Slip rings and rotary unions are important electrochemical components for commercial and industrial machines. They can be found in a variety of applications where the transmission of power and data is needed from a rotating to a stationary component. Slip rings can be found across industries, from high tech solutions with relatively low-wear, to more heavy duty applications, including oil and gas. In this blog article, we will have a look at heavy duty slip rings and rotary unions, as well as their use in the oil and gas industry.

Heavy Duty Slip Rings and Rotary Unions

Within machinery it is often necessary to connect a rotating component with a stationary one. Slip rings provide a reliable, low-maintenance solution for power, signal, and data transmission. Rotary unions enable the wireless transmission of liquid media, including oil, water, grease and emulsion. Sealing solutions can be found in a variety of applications, and almost all heavy machinery in construction, oil and gas, and agriculture depend heavily on hydraulics. Although slip rings and rotary joints can be produced separately, it is advisable to source both from the same company. This is to ensure a cleaner design and that the components are sealed together properly. As a result of increased demand, new solutions have been developed which allow the simultaneous transportation of two different substances, including water and gas.

Application in Oil and Gas

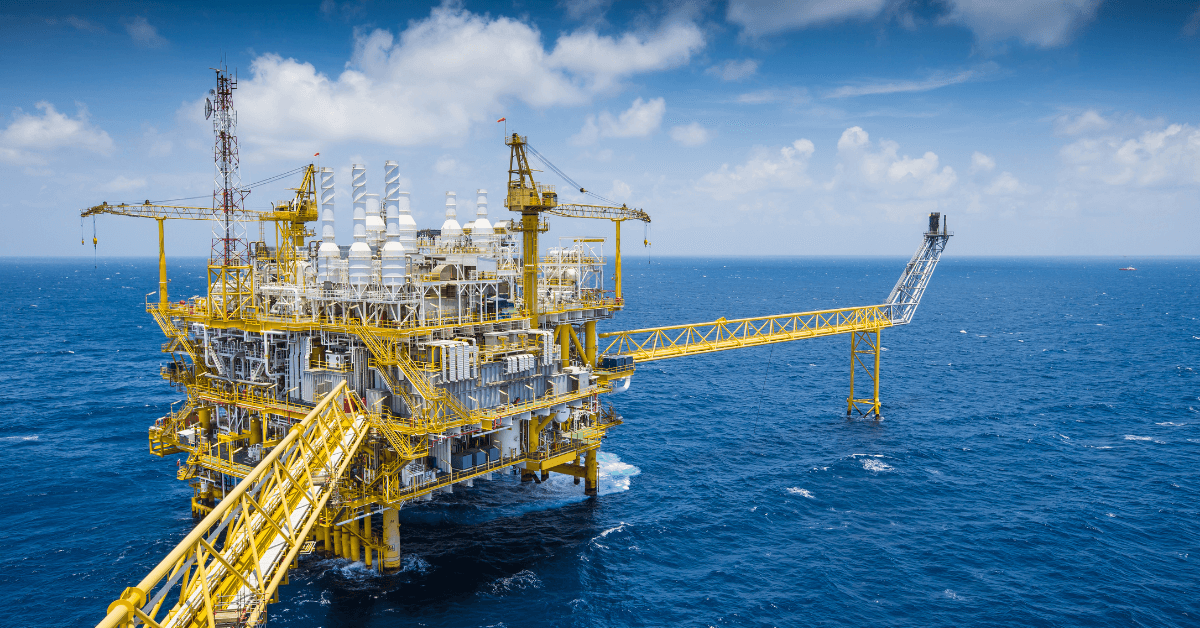

Within the oil and gas industry, slip rings and rotary unions are often used as a seal. The harsh environments of the oil and gas industry put specific demands on the slip rings and rotary unions used. When drilling for new oil and gas reserves, a key component is hydrocarbons which swell and contract depending on the drill site. Some of these conditions include high pressure and high temperatures (HPHT) that condense the technologies used to mine these reservoirs. Due to the changing pressure and temperature of these organic compounds, the slip rings used for this application must be highly specialized. Slip rings and rotary unions are commonly found within drilling equipment, including in offshore oil exploration and fracking technologies.

Products from rotarX

The hybrid pneumatic slip rings from rotarX low-maintenance and durable solution if your application requires the simultaneous transmission of gas or liquids along with electrical transmission. This slip ring contains up to 16 media passages. For electrical transmission, between six and 96 rings can be used for each slip ring.

Like the hybrid pneumatic slip ring, we also offer a miniature pneumatic slip ring for applications where space is limited. These combine both power and signal transmission with media leadthrough. With a diameter of just 36mm, this series is the most compact hybrid slip ring on the market and can be equipped with max. 4 media passages. We offer both a standardized and a modularized design that can be customized based on the needs of the customer.

At rotarX, we understand the demands of difficult environments and our products are designed to optimize both safety and quality of production. We offer a number of highly customized solutions, and will be happy to assist you with your product. If you would like more information or want to schedule a consultation, please feel free to contact us and we are happy to help.