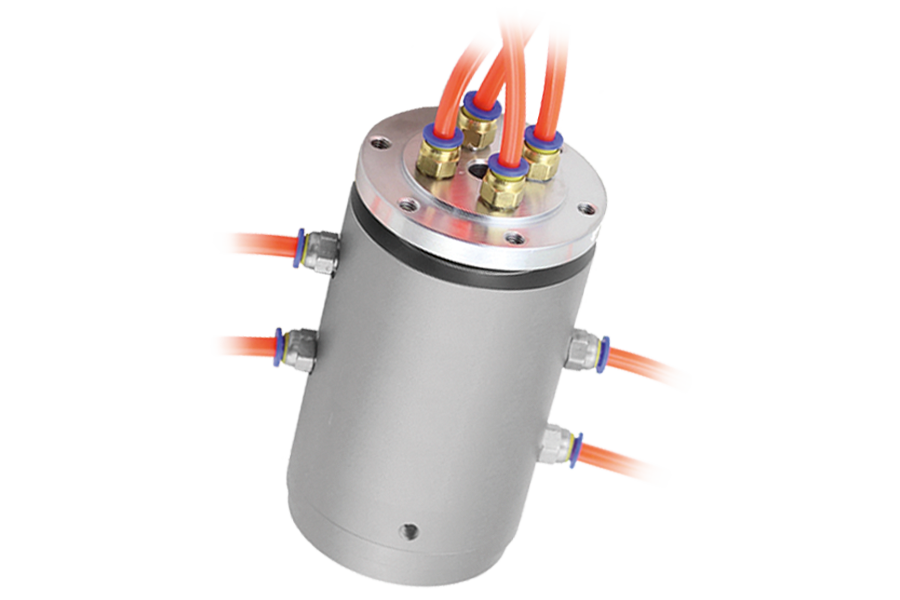

Rotating unions up to 300 bar for large hydraulic excavators & construction machinery

Individually configure multi-channel rotary unions for wheeled and tracked excavators

Whereas with Chain excavators often only between four and six channels are required for the two oil motors and hydraulic power unit, require Wheel excavator Rotating unions with significantly more channels for motors, brakes, dozer blade, steering and support.

In addition, the housings of the rotating unions require a High resistance (IP protection class), as they are usually used in machines that are used in rough, muddy and dusty working environments. You can therefore freely choose from different protection types and enclosure materials, as well as different seals to tailor the component perfectly to your individual area of application.

In addition, the rotating unions can also be used for other media such as Gas, vacuum, water, oil or other liquids, which have to be carried out at high pressure. Since up to XX channels possible, these can be transmit different media at the same time while individual configuration options ensure that they are all reliable and low-wear, but sharply delineated from each other can be used. This enables, for example, the Combination of leakage oil line, as well as supply and return line in one rotating union at Chain excavators.

At Wheel excavators compressed air is transferred accordingly with the aid of the pneumatic rotary unions, while at the same time the transfer of other fluids such as brake fluid and hydraulic fluid for support and steering may be necessary.

The standard installation is carried out via a Flange mounting with individually adaptable hollow shaft. The rotation speed is up to 130 revolutions per minute.

Technical data

Electrical specifications

- Number of rings: 2-80

- Rated current: 5-10A per ring

- Max. Working voltage: 440VAC/DC

- Dielectric strength: ≥500V @50Hz

- Electrical noise: max 10mΩ

- Insulation resistance:

≥1000 MΩ @ 500 VDC

More about the general functioning and possible combinations of housing, seal, rotor shaft and screw connection of a Rotating union you can read in the linked article.

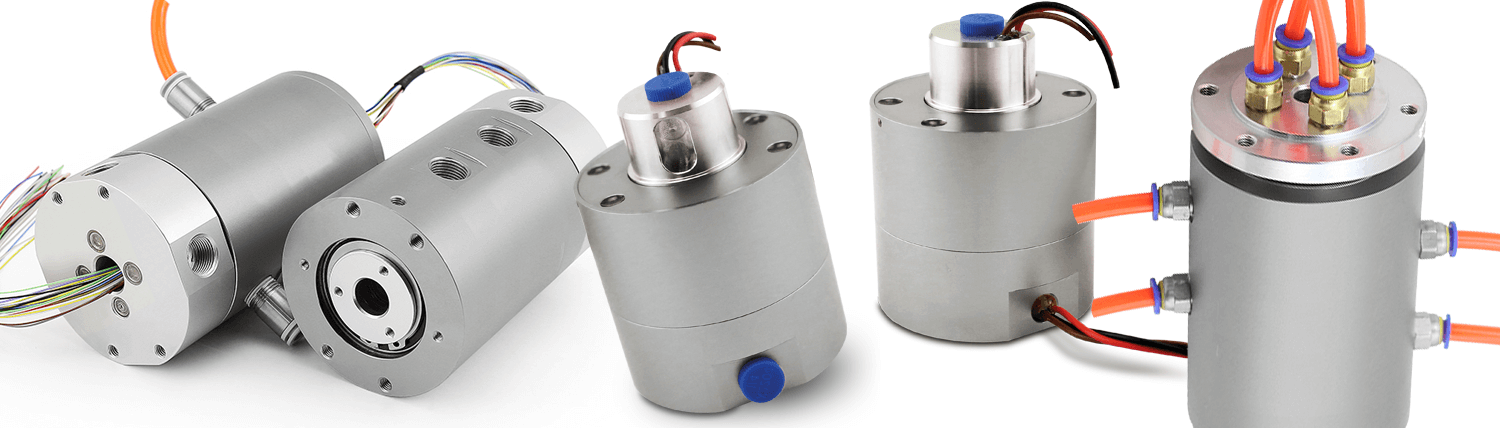

Hybrid electric rotating unions In addition, the return line, the line for leakage oil and the supply line for hydraulic oil, as well as the Transmission of sensor data for measuring the level of a hydraulic oil reservoir in just one component. And that is just one example. In cranes, for example, position data and control signals can be transmitted in addition to fluids. So you combine electrical, pneumatic and hydraulic rotary transmission in just one swivel joint. The Saves space, weight and costs.

For example, also Data and signals important for the control block for temperature and pressure monitoring and the control of valves, such as feed valves for compensating for leakage oil losses, can be transferred in order to allocate the oil to the individual consumers more efficiently and reduce wear.

Hybrid pneumatic/liquid + electric

Why do excavators actually need rotating unions?

In order to understand this, we will briefly inform you about the general functioning of modern standard excavators with a 360-degree rotating upper carriage, the undercarriage with crawler or wheeled undercarriage and the boom with bucket or bucket.

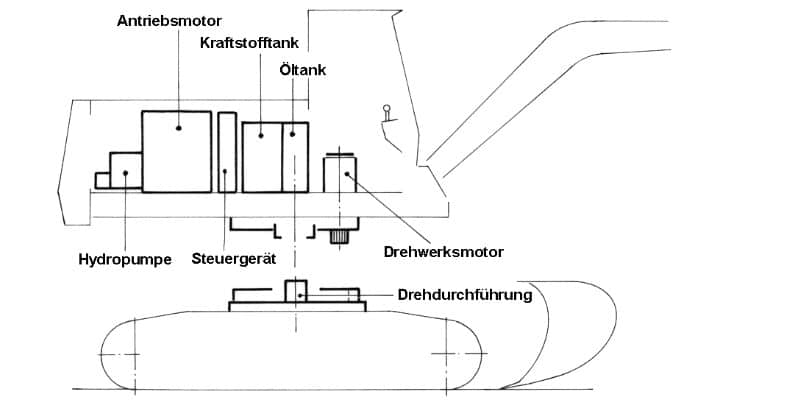

The drive engine, usually a diesel engine, and the hydraulic unit are located in the superstructure. This engine drives hydraulic pumps that supply the oil for the boom and the undercarriage. For this purpose the Oil from the tank, via the pump, to the control unit, to the consumer and back to the oil tank again. (return oil, leakage oil).

For this it is necessary that the fluid – in this case hydraulic oil or pressure oil – is transferred between rotating components and non-rotating components. At the same time, the superstructure or tower slewing ring must be able to rotate without twisting lines. And where components have to rotate, hydraulic motors are used to translate the oil pressure supplied by combustion engines in the superstructure into rotary movements.

Since there are two different pressures in this working circuit, namely the working pressure at about 300 bar and 30 bar in the control oil circuit, there are separate control oil pumps for the latter. This is also the reason why rotating unions for hydraulic excavators must be suitably resistant.

How does the oil get from the superstructure to the hydraulic motors?

But how does the oil from the superstructure get to the hydraulic motors of the undercarriage? And how does the return oil get back into the superstructure? This is not possible with normal hoses, as the upper carriage can rotate 360 degrees an infinite number of times. After just one rotation, normal cables or hoses would twist or tear off.

Right here come Rotating unions for use. The housing is mounted on the superstructure and sits in the centre of the slewing ring. This transfers the pressure oil to the stationary hydraulic motors via the rotating slewing ring with the help of ring channels. For this purpose, a stationary piston is mounted on the undercarriage, which rotates in the housing and is connected to the hydraulic motors via several holes or Channels has at its disposal. With a Tracked excavator these are usually at least five, namely two for the supply of the oil to the engine, two for the return oil, back into the upper carriage and one for the Leakage oil. The two components are connected to each other via ball bearings.

In addition, there is a slewing gear motor in the upper carriage that drives a pinion. This in turn meshes with the concealed internal gearing of the slewing ring on the undercarriage so that it drives the upper carriage as soon as the pinion rotates.

In the case of a wheeled excavator, considerably more ducts are necessary, as steering fluid, brake fluid and compressed air for the tyre pressure control system and support must also be transferred.

Configure rotating unions

The design of the rotating union is based on the number of oil lines to be fed through, the expected volume, the maximum working pressure and the required speed of rotation.

Seals and housings are adapted to the media to be passed through and the speed of rotation. For example, there are rotating unions that have to realise several thousand revolutions per minute and require correspondingly robust seals (such as mechanical seals). In the case of low-speed hydraulic excavators, less complex sealing systems are usually necessary.

In addition Seal and housing adapted to the working environment and media The rotary union must be able to handle all media that are to be conveyed to and from the rotary union, such as compressed air, gas, oil, emulsions and greases, and even toxic media.

Here it already becomes clear that individual configuration options are absolutely necessary in order to be able to tailor the rotating union perfectly to your construction machines and areas of application. There are big differences between wheeled and tracked excavators alone due to the different media and fluids. And the maximum working pressure and volume also vary depending on the size of the excavator or crane.

The bushings installed in the excavator have more or fewer connections and annular spaces depending on the number of functions of the undercarriage, which also increases the overall length of the bushing.

Therefore, it is best to use our online configurator or contact our experts to configure the ideal solution for you.

The various rotarX slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value. Premium Engineering Slip Ring Solutions.Do you already know our configurator?

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.