54mm

Technical Characteristics

Electrical Specifications

- Number of rings: 3-125

- Life: 3 million to 100 million revolutions

- Nominal current: 1-10A per ring

- Transmission of fieldbus signals, Ethernet, USB, video signals, temperature and many more

- Combined solutions power + signals possible

- Working voltage: 240 VAC/DC

- Voltage withstand: ≥500V @50Hz

- Electrical noise: max 35mΩ

- Isolation resistance: 1000 MΩ @ 500 VDC

Reliable Power and Signal Transmission through Capsulated Miniature Slip Rings

Wherever current is to be transmitted between a stationary and a rotating component, Slip Rings are still the reliable components of choice. Although there are also contactless transmission options available in the field of signal transmission, such as Bluetooth, infrared or radio, these still have disadvantages such as susceptibility to interference radiation, which rule them out for many applications.

However, at the latest for the transmission of electrical energy, contact transmission is practically without a sensible alternative. The only options for contactless power transmission are arcs, which are highly susceptible to wear, or inductive systems, which require high voltages.

Neither is technically feasible with the sizes offered by the miniature slip rings. In addition, these components offer numerous other advantages.

Capsulated Miniature Slip Rings

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Functionality of Capsulated Slip Rings

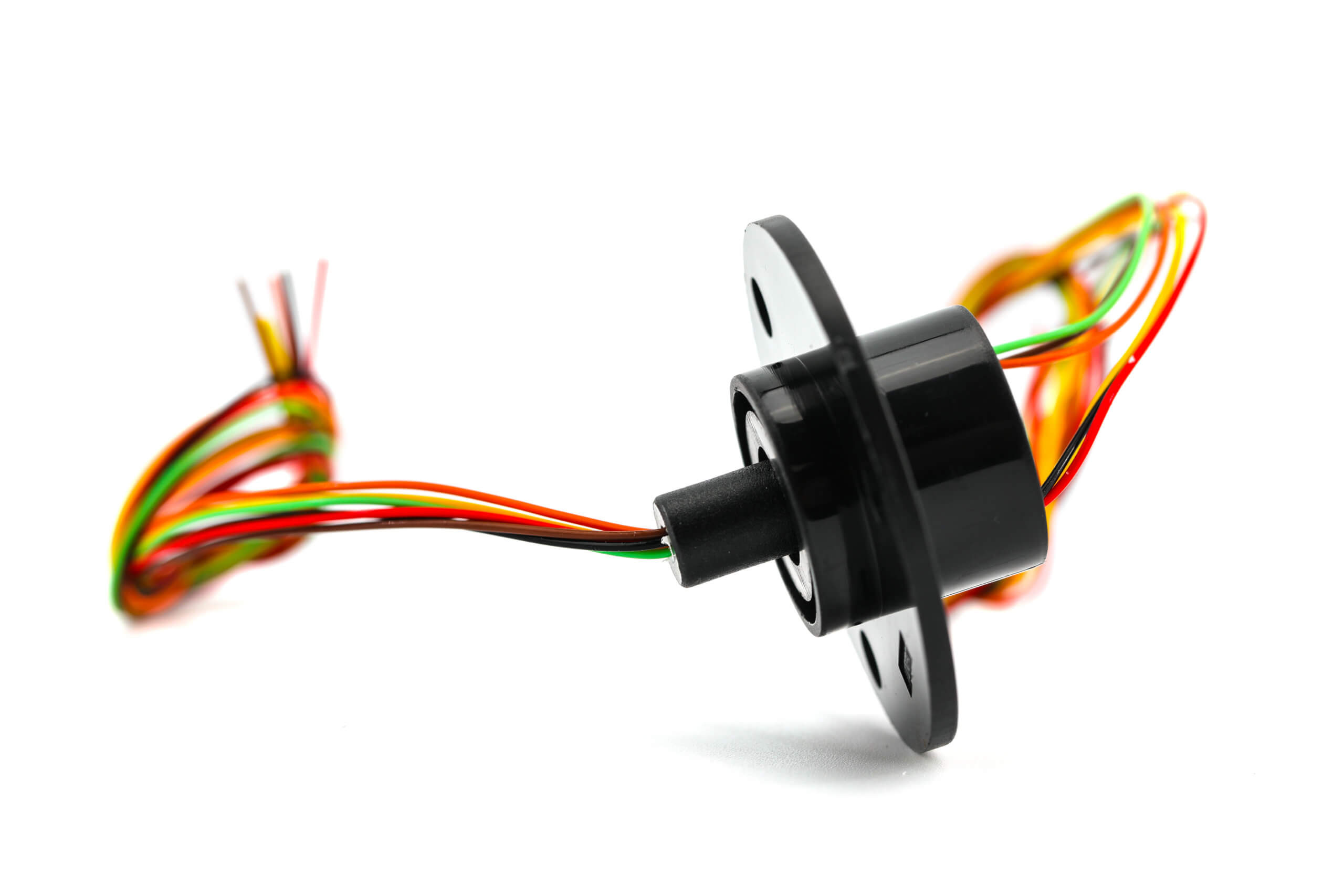

Encapsulated miniature slip rings consist of a rotating and a stationary part. A series of contact rings are attached to the rotor, which are insulated from each other. To the inside, the contact rings are connected with an insulated cable, which is led out of the slip ring to the front. Signal cables also run in at the stator part, which end in sliding contacts.

Ingoing and outgoing cables always have identical colours, so that confusion-free assignment during installation is guaranteed. The sliding contacts touch the contact rings of the rotor inside the slip ring. The contacts are reinforced by a spring, which ensures reliable signal transmission within the technical parameters of the component.

No matter at what angle the rotor is turned in relation to the stator, the transmission of signal or power current is always maintained in this way. The encapsulation serves to shield the sensitive inner workings of the slip rings from external interference.

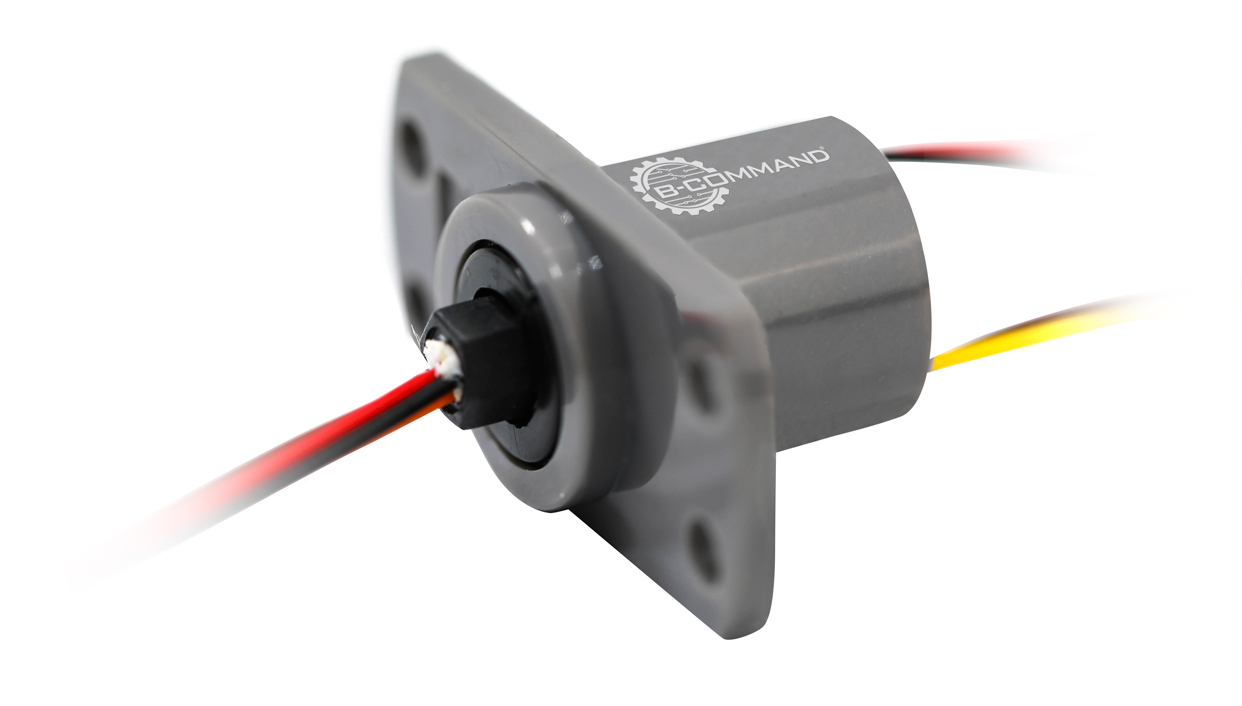

Everything that goes into a slip ring is a part of the design.All you have to take care of during installation is that the slip ring is positioned exactly in one axis with the rotating component. For this purpose, robust flanges with pre-drilled guides for the retaining screws are often attached to the encapsulated miniature slip rings.

Advantages of Capsulated Slip Rings

The encapsulation protects the inner workings of the slip rings against the following disturbances, depending on the level of protection and enclosure material:

-

- Intrusion of dust

- Ingress of moisture

- Electrical interference

- Vibration

- Slip

- Shocks, blows and vibrations

Ingress of dust, especially electrically conductive metal or coal dust, will cause short circuits in a very short time. Since the contact rings and the sliding contacts are not insulated, they react extremely sensitively to penetrating dust. Non-conductive dust can settle on the rotating components and form an undesirable insulating layer.

Penetrating moisture can cause corrosion on the contacts. To ensure maximum operational safety, the contact rings and the sliding contacts are coated with silver. This metal only forms a thin oxidation layer, which immediately removes itself through normal operation of the slip ring. Alternatively, the surfaces can be provided with a gold alloy, which has a positive effect on signal transmission quality and prevention of oxidation.

Electrical disturbances penetrate less into the slip ring, but they can escape from it. Any slight loss of contact can cause an arc, which emits a radio signal. This radio signal can interfere with surrounding components, especially those with wireless signal transmission. The encapsulation prevents these disturbing emissions and shields them reliably.

Finally, the encapsulation is designed to be so robust that it is largely insensitive to mechanical stress. For particularly demanding environments, we also offer enclosures made of stainless steel. These are also ideal for hygienically critical environments. Stainless steel can be disinfected very well and has aseptic properties.

Variations of Capsulated Slip Rings

We offer capsulated miniature slip rings of three and up to 125 transmission lines. Each ring can handle rated currents from 1 to 10 amperes and operating voltages from 12 volts to and 440 volts. This gives you complete freedom to choose which line you want to use as power current for operating consumers or as signal current for sensors. As a reserve you have a dielectric strength of up to 500 volts at your disposal. This means that even larger voltage peaks are reliably intercepted. Our slip rings work optimally in a temperature range of – 20°- +60 °C. If you are planning an application outside this temperature range, please contact us. We will find the right solution for a safe and reliable slip ring even for your special challenges.

Installation of Capsulated Slip Rings

We have made the installation of the capsulated miniature slip rings as user-friendly as possible. The slip ring is attached to the flange of the housing with the pre-drilled holes at the desired position. The flange can be designed as rotor flange or stator flange and the included mounting holes can also be customized. Make sure that this position is always exactly in the center of the rotation axis. Slight eccentric movements can still be intercepted. Larger deviations may cause mechanical stress on the ball bearing, which may have a negative effect on the service life. The colors of the incoming and outgoing cables are identical. Mix-ups are impossible. After installation of the slip rings and connection of the current-carrying lines on both sides, the slip ring is ready for use.

Use of Capsulated Slip Rings

These components are designed to establish a reliable electrical connection between a stationary and a rotating component. For this purpose, our capsulated miniature slip rings always offer maximum operational reliability at low cost. By using the capsulated miniature slip rings, you get an excellent safety reserve for unforeseen failures even in seemingly uncritical environments. Our capsulated miniature slip rings are therefore an extremely cost-effective contribution to increasing the operational reliability of your systems. In particularly demanding applications, such as aviation, space travel or the handling of chemicals, the capsulated slip rings make a significant contribution to general operational safety. Reliability, robustness and power reserves characterize each of our components.

Maintenance of Capsulated Slip Rings

The capsulated miniature slip rings are maintenance-free. They cannot be disassembled. The components are pressed and capsulated at the factory in such a way that they provide consistent reliability and transmission quality over their entire service life. Afterwards, the inexpensive components can be easily exchanged and replaced with a new part. Apart from external cleaning and regular checks of the non-locking rotatability, the capsulated miniature slip rings require no maintenance work.

Your way to the Capsulated Miniature Slip Rings

With the encapsulated miniature slip rings, we offer you the ideal components for transmitting power and signal current to rotating components. Our comprehensive product range also has the right solution for your applications. If you have any questions about your encapsulated miniature slip rings, please call us or use our contact form. We will work with you to find the ideal encapsulated slip rings for your applications.

We can supply you with quantities from 1. Special shapes or special types are possible on request. Give us a call. We will discuss your challenges until we have found your optimal slip ring. Trust our competence and experience. Our encapsulated miniature slip rings are used in tens of thousands of applications worldwide. Whether it’s a one-off production or a series component, we supply encapsulated miniature slip rings that you can fully rely on.

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.