At rotarX, we are passionate about slip rings and are experts in finding the right solutions for our customers. But we also understand that not everyone is as passionate about them as we are. In this blog post we have compiled three important facts about how slip rings function, to help you better understand this piece of technology.

What is a slip ring?

A slip ring is an electromechanical device used to transfer an electrical signal from a stationary power source, toa rotating component. To enable this transfer, the slip ring uses a carbon brush, which rubs against the outer diameter of either the stator or the rotor to transfer current, while enabling rotation. The three main parts of a slip ring include the stator, rotor, and the brush. These are connected with joints and are easily detachable before being placed. It’s important to note that once the slip ring is in place, its position can’t be changed. Despite their basic design, slip rings perform a very important function.

Fact 1: Slip rings protect machinery wires

Slip rings solve a common problem in the electromechanical industry. Within machinery there are complex networks of wires that move power from one part of the machine to another. If any of these wires become loose or exposed, it may lead to breakdown. Before slip rings, it frequently happened that wires were getting stretched or torn apart by the rotor, short circuiting the machine. Using slip rings, this problem is completely eliminated by the protective encasement of the wires.

Fact 2: Slip rings need routine maintenance

Typically, slip rings consist of a graphite brush which rubs against the outer diameter of the metal ring. In comparison to other metals, like copper, this generates less heat and noise, and extends the lifetime of the slip ring. Due to the constant friction due to the rotation, there is going to be some wear and tear on the slip ring. However, we typically advise you with what the expected lifetime of the ring is like to help you get a sense of the upkeep.

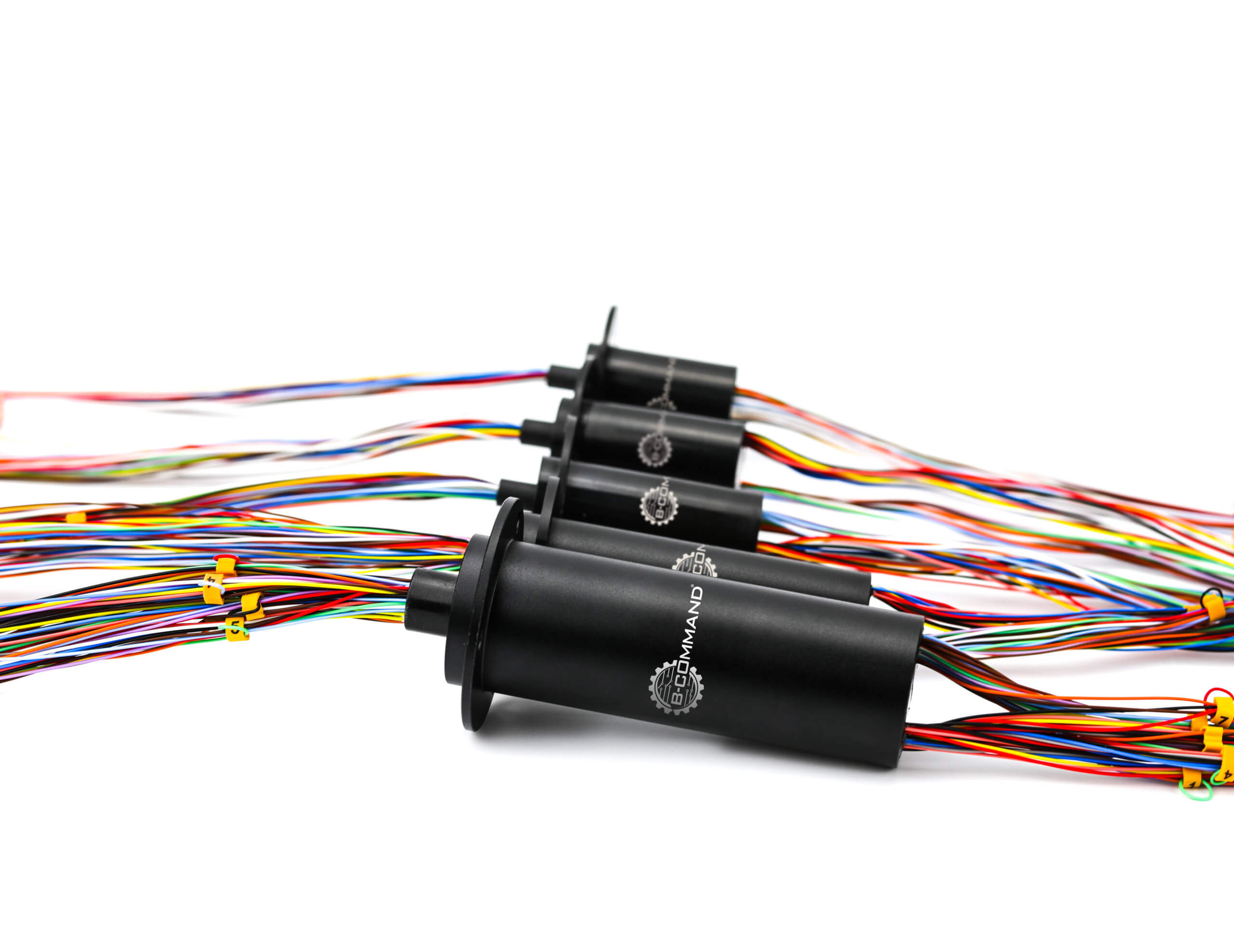

Fact 3: Slip rings are highly customizable

Despite its basic construction, slip rings can be highly customized. Changing different components of the ring, can completely change the application environment and the lifetime of the slip ring. In addition, changing the brush material changes what kind of slip ring it is and makes it fit for use in different operational environments. For example, a mercury slip ring uses a pool of liquid mercury instead of a carbon brush. This offers less noise, less friction, and generates no heat. With through-bore slip rings, the rotating shaft passes through itself and uses a different metal, thus replacing the carbon brush completely. The most recent innovation within slip ring technology is the separate slip ring, which allows even more flexibility in the installation. As a result, this slip ring solution is commonly used within engines where there is an increased need for flexibility.

What did you think about these facts about slip rings? Did you learn something new? RotarX is your go-to partner for slip ring solutions and we specialize in custom solutions. If you are unsure of how to proceed with your project, we would be more than happy to help you find the right solution.