As the technology world continues to evolve, new requirements are placed on the products found in the industrial environments. Slip ring technology is used to transmit power, data, or liquids from a rotating part to a stationary one. This technology is used within engines, including those found in industrial machinery, and cranes. In this article, we will take a deep-dive view into separate slip rings to learn more about this technology.

An Introduction to Slip Rings

Slip rings and rotary unions are important electromechanical components for commercial and industrial machines. They are used to allow a wireless power and signal transmission between stationary and rotating components. In addition to their transmission of power and data transmission, slip rings are also used for the wireless transmission of fluids, including oil, water, grease, and emulsion. Due to their reliable and fast transmission of data, the use of slip rings and rotary unions has significantly increased with the growth of Industry 4.0.

What are Separate Slip Rings?

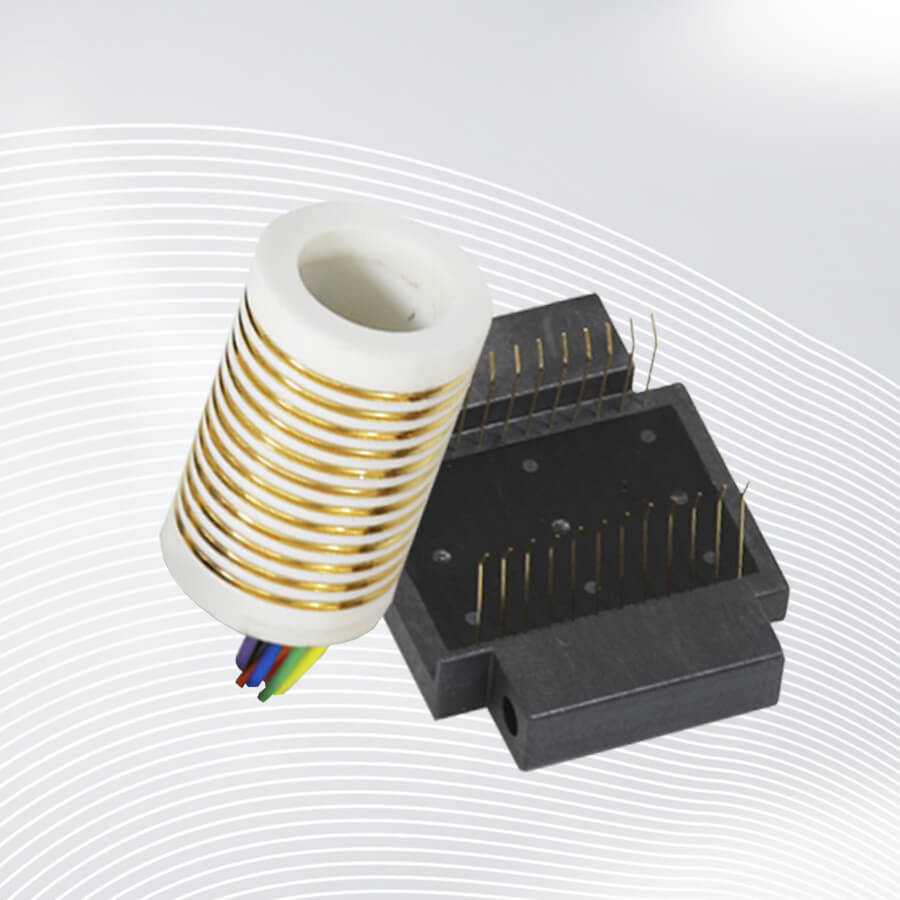

Due to the size of the market and variety of use for the slip ring, a variety of slip rings have been developed to respond to the growing need. The separate slip ring is a relatively new product that was designed to provide a more versatile alternative to the standard slip ring. In this solution, the stator and the rotor components are two different parts and are assembled separately. This gives the end-user full control of where and how the slip ring is installed.

Advantages of the Separate Slip Ring

The biggest advantage of the separate slip ring is the versatility offered by this solution. As the rotor and stator components are kept separate, they can be fitted into a variety of equipment. Additionally, separate slip rings are available in a variety of materials, and the rotor and stator can also be of different materials. This ensures an even higher level of customization, and ensures that the level of electrical noise can be minimized. When considering using a separate slip ring, one thing to note is that this slip ring comes without housing. Therefore, the customer should take care of protecting the slip ring against dust or water to ensure a longer lifetime.

At rotarX, we offer a number of different diameters, from 9.5mm up to 80mm, to accommodate for the different sizes of machinery. We also offer hollow shaft rotor versions so that the rotor unit can be placed on the drive shaft of some machines. The separate slip rings are available with a variety of rings, with a maximum of up to 15 rings. We specialize in providing custom solutions and would be happy to help you find the right slip ring for your application.