robotics

Rotary Joints for Multi-Axis Transmission of Power and Data

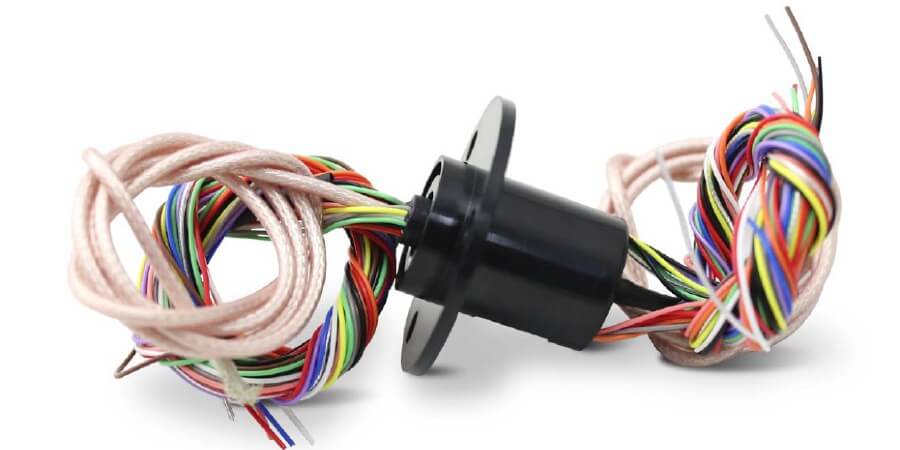

The robots are designed according to the requirements of the respective production situation. This often requires multi-axis systems that move the production material to the predefined positions. The rotarX slip rings from B-COMMAND have been designed to transmit the power and data of the individual drives and to connect the sensors in all sections of the robot arm. Fast rotation speeds, maintenance-free design, high temperature resistance and extremely compact dimensions characterize our rotary joints.

Typical robot applications for slip rings:

- Pick and place robot for waver production

- waterproof small robots for machine tools

- Cleanroom robots for food and pharmaceutical industry

- Palletizing robots for various handling tasks

- Lightweight robot for human-machine cooperation

- Industrial robots for automotive production, welding robots

- medical robots for surgical technology

- Inspection robots for pipelines and pipes

Advantages of rotarX Slip Rings for Robots:

- modular design and flexible adaptation to different machine types

- compact dimensions

- Hybrid slip rings for combined transmission electrics + coax or electrics + hydraulics/pneumatics (media feed-through)

- long service life up to 100 million revolutions

- high data rates for data transmission in bus networks

- Operating temperatures from -40°C to 80°C

- simple installation

With its 14 different slip ring series, the rotarX slip ring family from B-COMMAND offers the right solution for every robot. The modular design of the rotary transformer and the adaptation to the respective customer application is a matter of course for us. In close cooperation with our customers we develop tailor-made solutions for robotics.

A wide Range of Tasks for Slip Rings

The range of robot applications is now very wide in many areas and the slip rings are assigned special tasks in addition to the classic transmission of power and data. Slip rings for channel robots are therefore often produced with special attention to the transmission of HD video signals and are sometimes supplied with KOAX bushings. Slip rings for maritime applications are implemented in seawater-resistant housings with high protection classes. Miniature slip ringswith a housing diameter of only 6mm can ensure reliable transmission even in very space-critical situations. Slip rings for welding robots are designed for higher amperages in order to transmit all power elements required for the welding process. Slip rings with hollow shafts offer space for the passage of ropes, cables and lines for liquids or gases. Depending on the requirements of the robot technology, diverse requirement profiles can also be combined in hybrid slip rings.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.