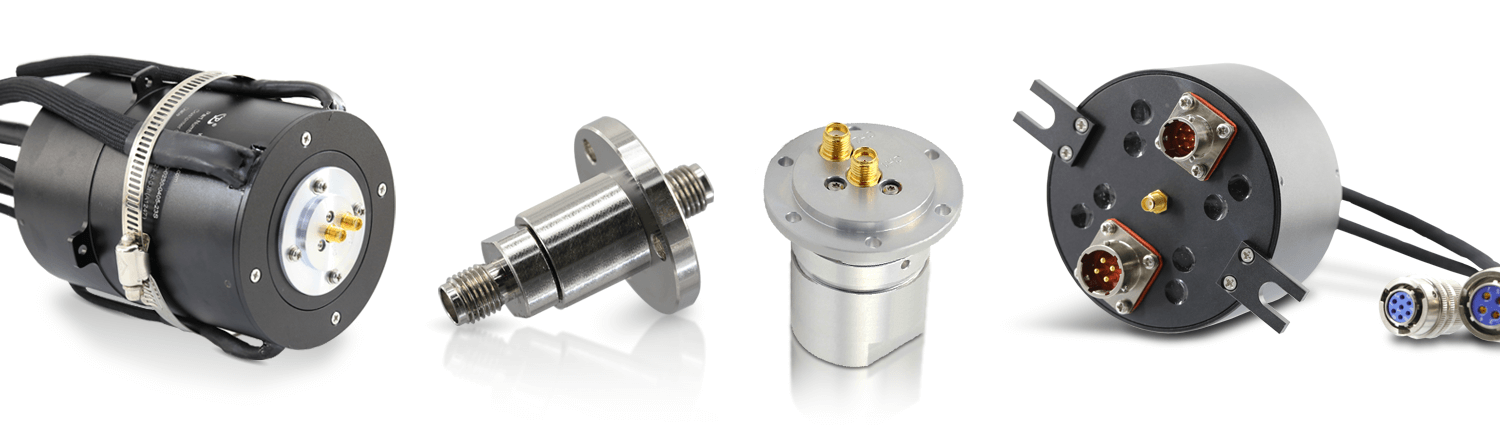

Slip rings for coaxial transmission including power, data and signals

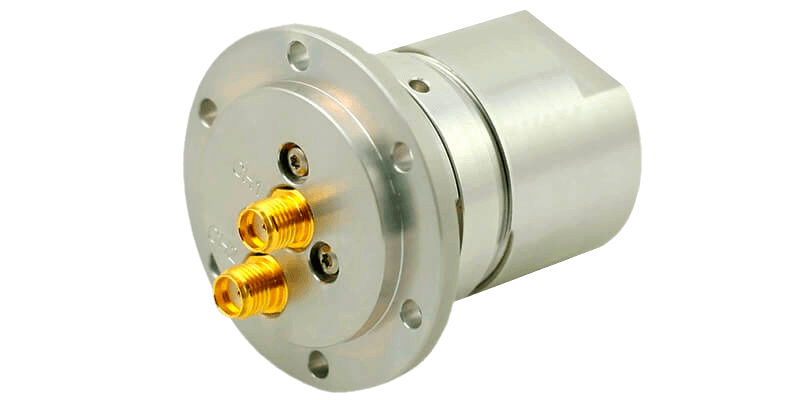

Compact slip rings with up to 4 coaxial lines

Technical Specifications

Electrical Specifications

- Number of rings: 2-72

- Nominal current: 5-10A per ring

- Max. Working voltage: 440 VAC/DC

- Voltage withstand: ≥500V @50Hz

- Electrical noise: max 10mΩ

- Isolation resistance:

≥1000 MΩ @ 500 VDC

Coax Slip Rings

Coax slip rings (or COAX) for signalling and more. The coaxial cable gets its name from its structure. Instead of a strand of bundled wires, the current-carrying paths in a coaxial cable lie inside each other. The concentric, onion-shaped cross-section is called coaxial because two cable axes are built into each other. The outer cable axis consists of a stainless steel or copper braiding. This keeps the coaxial cable very pliable and flexible. The inner cable, which is positioned exactly in the centre, is a conventional, monolithic copper cable.

Between the two current-carrying lines there is a dielectric as an insulating protective layer. It prevents short circuits between the lines. Suitable hoses made of soft plastic or rubber are used for this purpose. From the outside, the cable is usually particularly well protected against moisture penetration. This is also necessary because of the thin copper wires of the outer cable, as they would otherwise quickly rust.

The coaxial cable has proven itself above all in signalling technology. It has good self-shielding properties and is insensitive to interference signals. Above all, it is suitable for transmitting signals over a long distance with almost no interference. In the household, the coaxial cable is therefore known as the connection cable between a satellite system and the television. In industry, the coaxial cable plays an important role, especially in automation and data transmission technology. It is usually located between the interfaces of radio receivers and transmitters and a sensor or actuator that is to be moved by wireless signal. Here there is often a need for rotary joints. The coaxial slip ring was developed so that the transmission capability of the coaxial cable is not reduced even with rotary joints.

Coaxial Slip Rings

Functionality of coaxial slip rings

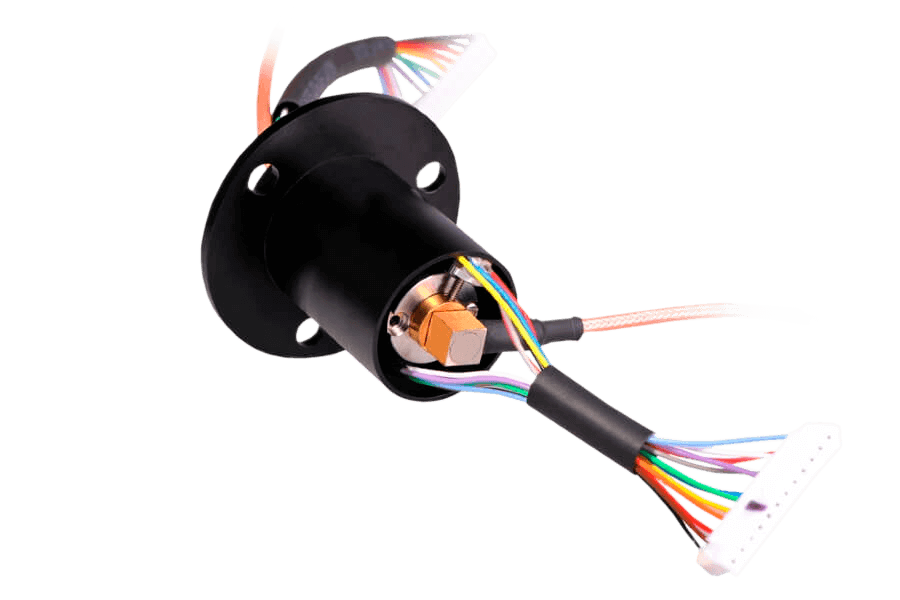

rotarX offers the coax slip rings as hybrid slip rings. This allows you to have other signal and/or power feedthroughs in addition to the coax feedthrough. The coaxial feedthrough consists of one to four coaxial connections on the inner, stationary part of the coaxial slip ring. The signals are transmitted to the rotatable outer rotor via special gold-gold brush contacts. Modern fibre brushes are installed in the coaxial slip ring for the signal transmission of the coaxial impulses. They guarantee a constant transmission quality of the signals.

Advantages of rotarX coaxial slip rings

Our coaxial slip rings have the following advantages for you:

- designed for coax applications

- stable housing made of robust aluminium

- high load capacity according to IP51, higher on request

- Rotates up to 150 revolutions per minute

- Corrosion resistant with gold-gold contacts

- Available in many variants

The compact and high-strength aluminium housing makes the coax slip ring insensitive to corrosion and UV radiation. The screw lug integrated on the inner stator is also made of this proven metal. This makes the coaxial slip ring 100 % corrosion-resistant. With the screw tab, the “anti-rotation tab”, the coax slip ring can be mounted on any surface.

The housing is shielded against active and passive radio interference. This is particularly important for coax slip rings, as this type of cable is mainly used for signal transmission. The standard coax slip ring can be rotated up to 150 revolutions per minute. The large selection also has the right coax slip ring for your application. With protection class IP51, the slip ring is insensitive to penetrating dust and splash water. This protection class is sufficient for most applications. If your applications require higher protection, please contact us. We will also find the right coaxial slip ring for your challenges.

Coax Slip Rings Offer

We can offer you coax slip rings with one to four coax feedthroughs. In total, a coax slip ring has up to 72 feedthroughs. Each ring has a maximum through voltage of 440 volts, regardless of whether it is direct or alternating current. This means that you still have a small reserve for the maximum dielectric strength of 500 volts. The coaxial slip ring keeps the electrical noise to a maximum of 10 milliohms. The insulation resistance or dielectric strength is designed for 1000 megohms at 500 volts DC.

Without customer specifications, we deliver the coax slip rings with incoming and outgoing cables in a length of 300 mm. Other lengths can be produced at any time. With a working temperature of -30 °C to +80 °C, the coax slip ring can also be used in extreme environments. If you have any special requirements for your coax slip rings, please let us know.

Using the coaxial slip rings

The installation of the coax slip rings is easy. They are simply screwed to a solid base with the lug and connected to the cables. Ideal for their attachment are fits that are easy to make yourself. To avoid confusion, all incoming and outgoing cables have the same colour pattern. If the coax slip ring is mounted on the stator side on a rotating component, for example a hollow shaft, you should ensure that it is positioned exactly in the centre. In this way you avoid undesirable twisting.

Use of the coaxial slip rings

Coax slip rings are used to reliably transmit high-energy radio signals, which are common in coax cables. This limits their rotational speed. Higher speeds would provoke spark jumps in the slip ring, which then lead to interference signals. Most applications of coax slip rings are therefore very slow and also do not use the entire angle of rotation. Typical applications for the coax slip ring are as follows:

- Camera and security systems for commercial use

- Medical scanners or scanners for baggage screening

- Underground mining and petroleum extraction

- Automation technology

- medical applications

- Sensor technology

- Avionics

- Defence and construction vehicles

- Radar systems

- Drone technology

- SATCOM

- Wind energy

Repair of the coaxial slip rings

Coaxial slip rings are precision-manufactured components for a precisely defined application. They are designed ex-works to fulfil their purpose trouble-free over their entire service life. Disassembly would counteract this purpose. The coaxial slip rings are therefore not designed for internal maintenance. However, we can offer you an exactly calculated service life of the coaxial slip rings for each application. So you know exactly when you should replace your slip ring as a precaution. With our favourable prices, the change to a new slip ring is also particularly easy.

How to get your coaxial slip rings

Our wide product range has the right coaxial slip ring for most applications. However, if you have special requirements, please contact us. We will find the ideal solution for your challenge in a joint discussion. We look forward to your call!

Practical slip ring solutions for your application

Product catalogue for all slip rings

Find out about the different slip rings in our current overview. Transmission technology for complex industrial and safety-relevant applications form the core of our product range. All products can be individually adapted to the applications in order to offer you added value. Premium engineering - that is our claim for every single product we manufacture. We would like to convince you of this.

Do you have questions or would you like advice?

You can reach us Mon - Fri from 8 am to 5 pm.